Wood processing has been carried out for several centuries. Since ancient times, rounded logs have been used to build houses, bathhouses and other structures. Giving process correct form processing of logs is quite complex and requires the use of special rounding machines. Create rounding machine Many people who work with logs quite often decide with their own hands. Manual method It is almost impossible to carry out high-quality processing, and it requires quite a lot of time. Let's look at the features of how to make a cylinder machine with your own hands, what types of such equipment there are and many other points.

Equipment use

Modern machines make it possible to carry out rounding so that the prepared log is suitable for installation in wall structures without finishing. The functionality can vary significantly, depending on the design features of the rounding machine and its cost.

When considering all drawings and models of equipment that is used for rounding logs, attention should be paid to the following points:

- Creation of grooves that can be used during installation to solve various problems.

- Production edged boards, parquet, dies.

- Carrying out cylindering work, including final stage the problem under consideration.

- Milling the surface of wood to achieve the desired roughness.

- Creating a crown cup.

- Production of gun carriages by cutting wood.

- Creating an expansion groove using the installed circular saw.

One should take into account the fact that a self-made cylindrical machine may not have all the functions, since for this you need to use complex projects. The easiest way is to create non-universal equipment that is designed to solve specific tasks, for example, rounding of workpieces.

Features of modern industrial models

The main feature of machine models produced by well-known manufacturers today is the use of a laser pointer to control the movement of the carriage. This moment determines high accuracy processing and the ability to carry out the entire process without reinstalling the workpiece. Thus, a CNC-controlled carriage with a set of tools moves along guides and performs various types of operations.

As practice shows, you can make a model with your own hands that will have manual control and the ability to process workpieces up to 7 meters long.

Features of the design of the design in question

When considering what kind of homemade rounding machine drawings may have, we note that often the design has the following elements in one form or another of their implementation:

- The main and most cumbersome element is the frame. It is on it that stress is concentrated and all other elements are attached. When making the frame, it is recommended to use rectangular pipes. The connection of all elements is often carried out by welding, which allows you to speed up work and create a truly robust construction. However, it is possible to create a frame using a combination of a bolt and a nut. Collapsible frames are more mobile, but have less rigidity.

- Guides along which the sawing power and sawing device will move. The length of the logs can reach several meters and weigh tens of kilograms. In order to significantly simplify the processing task, you should create a homemade rounding machine on which the tool moves, and not the workpiece.

- Pasterns: front and back, in some cases, only one. They are necessary to twist the logs during processing. Note that the front one quite often has a dividing head and a workpiece fastening system. Using the dividing head, you can set the rotation angle at each stage of processing, which is necessary to improve the quality of the workpiece.

- As a rule, a milling cutter is used as a cutting tool. There is enough large species this cutting tool. When considering how to make a cutter with your own hands, we note that the work is complex and involves the use of rolled tool steel, which has increased strength and a low degree of machinability.

- A high-quality cutter has replaceable knives that can be sharpened and replaced if necessary. The cutter itself does not wear out over time.

- To properly place a log that has heavy weight, special levers are installed.

- The rollers, acting as a stop, do not allow the log to sag during processing, thereby significantly increasing the quality of the resulting material.

- Almost all models have mechanical brakes that are installed on both sides of the carriage. They are necessary to perform the work of selecting the crown bowl.

- A device that allows you to rotate the steel manually at the time of cutting a longitudinal groove.

Principle of operation

These elements have many drawings that you can use to create a rounding machine with your own hands at home. However, the design can be significantly simplified by taking into account the problems for which it is being created.

Creating a homemade machine

The do-it-yourself scheme for creating the machine in question involves using a sawmill as a base. When carrying out work, a stop will be installed instead of a front stop, and a handle or motor will be installed to rotate the workpiece.

It is quite difficult to create your own cutting tool - a prefabricated cutter. As a rule, it is made by joining several parts from a durable material. A rail is installed to move the cutter.

Processing sequence

When planning to install equipment, it is worth remembering that the final weight of the structure itself and the workpiece can reach several hundred kilograms. That is why the machine should be installed exclusively on a concrete base or tightly compacted soil, on which a thick and durable beam is laid.

Factory model

A do-it-yourself rounding machine will not have the high precision and versatility of industrial versions, but it will still be sufficient to solve a large number of everyday problems. The build process is as follows:

- First you need to assemble the frame. For this you will need building level, since the error should not exceed 0.5 mm per meter. When assembling, rectangular steel beams and, less commonly, pipes are most often used. They can be connected by welding or a dismountable fastener, or combined to simplify the process of reinstalling the machine.

- The next step is to install the power units and headstocks. The importance should be taken into account the right choice electric motor. Previously, only three-phase versions were suitable for this case, but modern options It has also become possible to use versions of two-phase motors (however, their cost is quite high).

- We pay attention to the correct and reliable fastening of the power cable. If possible, it is protected from mechanical impact.

- The installed power mechanism can be equipped with a stopper.

- Grounding is carried out. This point also needs to be paid attention, since metal structure acts as a conductor, and if the power cable of the electric motor is slightly damaged, the current can flow to the frame.

- When installing a three-phase electric motor to rotate a log, it should be taken into account that the arrangement of the phases determines the direction of movement of the output spindle. When changing phases, you can also change the direction of rotation. It is worth remembering safety precautions when working with electricity, especially in the case of a three-phase network with a voltage of 380 V.

When attaching the headstocks, pay attention to the reliability of the connection. In this case, their axes must coincide, since otherwise a rounded beam using such a machine will have a large error in size, and beating may occur during operation. Special attention paid attention to balancing the cutter - an unbalanced cutter leads to rapid wear of the entire rounding machine. The final stage The installation of the cutter, which must be attached very securely, requires the presence of a safety element.

You may also be interested in the following articles:

DIY metal lathe How to make a grinder with your own hands DIY thicknesser machine

It so happened historically that since ancient times people have built their homes from wood. This is quite easy to explain by the ease of processing, the availability of such material and excellent thermal conductivity properties. Many years later, with the advent of new technologies, wood began to be processed using special machines. To obtain rounded logs of the same diameter and length, a special woodworking machine is used for rounding logs.

Features of the rounding machine

The rounding machine is a woodworking machine that is designed for the production of rounded logs and profiled timber from round timber and for the manufacture of log houses. The rounding machine makes it possible to perform all the operations that are provided for by the log production technology: making a selection of mounting grooves, a crown cup, rounding a log (primary and secondary processing) and milling a smooth surface.

You can also use the machine to perform such operations as sawing a carriage into edged boards, sawing a log into a carriage and a board, making moldings and blanks for end parquet, obtaining an edged board from an unedged one.

When using a saw unit without removing the log from the center, you can make a compensation groove to relieve the internal stress that occurs when drying the log. All these operations are performed on the machine sequentially with one set of tools for one installation of the log. Because of this, during production finished log there is no need to reinstall the cutters and log.

The combination of different processing modes makes it possible to obtain products that are quite complex configuration- balusters, timber complex profile and with different diameters. The formed geometric profile allows the construction of wood structures of any complexity. In addition, machines for rounding logs help to process material 7 meters long.

Design of a log rounding machine

The rounding machine includes the following blocks: a common metal frame made of square pipes, on which guides are installed that are intended to move the power unit and the saw carriage along them. On the common frame there are also headstocks and tailstocks, which are needed for installation in the centers of the original workpiece and driving the log into rotation. On the headstock there is a dividing head, which serves to fix the log in different positions, as well as a spindle head for rotating the cutters.

Milling cutters are used as a working tool special design- figured and universal, which are installed on the spindle shaft of the machine. A universal cutter is necessary for rounding, plane milling and cutting out crown cups. The shaped cutter is intended for cutting out the mounting groove. Technological feature The purpose of the cutter used on the machine is to provide a “soft entry” into the processed wood surface. This results in reduced vibration and will also increase the accuracy of the work.

The knives used in the cutters are removable. If the operator saw that it could not be maintained required size treated surfaces, then you need to sharpen the removable knives. Removable knives are made from tool high quality steel, which makes it possible to use one set of them for a long time, and at the same time the resource of the cutter itself is not limited.

To reduce time and facilitate installation, special mechanical levers are used in the center of the log; they can be installed on the frame in any place, as shown in the photo of the log rounding machine. When passing through small diameters (up to 200 millimeters) of the mounting groove, some deflection of the log may be observed; to eliminate this, a stop roller is used, which is adjusted to the diameter being processed and is installed on the side of the logs opposite the cutter.

When choosing a crown cup, reliable fixation of the carriage is required; for this purpose, mechanical brake devices are used, which are placed at both ends of the carriage and securely fixed. There is also a special mechanism for fixing the carriage, which prevents it from rotating when choosing bowls. When making a longitudinal mounting groove or bowl, very precise (manual) adjustment is also required - for these purposes, a special mechanism for manual rotation of the log is installed.

Classification of rounding machines

Log rounding machines can be divided into two types according to technological schemes:

- Pass-through devices with continuous movement of logs. The log in pass-through machines is processed while moving in the tool area without stopping. The movement of logs can be carried out without a gap or with a gap between the ends of adjacent logs.

- Cyclic devices with intermittent movement of logs. During one processing cycle in cycle machines, a repeating set of movements occurs. Cyclic machines are divided in turn into two types:

- Cycle-pass rounding machines: the log is processed cutting tool, which makes working movements;

- Cyclo-positional rounding devices: the log is processed while moving relative to the area of the working tool.

Each combination of movements makes it possible to determine the kinematic cutting pattern using different processing methods. The operation of the machine is represented by the following combinations of movements of the log and the working tool: linear and two rotational, linear and rotational.

A log, when processed in through-flow cylinder cups, undergoes rectilinear movement, and the tool is correspondingly rotational. The log in cyclo-pass machines at the moment of processing along the axis of the log makes a rectilinear movement, and the tool in position is rotary, as shown in the video about the machine for rounding logs. When processing a log in positional lathes, it produces a rotational movement, and the tool itself (cutter) moves in a straight line, parallel to the axis of the log.

Depending on the shape and type of instrument and its cutting edges All types of log processing can be divided into two types - milling and turning. Turning is characterized by a constant process of chip formation. The main movement, which occurs at a fairly high speed when turning, is the rotation of the tool or log. Milling is characterized by a variable chip formation process. When milling, the main movement is the rotation of the tool.

Woodworking machines in our time, according to the degree of automation and mechanization, are divided into the following classes:

- In mechanized machines, the main movement and feed movements are performed without human intervention. The operator provides regulation, adjustment and unloading, as well as loading of the machine.

- In automatic machines (automatic machines), the entire complex of movements and operations is performed by the machine. A person is assigned the role of monitoring the work and periodically loading the machine with workpieces. In fully automatic machines, the loading of workpieces itself is automated.

- In semi-automatic machines, operations are automated only within one cycle, and human intervention is required to complete the next processing cycle.

Comparing different log rounding machines, we can say that not only the price of log rounding machines differs, but also their functions:

- Through-type machines have high productivity, but at the same time they demonstrate low processing accuracy and rather high surface roughness due to the lack of a basing system;

- Cyclic positioning devices guarantee high accuracy and have excellent quality of the processed surface, but their output capacity is much less than through-flow devices;

- Cyclic positioning machines have reliable system based, occupy a fairly small production area and were found in production wide application.

Do-it-yourself installation of a rounding machine

Usually homemade machines for rounding logs, they are made on the basis of a sawmill. The front cone is replaced with a stop, and a thrust bearing or tapered roller bearing is installed on the tailstock. The fixed log rotates using an additional motor, or manually, which is not so practical. Making a cutter is the most difficult. To complete a task as simply as possible, it is made into typesets, that is, assembled from several elements. It should be noted that the material of the cutter itself must be durable, that is, soft alloys are not suitable for these purposes.

Most in a simple way To ensure the movement of the cutter along the log itself, laying an additional rail track along which the installation will move is considered. This will make it possible to eliminate manual dragging. The principle of operation of such an installation is similar to the principle of operation of an ordinary milling machine, when the workpiece, fixed in positions, rotates, and the cutter moves along it.

Remember that it is recommended to install the machine for rounding logs with your own hands on a concrete area. It is also possible to operate the rounding machine on compacted soil. In this case, install the machine on transverse guides of wooden sleepers - for example, a beam with a cross-section of at least 1500X1500 mm. The recommended distance between sleepers is one meter. It is also necessary to prevent soil shrinkage in the places where the machine will be installed.

The machine begins to be installed by assembling the frame. The frame sections should be assembled and installed at an even level in one horizontal plane. Maintain an installation error of no more than 0.5 per 1000 millimeters - both across the guides and along them.

When installing the frame on a concreted area, the frame is mounted at a height of approximately 15-20 centimeters, and the joints of the sections are concreted. The power unit, front and rear headstocks, and racks are mounted on the installed frame, onto which a cable is pulled to secure the electrical moving cable. A clamp-stopper is installed on the power unit. The machine is also grounded to common system grounding.

Next, a motor is connected, which rotates the workpiece. Connect the machine to the electrical network, check that the power supply phases are connected correctly to the appropriate power modes. To do this, press the cutter up/down button. If the actual direction in which the power head moves coincides with the same direction as indicated on the control panel, then the power supply has been connected correctly. Otherwise, it is necessary to change the phases.

After this, you need to check the direction of rotation of the workpiece. When the direction of rotation is incorrect, it is necessary to reverse the phases on the motor. It is prohibited to turn on the workpiece rotation motor and the rounding machine motor until the correct connection of the power supply phases has been checked.

If, after you have made a machine for rounding logs, you carry out the initial start-up more than two months later, after a long break, or the machine was in storage and during transportation in a condition high humidity, then before starting it is necessary to keep it in a dry room for some time to remove moisture from the electrical equipment.

Remember that the front and rear headstocks of the log rounding machine must be placed parallel to the guides and, according to the selected length, be rigidly fixed. In addition, it is necessary to check the alignment of the tailstock and headstock of the rounding machine. For this purpose, measure the distance with an accuracy of one millimeter: between the vertical longitudinal profile and the center of the headstock, between the near guide and the center of the headstock. It is necessary that these distances be the same for the tailstock and the headstock.

Improper balancing of cutters and changes in the sharpening angle of knives can lead to failure of the rounding machine, or to deterioration in the quality of the surface of the product. The shaped cutter is installed on the conical part of the shaft and secured with a bolt. A universal cutter is screwed into the body of the shaped cutter and then tightened with a special wrench.

In addition, if you have made a machine for rounding logs, check that the frame is mounted correctly and horizontally. By placing spacers under the rear headstock, you can determine the parallelism of the axes of the tailstock and front headstock with the plane of movement of the cutter. The thickness of the gasket should be equal to half the taper value.

Rounding machines are the main components of wood processing lines, which are applicable both in standard workshops and in the manufacture of similar products with your own hands. The main function of this machine is due to the cutter with a complex design and different types shoot smooth upper layer from every log.

Currently, there are a huge number of similar products of various types and purposes on sale, among which it is not at all difficult to choose the equipment that is ideal for your case.

1 Galvanizing machine - equipment features

A machine for rounding logs is a mechanism in which the processing of logs is carried out through the contact of several special cutters with them. The latter are driven by a special motor (in some configurations there are two of them).

All logs are securely fixed by the system during feeding, making their simple and uniform processing possible.

Also, depending on the type of equipment, it may also have a rail track, the installation of which for the walk-through version requires a special concrete base for installation.

On sale presented different kinds rounding machines, including equipment of the Rus and Sherwood type, pass-through type, as well as modular type.

This equipment, like Sherwood or Rus devices, can be independent units or be part of a woodworking complex. They come in different capacities.

The average volume of logs that the Rus, Termit, and Sherwood machines can freely pass through is 240 mm, although some versions of such equipment can easily handle larger samples.

Rounding and milling machine Sherwood OF-28Ts

Cylinder installations allow you to perform whole line types of material processing. In particular, it is used to directly round logs, prepare a longitudinal laying groove, a compensation cut, as well as specialized elements for fastening - side bowls.

This is suitable equipment for everyone without exception varieties of material,

including popular beech, oak, birch, ash, pear, alder, pine and other types of wood.

1.1 Pros and cons of this processing technology

The advantages of this type of machines for processing logs include:

- High speed of product processing.

- Precision in many types of processing thanks to the variety of knife sharpening.

- Absolute operator safety when working with such equipment.

- Simplicity in tinctures, high level automation of such devices.

- High quality of material processing, regardless of the quality of the wood processed

- Versatility - with this device you can make any workpiece from natural wood.

- Low wood consumption, which is provided not only by the Rus and Sherwood samples, but also by a homemade rounding machine.

As for the disadvantages inherent in this type of device, among them it should be noted:

- large dimensions of the equipment, due to which those who like to process wood with their own hands cannot always install such structures in their own home;

- high prices for replacement parts, as well as the necessary processing of products before starting work, for example, sharpening knives.

1.2 Replacement parts for rounding machines

For simple processing of logs on such machines various types without changing the finishing quality of the material for such structures It is necessary to purchase the following types of components:

- Replaceable cutters, especially non-standard types (when purchasing these components, special attention should be paid to the quality of sharpening knives for certain types of timber).

- Additional electromechanical drives for some design types.

- Replacement parts for processing bowls.

- Parts for making compensation cuts.

Also, sometimes for this type of equipment, including Sherwood and Rus machines, you can buy special types of knife sharpening for individual logs, as well as some flexible replaceable elements. You can replace them yourself. The list of such for each device is individual.

2 Popular types of rounding machine

Currently, there are several popular varieties of such equipment used by professionals, as well as DIY enthusiasts to carry out construction, repair, Finishing work in the house.

Among these models:

- Rounding machine Altai. The equipment, thanks to its knife sharpening features, allows you to process logs with a diameter of up to 550 mm. Equipped with spherical and end-type cutters. The main advantages of this version when processing logs: the ability to select the optimal speed of the device throughput, as well as adjust the depth of penetration of the knives. Ideal for all types of production, like Sherwood, including the construction of small wooden houses.

- Rounding machine Kedr. Another type of pass-through type equipment For industrial enterprises. Allows you to lay up to 7.5 meters of logs per processing. Suitable for all types of logs thanks to the unique type of sharpening of the cutter.

- Rounding machine Taiga OS 1. The equipment, like Sherwood, is suitable for roughing and finishing types of wood processing. Allows you to work with samples with a maximum diameter of 240 mm. Like other examples of the walk-through type, it can be used for industrial purposes, including the construction of a house or bathhouse from timber. Depending on the type of knife sharpening, it can be used for various tasks.

- Rounding machine Termit. Universal equipment pass-through type, like the Rus machine, suitable for processing various types of timber. Ideal for industrial enterprises where it can receive up to 900 linear meters finished timber per shift. Modern design This equipment eliminates the possibility of the log turning during processing.

All types of this equipment are most suitable for industrial production of timber, however, if there are proper conditions for doing it yourself, they can be used at home.

The cost of such products, as well as the Rus or Sherwood models, depends on the equipment configuration, as well as a company selling this type equipment. The best prices for it from official dealers.

For those for whom such products are not suitable technical parameters, you can make a homemade rounding machine, created according to existing equipment sketches.

2.1 The process of rounding logs on a machine (video)

All photos from the article

The construction of wooden housing in our great power has been developed since ancient times. First of all, this is caused by colossal reserves of this environmentally friendly and relatively inexpensive material. Despite the emergence of many new construction technologies, classic log houses still remain popular. After all, the advantages of rounded logs are obvious, and they will be discussed further.

Why exactly a log?

First, let's find out what a rounded log is and why the vast majority of people prefer to build housing from it.

Important: speaking in the dry language of definitions, a rounded log is usually called a straight tree trunk, pre-processed on woodworking machines to give it the correct cylindrical shape.

As a result, the top uneven layer and knots are removed, and compensation and mounting grooves are applied.

Advantages of the material

- Wood itself has a natural porous structure, making it one of the best warmth and sound insulators.

- Having clear geometric dimensions, this material fits perfectly together. Specially designed grooves ensure high tightness and quality of inter-crown seams.

- All trunks have a clearly fixed diameter, the maximum deviation here can be no more than 2 mm. This makes it possible to choose wood for the construction of premises for various purposes with specified characteristics.

- On this moment there is simply no building material that is more environmentally friendly and beneficial for people. Unlike wood traditional brick or modern views building materials can only boast of environmental neutrality.

- Although the price of rounded logs may be higher than that of many competitors, such houses do not require additional internal and external cladding. This material itself has natural beauty, as a result of which owners save significantly on finishing.

- Modern woodworking equipment makes it possible to initially produce trunks with ready-made connecting elements. This significantly speeds up the construction process and gives a lot of layout options.

- You may have already heard that natural wood breathes. This refers to the array's ability to take out of thin air excess moisture and give it back when conditions change. Simply put, a tree is natural conditioner, providing an ideal microclimate for human life in the house.

- And finally, the construction instructions are quite accessible. A simple bathhouse, a barn or a small country house, a good owner at great desire can build it with his own hands.

What are the disadvantages

- As we have already said, wood is a living material, so over time the wood begins to dry out and crack. This is true, but thanks to modern technologies, such processes can be significantly slowed down.

- Many people know that during the process of growth, a tree trunk slightly twists in a spiral. After the cut, this spiral sometimes begins to unwind. This is why craftsmen do not recommend building from freshly cut timber; the structure may fail. But a dry rounded log does not have this drawback.

- Disadvantages such as high fire hazard and susceptibility to biological pests are easily eliminated using the same specialized impregnations.

- Perhaps the only significant drawback of any wooden structure is a high percentage of shrinkage of new houses. Well-dried, high-quality wood shrinks up to 100 mm for every 3 - 4 m of wall in the first year. And 10 - 20 mm each for another 2 - 3 years. Freshly cut timber will take up to 10 years to shrink.

What affects performance

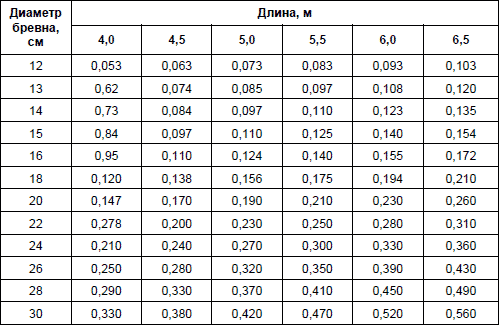

To determine the basic parameters of the material, there is a set of regulations. In our country this is GOST 2708-75, in the west ISO 4480-83. There is no big difference between them, the main parameters are identical. It is on this data that a program such as a calculator for rounded logs of volume, weight, density and other characteristics is based.

Advice: it is desirable that the table of volume of rounded logs be original, that is, taken from the above-mentioned regulatory documents.

Since now there are many corporate tables compiled taking into account the commercial interests of some corporations and containing inaccuracies that are beneficial specifically for those who compiled them.

Machines and equipment

Even 50 - 100 years ago, every carpenter or just a good owner knew how to round a log at home. Due to the fact that this occupation is long and very labor-intensive, with the development of woodworking production there are not many real specialists left.

Of course, in the debate about whether a log or a rounded log is cheaper, an ordinary unprocessed trunk wins. But line up good house or quality sauna from “wild” material is almost impossible. Apart from the time spent on handicraft cylindering and labor-intensive installation, you will not be able to seal the seams and joints hermetically. Accordingly, the room will be cold and will not last long.

A machine for cylindering logs is, in fact, a symbiosis of milling and turning functions. Such equipment has impressive dimensions and includes a common metal frame on which they are based, a power unit, which can consist of several power units.

The main work is done by the headstock. It is on it that cutters for stripping the top layer and figured cutters for finishing the log are installed. Tailstock, as in most similar equipment, serves to fix and feed the workpiece itself.

If you want to know how long it takes to make a rounded log, then in this case it depends on the quality and functionality of the equipment. Modern automated lines are capable of turning a high-quality calibrated product from natural logs in a matter of minutes, according to specified parameters.

All such units come in two types – continuous and cyclic. The first ones are designed for large production volumes and have a minimum of functions. In them, the material moves in a continuous flow and, passing through work area, cylindered and milled.

People have worked with wood for a very long time. Since then, the use of this raw material has only gained momentum. Currently, there are entire facilities dedicated to wood processing. However, skillful owners can assemble some devices themselves if they need to large quantities process wood. Enough useful device became a rounding machine.

Purpose of the equipment

The main purpose of this machine is that it is used to give the correct shape to those logs that are used for the construction of log houses. Naturally, harvesting can be done manually, but the use of an automated device significantly speeds up and facilitates the entire process.

The rounding machine has next row functions:

- prepares grooves in logs for further installation;

- carries out rounding of the material;

- used for the production of edged boards from carriages;

- you can prepare dies for parquet;

- smooth wood can be milled;

- pruning unedged boards;

- production of timber of the required dimensions.

In addition, this equipment can create expansion grooves using a circular saw, and the processing speed of raw materials is adjustable.

What does the unit consist of?

The rounding machine includes several of the following components:

- Metal frame, which is most often made from rolled pipe rectangular type.

- Necessary guides for moving the power and sawing device.

- Headstocks used for fastening and torsion of logs. The headstock must be equipped with something that secures the barrel. The spindle head will also be mounted there.

- The milling cutter for rounding machines is one of the key elements. If the cutter is of a figured type, then it can be used to make a groove for mounting, but if it is universal, then it can be used for rounding, cutting crown cups, and processing planes.

- An important element There will also be removable knives for the cutter. They must be made of good steel. The main convenience is that they can be replaced without removing the cutter itself.

Types of units

Today there are several types of rounding machines.

Pass-through type machines ensure constant movement of the workpiece on the table, processing it at the same time. There are also cyclic type machines, in which movement and processing occurs in several cycles. In addition, this one is divided into two more - these are cyclo-pass and cyclo-positional. In the first case, the wood workpiece remains stationary, and the cutter moves; in the second case, on the contrary, the processing tool does not move, the wood moves.

It is also worth noting here that the division of machines is also carried out according to the level of their automation. There are mechanical, automatic and semi-automatic machines. If a mechanical type of machine is used, then loading of material and setting up all processes is carried out by the operator. IN automatic machines all this happens without human intervention, you just need to control the progress of the work. Semi-automatic machines are capable of controlling only one stage of work; then operator intervention will be required.

A small comparison of classes

Continuous-type rounding machines are distinguished by their high productivity, but they also have a certain error during operation, and the surface may remain slightly rough.

Units belonging to the cyclic type process the surface much better, and also perform other operations, but this significantly affects productivity.

However, it is worth noting here that it is the second category of devices that has become more widely used. Since they are more compact, and their base is considered more stable.

Most simple option Assembling such a device with your own hands will use a sawmill as a base. Instead of the front cone of the equipment, it is necessary to install a stop. The bearing for this part will be equipped with the headstock, which is located at the rear. In order to rotate the workpiece, you can use an electric motor or a handle.

The greatest difficulty is in the manufacture of a cutter, and therefore they try to assemble it from several separate elements. It is very important that the material used for this part must be very durable. To move the cutter, an additional rail is used, which also needs to be installed. The final device is very similar to a conventional one. The workpiece is placed in the grooves and rotated, and the cutter moves along. Rounding machines work in the same way.

Assembly steps

The first step is to assemble the frame. The installation height of the frame is 20 cm. The tilt error is allowed in the region of 0.5 mm per 1 meter. The second step is installing the power mechanism, as well as attaching the headstocks. Next, you need to secure the cable for the electrical cable to the installed racks. After this, you can begin attaching the stopper to the power mechanism. An important part of the job will be the grounding equipment for the device if it uses an electric motor. Only after the grounding has been arranged can you begin to connect the motor to the power supply. When this is ready, it is necessary to check the compliance of the phases with the operating modes. If they were connected incorrectly, then when the motor is turned on, reverse rotation will occur. If this happens, then the phases need to be swapped. When everything is ready, you should check again for correct rotation. Lay down the log before all have been successfully completed testing work, is strictly prohibited.

Particular attention must be paid to the headstock fastenings. They are installed as rigidly as possible and parallel to the guides. The axes of both elements must coincide. It is also important to balance the cutter, otherwise the machine will quickly fail.