The basic skills that are taught in labor discipline classes, for the majority of people, remain just a couple of trinkets for memory. But for some, a favorite hobby begins with the basics of working with metal or wood, which later brings pleasure from the opportunity to show imagination, apply skill and end up with a household item or simply a decorative item. One of these directions folk art is sawing out of plywood, which is also popular among users of the FORUMHOUSE portal. We will dwell on it in more detail in our article, we will analyze what, with what and by what technology real carved masterpieces are created and in what cases stencils are used for cutting. Fortunately, our craftsmen are happy to share their experience.

- Characteristics of plywood

- Tools, templates, assembly

Characteristics of plywood

Plywood – multilayer, sheet construction material, made from hardwood veneer or coniferous species wood by gluing several layers into a single sheet. Due to the peculiarities of the arrangement of the fibers (at one angle), the sheet usually has an odd number of layers - three, five or more. If coniferous varieties There are several types of plywood (fir, spruce, pine), while deciduous ones are mainly birch. There is also a combination - a coniferous “filling” and birch cladding, in which case the plywood will still be birch. The best - completely birch plywood, but it is also the most expensive.

The material is divided into grades and brands, depending on the decorative effect and used in production chemical substances. There are five grades, differing in the quality of veneer and the appearance of the sheets:

- Elite grade (E) - no defects on the surface of the material, uniform, monochromatic, smooth texture without knots, cracks, wormholes or repair inserts.

- First grade (I) – there may be microcracks (up to 20 mm) and knots of small diameter on the sheets.

- Second grade (II) - even fused knots are acceptable if their number does not exceed ten pieces per 1 m² of sheet and their diameter does not exceed 25 mm. There may also be some wormholes and veneer repair inserts.

- Third grade (III) – fused knots without quantitative restrictions, voids in place of fallen knots, up to a dozen wormholes (up to 6 mm) per 1 m² of sheet.

- Fourth grade (IV) - the sheet must have a strong adhesive connection, peeling is unacceptable. The entire spectrum of appearance defects - in almost any quantity, but the diameter of wormholes, knots and voids - no more than 40 mm.

The grade concerns only the outer layers of the sheet and is indicated by two numbers, and the grade can be either common to both sides or vary, more often, within the same grade - I/I I/II E/I and so on. Except for the fourth, lowest grade, all other grades of plywood are sanded on both sides, and the elite grade can be additionally varnished.

Naturally, the higher the grade and decorativeness of the material, the more beautiful it will turn out. ready product. But considering that the cost of the elite, and even the first grade, is decent, and the parts cut out are most often small in size, you can use a lower grade if you actually cut a high-quality blank from the sheet. The plywood from which the workpiece will be cut should not have knots - they may fall out and other defects. They also pay attention to the ribs - you cannot cut out masterpieces using fragments with voids in the middle layers.

The grade of plywood and its main characteristics are determined by the chemical compositions used:

- FB – impregnation of veneer with bakelite varnish, which provides resistance to high humidity.

- BS – bakelite glue (alcohol-soluble), gives high performance characteristics, such plywood is stronger and more durable.

- BV – water-soluble bakelite mixtures; plywood is resistant to high humidity.

- FC – phenol-urea resin bonding, relative water resistance, for indoor use.

- FSF – gluing with phenol-formaldehyde resin, moisture-resistant material for external use.

Which plywood is suitable for sawing

For sawing products intended for home use(boxes, stands, shelves, utensils, decorative elements) best option– FK grade plywood.

Phenol-urea resin is safe for others and well tolerated high humidity, therefore products made from such plywood are not distinguished harmful substances and resistant to deformation.

FSF brand plywood is not suitable for household items due to aggressive formaldehyde, but it can be used for outdoor decoration - carved trims, coffee tables For open verandas or gazebos, various benches.

For cutting, plywood with a thickness of 3–5 mm is most often used. If loads are expected (chairs, stools, benches, tables, etc.), the thickness is increased. It is more difficult to cut from a thick sheet (more than 10 mm), so lace openwork from such material is unlikely to be obtained. As an option, a main canvas made of thick sheets and carved inserts to increase decorativeness.

Portal member temernik, who opened a topic that is still active to this day back in 2011, uses sheets different thicknesses, depending on the purpose of the items.

temernik FORUMHOUSE Member

For my father's anniversary, I cut out a carved frame from 4 mm plywood, and a stand for flower pot, on the bears, sheets 8 mm thick were used.

Tools, templates, assembly

Patterns on plywood are cut out using jigsaws - this can be done either manually or electric tool. For complex, openwork elements, a manual jigsaw with replaceable files is often used. They can accurately cut out the most intricate patterns, while a jigsaw is more likely to ruin the design if the skills are insufficient.

Even in labor lessons, they teach that the quality of the saw and ease of use largely depend on the tension of the file - with a loose set it is more difficult to make a cut exactly according to the template.

Temernik uses his son’s old jigsaw, left over from his school days. This simple tool is enough for him to create his plywood openwork.

To start cutting out a design, a puncture is made on the blank with a sharp awl, into which a file is then inserted; the second option is to drill with a drill with a thin drill bit. In both cases, it is not recommended to bring the hole directly to the contour line, if the motive allows. Puncture or drilling at a distance will help avoid possible cracks and “cuts”. To process the edges of cuts (ribs), files or sandpaper with the appropriate grain are used; this grinding gives the pattern a finished look and removes minor flaws, leveling the edge. In addition to the basic tools, you may need pliers, a hammer, a drawing set (ruler, compass) and others.

Even simple drawing it is cut out according to a template applied to plywood - if you have artistic talent, the patterns for sawing are drawn “from your head”; if nature is not so generous, they are transferred from a stencil.

There are enough standard preparations on the Internet in free access, in thematic publications. In a thread on the forum, many craftsmen share their favorite templates with each other. Temernik The Internet and my wife’s drawing talent help.

temernik

I take drawings from the Internet, then I come up with a method of fastening and modify it; if something is wrong, then my other half completes the drawing, she does it well.

The design is transferred from the stencil to the plywood with a pencil or pen; for convenience, the base is secured to the sheet with buttons. Special attention is given to small contours; a few inaccuracies can spoil the entire appearance of the finished product.

To increase decorativeness, products cut from plywood are joined into a tongue-and-groove pattern and glued, most often with PVA glue for wood. First, dry “fitting” is carried out, and after adjustment and cleaning, the adhesive assembly is completed.

temernik

Everything is attached in the following way: some parts have grooves cut out, others, on the contrary, have protrusions, everything is first fitted “dry”, and then assembled with PVA glue. The ends were sanded.

After assembly, the plywood is covered with protective and decorative compounds - varnishes, stains, paints, depending on the desired effect.

Examples of work by portal participants

Open temernik The topic received a lot of responses, many shared their creativity in it.

Bosun1955 I started with a similar technique.

And now he combines it with equally interesting, multi-layer cutting.

Boatswain1955 FORUMHOUSE Member

I finally understood the essence of sawing out plates various shapes– two drawings of the same size are made, the waves are drawn in opposition to each other. That is, where on the first there is a ridge, on the second there is a trough. After cutting, the parts are assembled one at a time. This makes two plates. Sawing with a hand jigsaw without any fancy, for a long time I could not figure out how such forms were made. So I took my soul away a little, sawed some plates and a basket.

56Vladimir1981 He is also a master at using a jigsaw.

First of all, you need to properly organize working space. Despite the apparent formality, this is a very important condition. A properly equipped place provides not only comfort and convenience, which is important when working for many hours with a hand jigsaw, but also directly affects the quality of the project being implemented.

A special machine-table is used as a thrust structure, behind which the name “dovetail” is assigned. It represents a small rectangular board, having a wedge-shaped cutout that goes into the working field for sawing. The dovetail is attached to the edge of a table or workbench using a clamp.

They work with a hand jigsaw while sitting or standing, placing the workpiece for cutting at a level of 30-40 cm from the eyes. The light source is placed in front at an angle to the working plane. Compliance with these rules will allow you to control the cutting line as accurately as possible, thereby improving the quality of the cut project.

Which jigsaw should you choose?

Despite the simplicity of their design, modern manual jigsaws have a number of features that you should pay attention to when choosing. It is better to avoid models with a frame made of sheet iron and choose a jigsaw made from a metal tube. This option provides better tension on the blade and eliminates its distortion, so the file will not “lead” during operation.

The file is fixed in the frame by tightening the upper and lower wing nuts. When choosing a jigsaw, pay attention that it is equipped with blades made of high-quality steel with wide ears. This will significantly increase the ease of use of the tool during work.

How to properly prepare a tool for use?

The file in the jigsaw is fixed strictly vertically, with the teeth down. The canvas must be stretched. The degree of tension is regulated by compressing the frame: the tool is rested against the edge of the table or squeezed by hand, after which the wings are tightened, if necessary, tightening them with pliers. By straightening, the frame will ensure proper tension on the canvas.

For sawing with a hand jigsaw small parts, figures with sharp contours and complex wood patterns use small saws with a large number of teeth per inch. They do not jam when turning, creating a thin and neat cut without leaving chips. To create large plywood products and long straight cuts, blades with large teeth are used, which cut much faster.

Let's get down to business. How to cut out plywood and wood with a jigsaw?

To get an accurate and neat cutting line, you should follow a number of basic rules:

- The hand with the jigsaw should only perform vertical movements.

- Up and down movements are made without sudden jerks and with maximum amplitude in order to use the entire working length of the blade.

- The second hand smoothly turns and moves the workpiece during the sawing process.

- There is no need to press the file onto the workpiece or apply lateral pressure to the blade.

- Sawing occurs only at the moment when the file moves from top to bottom, so the reverse movement should be performed freely without pressure.

When working with a hand jigsaw, it is guided not along the line of the pattern, but along inside contour, since even the thinnest blade leaves a cut, the width of which should be taken into account. This is especially important when cutting out products with precise fitting of elements, for example, or.

When you're done, don't forget to loosen one of the clamps so that the jigsaw frame doesn't lose its elasticity.

What about practicing basic techniques?

The most intricate patterns are always based on a number of basic shapes and elements, after working on which you will be prepared to carry out complex projects. It is advisable to do this on thin plywood up to 3 mm thick.

Obtuse and right angles : the jigsaw moves smoothly without pressing on the workpiece, as if idling; at this time, the second hand slowly turns the wooden piece to the desired angle.

Inner circular outline : to do this, a small hole is drilled in the inside of the figure through which a file is passed. When cutting out a circle, the cutting line is drawn along the inner contour of the design. The stroke of the tool should be of medium intensity; the workpiece unfolds in proportion to the movements of the jigsaw.

Oval outline : when cutting out such a figure, increase the stroke of the jigsaw in steep areas, turning the workpiece faster in this place.

Sharp corners: a neat sharp angle without chips or other defects is obtained by bringing two cuts together.

Advice! When sawing out complex openwork patterns, start working from the center of the wooden workpiece, evenly moving towards the periphery. This will significantly simplify the cutting process and avoid breakage of the fragile work at the finishing stage.

You have gotten a good feel for the jigsaw, have achieved smooth movement and are maintaining a neat cutting line, but then the movement of the tool becomes difficult and the file jams in the workpiece. This is a typical situation that arises when carving plywood with a hand jigsaw. It happens for the following reasons:

- Overheating of the file - during prolonged use, the blade expands due to heating. To avoid similar situations take short breaks or periodically wipe the canvas with a damp cloth.

- Features of wooden blanks. The movement of the jigsaw may be difficult due to the fact that the file has run into a denser area: a knot, a lump of glue in plywood, etc.

- On long cuts, the saw blade can become pinched between two nearly separated pieces of plywood. You can continue sawing comfortably by pinning the separated ends together with a clothespin.

What kind of plywood is needed for cutting with a jigsaw?

Practice shows that best material for working with a hand jigsaw - birch plywood with a thickness of 2 to 8 mm. It is affordable, easy to use and highly durable.

To create small details or a “dense” openwork pattern, it is more appropriate to use three-layer plywood up to 3 mm thick. It is easy to saw and at the same time quite durable. The likelihood that you will spoil the sawn curl when the blade jams again is significantly lower.

When choosing material for crafts, pay attention to the fact that the plywood is smooth and without large quantity knots. Examine the end for the presence of air chambers; their presence indicates uneven application of the glue. It is better to refuse such low-grade plywood, otherwise you will not avoid a large number of chips that will ruin appearance products.

What if you use wooden blanks?

For all its practicality, plywood does not have such an expressive texture as board. By sawing projects from planks, you can take advantage of these advantages: play on the difference in colors and shades, the orientation of wood fibers (as in intarsia), etc. Crafts made from wood have a more attractive end (without a layered structure like plywood) and are much easier to treat with a finishing compound.

For sawing with a hand jigsaw, workpieces from soft and hard rocks up to 10 mm thick are used. When choosing a material, give preference to tangential cut boards. It is not recommended to use radial cut workpieces, because... they have parallel located tree rings, which, due to their hardness, will lead the jigsaw away when sawing.

What to do if chips keep appearing?

The number and size of chips depend on the type of plywood used, the quality of the blade and how correctly the master saws. A few tips and professional tricks will help you cut with a hand jigsaw without chipping:

- using low-quality plywood that is prone to chipping, saw more intensively, installing blades with fine teeth;

- use a saw blade with a reverse (reverse) tooth, designed to minimize chipping.

- glue the cut lines on the back side with tape or masking tape;

- moisten the back of the workpiece.

How to transfer a diagram to a wooden piece?

There are several convenient options transferring the printed drawing onto a wooden base:

- using carbon paper and redrawing the template by hand;

- gluing the sheet with double-sided tape;

- gluing the picture onto glue, the remnants of which are rubbed off with sandpaper at the finishing stage.

Patterned cutting of plywood is one of the most beautiful works of art, which contains grace and lightness. At the same time, in order to translate your ideas into a finished product, you practically do not need to resort to any expensive equipment - in most cases, having a jigsaw and the desire to create is quite enough. With the right approach, acquiring initial skills is not as complicated a procedure as it might seem at first glance.

The main role in the process of cutting patterns from plywood is played by the ability to use a jigsaw, as well as the properties of the material used. Also, a lot depends on how well the drawings for cutting out of plywood are copied - only through a correctly transferred sketch can you turn an ordinary sheet of plywood into a real work of art.

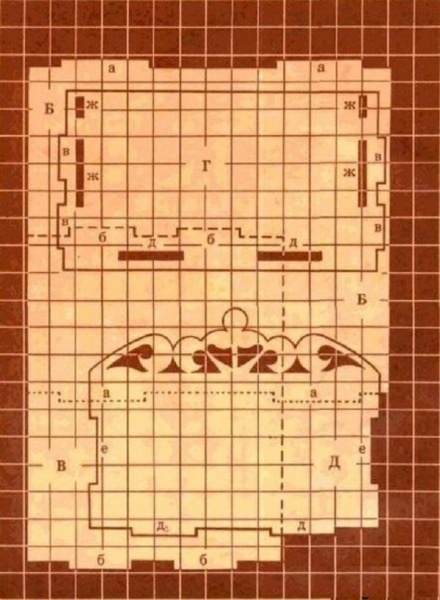

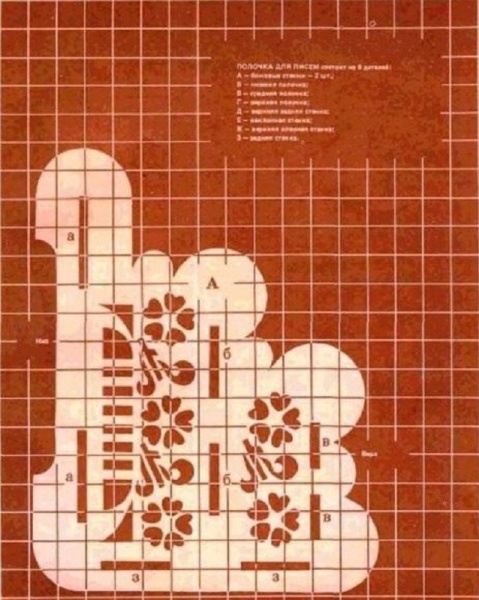

Sides - drawings for cutting out a box from plywood with a jigsaw

Sides - drawings for cutting out a box from plywood with a jigsaw This article will provide you with detailed instructions about how to learn how to cut out basic shapes from plywood with your own hands. Once you've mastered cutting simple drawing lines, you'll understand the basic principles this process— in the future you will not have any difficulties mastering the next levels of mastery. It will also describe the most common methods of transferring drawings to workpieces.

Basic shape cutting skills

There is also an electric modification of the jigsaw, which runs on a 220W network - its use is also acceptable, which significantly speeds up the cutting process. However, the increased weight of the tool makes it more difficult to cut smooth lines, which can be a serious drawback for a non-professional - if you are learning the basics from scratch, then it is much more convenient to use a manual analogue.

Body positioning

The most optimal position for cutting is a sitting position - cutting while standing is quite tiring. The workbench (work table) should be low enough so that you can sit with a straight back.

To reduce the load on working hand her elbow can be placed on her knee - this way she will get less tired. Ideally - workplace must be fully adapted to the above requirements.

Tool

To implement figure cutting you will need:

- Jigsaw complete with file– the main tool for cutting;

- Awl or drill with a fine tip– to create initial holes;

- Set of files, needle files and sandpaper– for processing edges;

Basic moments

Before you seriously think about the question: what can you cut out of plywood with a jigsaw? — you should pay attention to the main features of this process, failure to comply with which can lead to damage to the tool and uneven cuts.

- The position of the jigsaw must be strictly vertical - the sawing movements must be carried out up and down. Even a slight tilt of the jigsaw will make the cut oblique and the file will “lead”;

- The sawing movement should be carried out smoothly, without excessive force and pressure - this can damage the file and cause it to break;

- When cutting internal contours Using an awl or drill, an initial hole is created into which the file is installed and only after that it is fixed. When positioned correctly, the teeth should face toward the bottom of the holder;

- The file must be well secured and tensioned - this is a prerequisite for the normal operation of a manual jigsaw. If the blade is not tensioned enough, the cut will have a wavy structure, which will make the work impossible;

- Vibrating the plywood during the cutting process is unacceptable - this will lead to chips and breakage of the blade. If the sheet is thin and small in size, you must use wooden block with a cut that is fixed on the workbench;

- As the teeth of the blade cut through the wood, the sheet of plywood should be moved towards the jigsaw. The jigsaw must be kept in a strictly vertical position throughout the entire cutting process.

Sawing simple shapes

Smooth lines

There is no need to apply additional effort or create pressure - continue to saw smoothly, returning the jigsaw to a vertical position until the blade levels itself.

Acute and obtuse angles

Obtuse corners - drawings for beginners for cutting out plywood with a jigsaw

Obtuse corners - drawings for beginners for cutting out plywood with a jigsaw To cut obtuse corners, you need to master the “turn on the spot” technique - after cutting to the corner, stop moving the plywood and start turning it, without ceasing to cut, until you reach the required degree. You can cut sharp corners in the same way, but in some cases this is not possible - in this case, the method described below is used.

One of the sides of the angle is formed, then a small loop is cut along the outer contour of the line, through which an acute angle is formed as in the figure below.

Internal corners cut out like this:

- A hole is made with an awl or drill - the cut begins from there, which continues to the top of the corner.

- Then the blade returns along the cut to its original position.

- After which a small hole is cut out, in which the file is turned to form the second side of the corner.

Plywood drawings for cutting with a jigsaw - sharp corners

Plywood drawings for cutting with a jigsaw - sharp corners Transferring a drawing

Almost all patterns are transferred to plywood from a paper sketch - in most cases this process cannot be avoided. The cheapest option is to use tracing paper - with its help, the drawing is transferred from the paper to the workpiece.

Its price is quite affordable, but the process itself is quite labor-intensive, since each line has to be traced with your own hands.

A less labor-intensive way to transfer drawings for cutting out plywood with a jigsaw is to use a projector, through which the image will be projected onto the workpiece. This option is also suitable for cases where the original image size is not large enough and cannot be transferred without first enlarging it.

Note!

Although this method takes place in modern practice, is obsolete.

One of the most modern options is the use of self-adhesive sheets of paper, onto which the desired sketch is applied using a printer, after which they are glued to the workpiece.

The paper adheres quite tightly to the plywood, and its presence has practically no effect on the cutting process. The only disadvantage of this method is the relatively high cost.

Bottom line

Our guide will help you master the basics of this skill, which will later allow you to move on to more professional level. In the video presented in this article you will find Additional information on this topic.

Similar materials

From carved wood and plywood you can make so many decorative items and useful little things that it is stupid to limit the scope of the work. In fact, it can be absolutely anything that your imagination can handle: boxes, covers for decorative and collectible books, lampshades, panels, shutters, furniture elements, trim, cornices... But the most attractive thing about creating exclusive works is that anyone can do them willing, if he puts in a certain amount of effort.

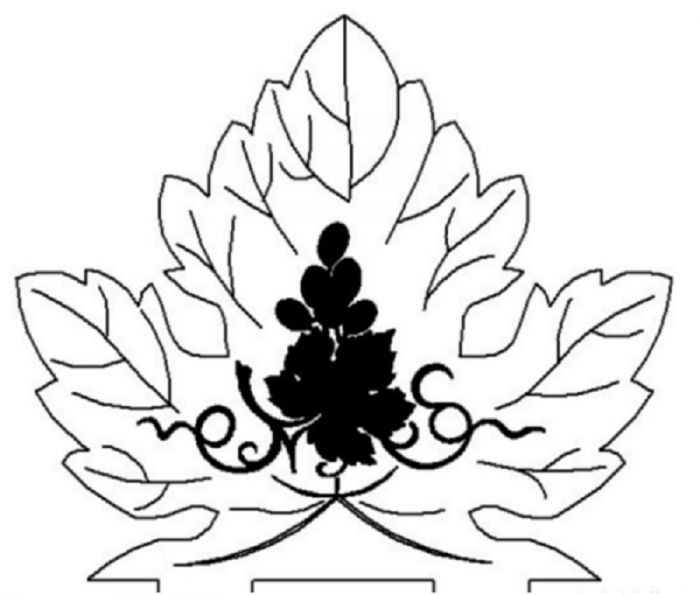

Wood carving: photographs, drawings and sketches

The main key to success in creating interesting things with slotted carvings is the choice of pattern. It is he who conveys the overall concept and sets the aesthetic tone for the entire product.

The easiest way for beginners to make patterns geometric shape as in the photo.

Carved designs of floral and animal themes are classic ornaments for any field of application.

Inscriptions are a modern version of the use of wood and plywood carvings. At the same time, you are unlikely to be able to find drawings and sketches on the Internet - they will have to be compiled purely individually according to personal requirements for sizes, fonts, and words.

Stencils for slotted threads

However, unlike cut-out inscriptions on plywood, drawings with plant, animal and fantasy themes can be found on the Internet. So feel free to choose the stencils you like for your album, and you’ll have plenty of ideas for creativity for a long time!

The most simple sketches are suitable both for training at the very beginning of the process of making products, and can also become separate elements complex design. For example, this is how carved houses are decorated.

More complex templates will require some skill and patience, but the results are worth it. Such pictures can serve as an independent product, even as a gift.

Entire compositions with an idea and meaning usually serve either as a separate work or form the basis of a work.

Tools for slotted carving: jigsaw or router

However, choosing a design is only a third of the success. Another important aspect, which must be considered before starting the work itself. Namely, the choice of tool that will be used to carve wood or plywood.

Depends on the equipment:

- how thin the thread will be;

- complexity of pictures;

- cutting speed;

- accuracy of work.

Therefore, it is important to evaluate all the pros, cons, capabilities and limitations of each of the traditional sawing tools:

A jigsaw is a device for shaped cutting of parts. Hand tools The work is quite labor-intensive, but allows you to very accurately cut according to the drawing. Power tools allow you to quickly produce shaped plywood products, but require caution.

A milling cutter is a tool thanks to which flat-relief slotted threads acquire a thinner and more complete appearance. It is with its help that you can round edges, remove chips, make valances, and carry out the most complex cutting.

Theoretically, a milling cutter can do the same work as a jigsaw, and even more, but in fact, such handling of the tool is fraught with its rapid failure and frequent replacement of the frieze.

Materials for slotting threads

In most cases, plywood is chosen for this type of work - it is uniformly thin, has a pleasant color and structure, and does not suffer from further use or storage, unlike solid wood. It is the choice of material that becomes the third pillar of successful work.

The modern market is abundant different types materials, so it’s easy to get confused. For this work you should choose:

- FC plywood - harmless to humans and the environment, durable, easy to cut, practical;

- FB plywood - also safe for humans, but resistant to aggressive environment, since it undergoes special processing and receives protective covering, because of which it may cost an order of magnitude more.

Note! Do not under any circumstances choose to interior work FSF class plywood - it is treated with carcinogenic preservatives and is permissible for use only in the fresh air - they are excellent for lining a bathhouse or a house outside.

Photos of carved wooden houses

For Russia, slotted carving is of particular importance as a decoration for building facades. Since ancient times, ornaments carved on birch bark and other similar materials have been decorating huts, bathhouses, and churches, as photographs colorfully demonstrate.

Video of wood milling with a hand router

If you have just decided to try your hand at curly slotted carving, it would be a good idea to watch a video with a master class. It will help you better understand how drawings are created and how such home beauty appears.

Crafts made by craftsmen with a jigsaw look elegant and stylish. In capable hands ordinary tool turns into a miracle jigsaw, with the help of which incredible masterpieces are created. Artistic sawing can be just a hobby or a professional activity, because the products self made are always appreciated. The features of the miracle jigsaw and the procedure for performing interesting crafts will be discussed further.

Characteristic features of a jigsaw

The miracle jigsaw provides convenient cutting of lines on wooden base, this is facilitated by a narrow cutting blade. More useful for woodworking band-saw, but cutting out plywood is a better miracle with a jigsaw. The main advantages of the tool are as follows:

- Accurate cutting of parts, the cut line comes out quite smooth and does not require grinding.

- Thanks to the narrow blade in the miracle jigsaw, cutting out sharp corners and small parts is possible.

- Processing of internal grooves begins with a hole prepared with drill number 3.

Regarding the technical characteristics of the miracle jigsaw, the following features are noted:

- Easy stretching and fixing of the fabric.

- The cutting process is much easier than with a band saw.

- Cutting out a miracle with a jigsaw creates virtually no risk of injury.

- The tool does not require frequent adjustment.

There are several parameters that you should focus on when choosing a miracle jigsaw for cutting:

- The main thing is capacity, this indicator indicates the size between the back wall and cutting blade. There are miracle jigsaws with sizes from 12 to 26 inches.

- The thickness of the material that the tool can process.

- Number of moves in 1 minute.

- Saw stroke height.

To cut complex elements from plywood using a miracle jigsaw, two types of saws made of steel are used.

Advice! For beginners, it is better to practice on a large-toothed blade designed for thick plywood. It is also used to make cutting boards. Small teeth on a thin file allow you to cut out filigree elements of crafts from thin plywood.

The result of the work of a top-class professional is presented in the photo:

Preparatory steps

Sawing out a miracle with a jigsaw requires painstaking work from the master and develops perseverance and patience. Initially, you should take care of organizing your workplace. Prerequisites for comfortable work - high-quality ventilation and lighting. A private house provides more possibilities choice utility room, in the city suitable for apartment glazed balcony.

Second important stage is the purchase of material. High-quality plywood reduces the risk of part delamination or cracks appearing when cutting out a miracle with a jigsaw. The second reason for violating the integrity of the material is an incorrectly selected canvas or unprofessional actions. For cutting crafts, plywood with a thickness of 3-4 mm is intended. The following steps will help prevent delamination:

- Depending on the area of the surface to be treated, dilute the required volume of the mixture of water and PVA glue. For small areas, 2 tablespoons of water and a few drops of glue are enough.

- After thorough stirring, the solution is applied with a brush to back wall plywood blanks in 2-3 layers.

- The material is left until completely dry.

Comment! Glue solution will successfully replace furniture or parquet varnish.

Before cutting out the miracle with a jigsaw, the plywood needs to be cleaned. Chips, microscopic cracks, dark marks from knots are removed with sandpaper of various grain sizes. To give the surface maximum smoothness, stripping the plywood against the grain helps. First, work with medium-grain paper, finishing touches Apply with fine-grained sandpaper. The complete absence of burrs allows you to move on to the main stages of work.

A simple example of a craft for beginners is presented below:

The process of creating crafts

Preparing a drawing, cutting out a miracle with a jigsaw, assembling parts and decorative finishing- key steps to create original crafts.

Translation of the drawing

A well-executed drawing will ensure quick assembly of finished elements into a single figure. Otherwise, after painstaking work with a jigsaw miracle, there is a risk of encountering the problem of misaligned grooves and the need to remake individual parts. You can take drawings of crafts from this article or try to create a unique sample for cutting. After printing or drawing on paper, the drawing is transferred to plywood using one of the convenient methods. In the first case, the drawing is secured with buttons on plywood and copied using a pen and ruler.

To cut out crafts with a miracle jigsaw, the technology of thermal transfer of toner from paper to plywood can be useful:

- Select a material with a low toner retention rate (like glossy paper).

- In the printer settings, high-quality printing is selected to get more toner. In this case, the procedure for cutting out a miracle with a jigsaw is easier.

- The printed image is attached front side to plywood and ironed. For A4 format one minute is enough. Instead of an iron, a hair dryer is suitable.

- After the paper has cooled, it is removed. If there are gaps in the outline of the sketch for cutting out a miracle with a jigsaw, they are completed with a pencil.

Making holes and sawing

Cutting out the internal grooves with a miracle jigsaw is preceded by the design of the holes. The process includes the following steps:

- Prepare a drill with a drill diameter of 3 mm or an awl of appropriate sizes.

- The tool is placed in the middle of the groove and a hole is made.

- It is recommended to first protect the desktop with a board.

- Having an assistant is welcome.

To make a miracle with a jigsaw into internal grooves, a nail file is inserted into the hole and secured in the upper part of the tool. After processing small area about 2 cm check the evenness of the cutting. If the cut is of poor quality, it is better to replace the blade with a more suitable specimen. If the cut is not smooth enough, try correcting the imperfections with a flat file.

Important! Follow safety standards and do not let your fingers get caught in the file.

Cleaning parts

Upon completion of cutting out the miracle with a jigsaw, small chips on back side parts are cleaned with sandpaper. Also, the prepared craft elements need polishing. The ribs and back of the parts are first treated with medium-grain paper, and at the final stage fine-grained sandpaper is used. It is convenient to clean the internal grooves cut using a miracle jigsaw with a rounded file. Strive for a complete absence of irregularities and burrs at the end of sawing.

Having achieved the desired result, they proceed to assembling the parts of the craft, prepared with a miracle jigsaw. Interesting drawing for cutting and photos of the shelves are presented below:

The final stage

After assembling and adjusting all the parts, the crafts proceed to gluing using PVA or Titan glue. Depending on the design, it is recommended to tie multi-layer elements tightly with strong thread and leave to dry. The process lasts no more than 15 minutes. An example of a product that is difficult to cut out with a jigsaw is shown below in the photos and drawings:

You can add decorativeness by burning patterns on individual elements of the craft. First, the drawing is applied with a pencil, after which they work with an electric burner. An openwork vase for sweets will become worthy decoration table:

Sawing out a miracle with a jigsaw is a painstaking task. In order for the product to last for a long time, it needs decorative processing. Preservation of pristine beauty natural material varnish on wood helps. For work you will need high-quality composition varnish and a convenient glue brush. Try to ensure that there are no scratches or visible marks on the craft. When cutting out animal figures or models of mechanisms with a miracle jigsaw, sometimes they resort to fragmentary coating of the product with paints. This technique brings the craft closer to the original.