In our guide, we will tell you how to make an outdoor grill and barbecue oven out of brick yourself. Step-by-step instructions with photos of the construction process will help you understand the details self-masonry this building.

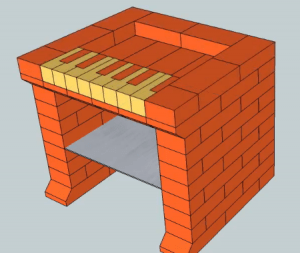

As a result, you should have a barbecue grill as shown in the photo below.

So, you have decided on the type of grill, its size and location. Now you need to build a foundation for it.

Usually such buildings are made on the street, in a gazebo or on a terrace. If the foundation of the gazebo or terrace can support the weight of a brick stove, which is about 3 tons, then you can start construction right away. If you are going to build a barbecue from scratch, then first of all pour a suitable foundation for it: strip or tile.

You will find instructions for building such foundations in our section ““.

The next step will be to install waterproofing under the brick grill. This is done to prevent the lower bricks from getting wet by capillary suction. It will be enough to lay a roll of roofing felt or waterproofing material. At the end of construction, cut off the excess with a knife.

DIY brick barbecue grill. Step-by-step instructions with photos.

Let's proceed directly to laying the barbecue.

We recommend that you first lay out the first row of bricks without mortar and evaluate how your future structure fits onto the foundation. Do not forget to leave 1 cm gaps between the bricks. Also check the diagonals, they must match.

After this, you can start laying the barbecue. The face brick is placed on cement-sand mortar(cement-sand ratio 1:3). To make the solution plastic, add lime or a special masonry plasticizer from the nearest hardware store. The seams are made with dimensions of 8-10 mm, for this they use a metal rod, reinforcement, etc. In places where bricks abut without ligation, the masonry is reinforced perforated tape, wire, etc.

We make masonry with each subsequent row offset by half a brick. To cut bricks you will need a grinder with a stone disc.

We continue to lay out the barbecue grill.

Do not forget to check the verticality of the masonry in the corners at least every 3 rows. Also, check that the lengths of the diagonals of the grill match.

We continue laying.

After you have completed 8 rows of masonry, it is time to make lintels for the barbecue and table top. They should look like the ones shown in the photo below.

You can make such jumpers in several ways.

First, you can hold the bricks together with metal pins and mortar.

Secondly, you can use metal corners.

In our case, we used the second method. We stacked the corners together in an inverted T shape and sawed off half of the shelf. This is what happened.

Take a corner with a size of at least 45x45 mm. A smaller corner will sag. But don’t take it too big so that it doesn’t protrude beyond the edges of the brick.

Make the slot in the brick with a good margin so that the metal does not tear the masonry when heated.

This shelf is invisible to the eye, reliable and beautiful.

We begin to lay it out under (the bottom) of the grill. For the firebox we use refractory fireclay bricks. We do the masonry using a ready-made fireproof mixture from a building supermarket made of clay and sand. Can be used mortar. We make the seams as thin as possible, approximately 3-4 mm.

We use corners to support the bottom of the grill. Remember to leave at least 1 cm of space between the ends of the corners and the brick. This way you will protect the masonry from cracking when the corner expands.

On the first row of the bottom of the firebox we place the second row, covering all the seams of the first. This will prevent the seams from burning out and coals from getting onto the firewood in the firewood box from below. You can, of course, fill concrete slab instead of corners and the first row of the firebox. But in our case it was cheaper and faster to do it this way.

If you fill concrete floor, then one row of refractory bricks for the bottom of the firebox is enough.

We continue to lay out the walls of the grill.

Masonry face brick and the fireboxes can be made both in parallel and alternately. You can first make the walls of the firebox, and then cover it with facing bricks.

Important! We leave a gap of 1 cm between the facing and refractory bricks. The firebox and the cladding should not touch.

We lay the next rows of the barbecue oven.

We are approaching the moment of constructing the combustion arch. We make a circle (an arc structure made of wood) and install it in the barbecue portal. Then we lay the arch, cutting the bricks to the required size. To the middle top point We put up a brick castle. The arch is ready.

Note! The arch made of face brick is covered from the inside with a lintel made of fireclay brick. It is placed on a metal corner slightly above the top of the arch so that it is not noticeable. It looks like this.

The arch is assembled, we continue to remove the walls of the barbecue grill.

Don't forget to check the verticality of the masonry.

We are approaching the moment of constructing the smoke collector.

We bring the top of the firebox and the lining to one level and begin to lay out the smoke collector. We make masonry from solid brick grades not lower than M150. Place it on a cement-sand mortar. We place the first row flush with the inner wall of the firebox. We lay the remaining rows offset by about a third of the brick.

Do not move the bricks more than halfway, otherwise they will fall inside the firebox.

We lay the smoke collector until there is no hole left for the chimney measuring 27x27 cm, taking into account the seams. Your chimney size may differ from ours. In this case, make a smoke collector according to the size of your chimney.

Some stove makers cut off the inner edges of the bricks so that the smoke collector is smooth from the inside. We have the same differences in operation between smooth and ribbed inner surface the smoke collector was not noticed. Of course, this is only true if you have maintained the correct proportions between the dimensions of the portal - smoke collector - pipe (read about proportions below).

This is what the smoke collector looks like without trimmed bricks from the inside.

We continue laying the pipe. Its dimensions depend on the size of your barbecue grill.

After finishing the chimney laying, we cover it with a cap to protect the firebox from precipitation.

We successfully built a barbecue grill, aka a brick barbecue oven, with our own hands! Wait until the solution dries and you can do a test run.

Here we will look at the most frequently asked questions about laying a brick barbecue (grill) with your own hands and the answers to them.

What size should the smoke collector be?

The size of the smoke collector depends on the size of the firebox portal. The optimal ratio should be at least 100-120%. So in our step-by-step instructions, the height of the portal is 6 rows, and the height of the smoke collector is 8 rows.

How tall should the pipe be?

The height of the pipe is proportional to the height of the smoke collector and is at least 100-120% of its height.

What diameter should the chimney be?

The cross-section of the chimney pipe depends on the area of the firebox portal. Optimal area chimney 1/8 - 1/10 of the portal area. Extreme sizes from 1/6 to 1/13.

How to fill the gap between the firebox and the lining?

In front, around the portal, you can fill the gap with basalt cardboard. There is no point in filling the rest of the space. Therefore it is left empty.

Do I need to paint the metal corner in the lintels?

Barbecue (grill) - DIY brick barbecue. Step-by-step video instructions.

When installing a capital brick oven V summer kitchen It should be remembered that any stove increases the fire hazard and requires compliance with all construction standards and regulations. This means that for its construction it is necessary to use a special refractory fireclay brick, which is resistant to high temperatures, but at the same time is an excellent thermal conductor, warming up the room quite quickly. It is important to properly ventilate the stove. At the stage of constructing the foundation, it is necessary to lay out this area with bricks in the place allocated for the furnace. Also, in the future, when constructing a roof, it is necessary to provide for the installation of an exhaust pipe to remove it from the space. working area heat and smoke, etc.

Electric BBQ oven  Gas BBQ oven

Gas BBQ oven

Barbecue oven fired with coal

Barbecue oven fired with coal  Wood-fired barbecue oven

Wood-fired barbecue oven

The barbecue oven can run on electricity, gas or burn coal and wood. Outwardly, it is very similar to a fireplace with a combustion chamber, which is usually located at the level of a person’s waist. A barbecue requires a reinforced foundation, and it is also important to properly install a hood through which heat and smoke will be removed.

BBQ oven with hob in the photo

The barbecue oven can have different configurations - it may include an ordinary hob or oven, grill or barbecue, countertop, space for firewood and storage of dishes. There are such designs that include not only a barbecue, but also a tandoor, a cauldron, a smokehouse and other elements.

If you need a multifunctional large barbecue oven, it is better to resort to the help of professionals, but a small oven can be built with your own hands.

There are many options for prefabricated barbecues and brick ovens. Based on the presented models, you can build something according to own project. The main thing is to arrange everything correctly to minimize the risk of fire, especially when building a stationary brick oven indoors.

Homemade brick barbecue is a more solid option stationary barbecue for arranging a summer kitchen.

BBQ oven in the photo

It will become an excellent decoration and, of course, will allow you to prepare more delicious and varied food. Before you build a brick barbecue, you need to know that it is also called a “barbecue”, and in the standard design plan it should include three compartments.

Of course, the construction of such a barbecue will cost more, but the meat obtained on bricks is much tastier and healthier. Durable and quality brick It is quite expensive, but you can save money by doing all the work on building the barbecue yourself. In this case, we will describe the simplest version of a brick barbecue, which you can easily build yourself, even without much experience.

The presented option of how to build a brick barbecue with your own hands can be changed by using your own dimensions of the parts or adding some additional functional elements to the design. You can build a canopy over the barbecue stove to protect it from the rain, and nearby set up a dining room under a tree, or install such a stove inside the summer kitchen or outside not far from it.

In the latter case, the summer kitchen itself will contain all the necessary kitchen tools, as well as a sink and refrigerator. It is even more convenient to place a barbecue oven outside the summer kitchen - there is less risk of fire, outdoors It will not be so hot to cook in the oven, and also the inside of the summer kitchen will remain cool, unless it is planned to be used in winter - then, naturally, the oven is installed inside.

First you need to choose a convenient place for the barbecue oven. If it is to be installed outside, it is necessary that the distance from the stove to the house or kitchen is not large, since during cooking you will have to constantly bring something from the kitchen - dishes, water, etc.

When choosing a barbecue design, you need to pay attention to the style that is most suitable for the architecture of all buildings on the site. It is imperative to determine in advance the size and design of the stove, where it will be placed (in an open space or inside a summer kitchen), what kind of foundation is required for it (depending on components designs).

Also on preparatory stage it is necessary to think about the lining of the firebox, take into account the shape and height of the chimney, whether the stove will be equipped with an additional oven or smokehouse, what fuel is planned to be used (coal, wood, electricity, gas).

There are really a lot of questions - is it necessary to build a canopy to protect the stove from rain, an additional table and wind protection? And also what facing material will be used, whether to install a heat reflector and a tray under the coal, what the design of the spit, grate or roaster will be, whether the inserts will be made of cast iron.

All this must be thought out in advance and then be sure to draw general form barbecue with drawing of individual parts and indicating their sizes. You should also find a place in advance to place the shelves, since they should fit well into the appearance B-B-Q. It is also necessary to provide space for storing utensils and supplies of coal or firewood.

Barbecue grill

Barbecue grill  Barbecue grill

Barbecue grill

When drawing up a barbecue plan, first of all, you need to take into account that the structure must be stable. It is also important to properly position the barbecue (for grilling). It should be at such a height that it is as convenient as possible for cooking. Typically the grille is installed at a height of 9-10 rows brickwork.

If the grate is too low, you will have to bend over while cooking, which is very inconvenient. And if you put the grate too high, you will have to reach high, and at the same time your face will constantly be close to the burning coals.

The grate and coal tray must be installed on brick ledges or metal rods. They must be removable, since they must be periodically cleaned of rust and stored in the house for the winter.

In a barbecue, you can use a regular stove grate. It should be borne in mind that it should be larger than the hearth with burning coals, so that the finished barbecue can be moved to the side next to the hearth, but at the same time keep them hot. The roasting rack must be protected from the wind. Under it there should be another grate, with smaller cells, on which burning coals will be located, and under it a tray into which burnt coals will fall.

Watch how to set up a brick barbecue with your own hands in a video where all types are presented production elements and advice from the experts:

Diagram, laying and ordering of a brick barbecue with your own hands

Laying a brick barbecue consists of several stages - choosing a location, drawing up a barbecue plan, building a foundation, erecting brickwork with the installation of all structural details, constructing a pipe, cladding and designing the building.

To lay a brick barbecue with your own hands with three compartments you will need following materials and tools:

- sand;

- cement;

- gravel;

- reinforcing mesh;

- brick;

- ceramic tile;

- Master OK.

Currently, you can buy ready-made kits for arranging a barbecue oven. The standard set includes the barbecue grill itself, a charcoal tray and fasteners. These kits can be used when building a brick barbecue with your own hands.

What the foundation of the furnace will be depends on its size. The do-it-yourself brick barbecue scheme allows for the possibility of making a concrete strip foundation, but for a more massive structure a tiled one will be required.

The foundation completely hardens approximately 2 weeks after pouring the concrete, and only after that can you begin to build the barbecue itself.

First, you need to lay 2 layers of roofing felt on top of the foundation to protect the structure from moisture, after which you can begin laying the brick stove. In this case, we are considering the option of a standard barbecue consisting of three compartments. From brick you will have to lay out a figure in the shape of the letter “W” with 4 partitions. What kind of brick barbecue will turn out, the order and diagram can be shown in advance by carefully examining the barbecue construction plan.

The rows must be laid out in a certain sequence - each next row shift in relation to the previous one in a checkerboard pattern. This is the so-called half-brick masonry, which should provide the necessary bond of brickwork. Even before starting the laying, you need to tighten the cords indicating the position of the future wall of the barbecue, and use a trowel to apply a layer of mortar. This needs to be done along one of the walls. Then you should make small grooves in the mortar and begin laying the first row of bricks, checking it with a horizontal level.

In total you will need to lay out 8 such rows. If you plan to place a sink in the 3rd compartment, you need to leave a hole for the drain in the 6th row.

First you need to build floors that combine two adjacent compartments future design. This requires cutting off the metal corners. required length and put them on top, and then make the same, but a continuous ceiling of bricks in one row. To lay the 2nd layer, you must definitely use a heat-resistant clay mixture intended for ovens and braziers, since it is impossible to make a reliable grill using cement alone.

STEP #1

STEP #1  STEP #2

STEP #2

STEP #3

STEP #3  STEP #4

STEP #4

STEP #5

STEP #5  STEP #6

STEP #6

The most difficult stage of the work is laying the furnace itself. This can be an ordinary rectangular direct-flow furnace without a blower. The thickness of its back wall should be three bricks. There must be room in the front for a door. On the side where the oven will adjoin the brazier, you should leave a hole the size of two bricks.

It is necessary to make protrusions for the roasting grate and the charcoal tray. When building a brick barbecue with your own hands, order plays a very important role. important. When laying the 5th row, you need to form a supporting ledge, and then lay the 6th row of bricks across - the entire row of bricks should protrude from both sides of the wall. The next three rows again need to be laid in half a brick. In this way, protrusions for the grate and tray are formed.

Sometimes it happens that there is no pallet the right size, which would fit the width of the brick projections, and then a metal shelf can be used to support it.

Then, in the 10th row, you need to build another ledge and add three more rows on top using the spoon dressing method - this is the end of the main part of the barbecue.

If the stove design will use metal rods to support the barbecue, then during laying between the 6th and 7th rows, these metal rods must be laid out in all three walls. This should be done in such a way that the rods protrude from the walls by 70-75 mm and a grill with a tray can be installed on them.

The rods must continue to be laid until the 10th row in each subsequent row. This is required in order to install the roasting rack at the required height.

After this, all that remains is to lay out a rectangular roasting pan and make a pipe of any shape. This arrangement of brick barbecues is used in all such structures without exception.

It is also necessary to arrange a barbecue work surface. The simplest way is to build a low - 6 rows high - brick wall.

This construction must be done on a separate strip foundation, which is poured parallel to the side walls. Such a small wall is called a plinth wall. You need to lay it out so that the brick rests side by side.

After this you need to cut plywood sheet and lay it between the side wall projection and the baseboard wall. Lay boards on the sheet and cover them with tiles or ceramic tiles. You can even use ordinary paving slabs to cover the working surface.

Expert advice

After completing the construction of the barbecue and its working surface, it is necessary to begin processing all the seams. For this purpose it is used cement mortar, which needs to fill all the seams and rub in thoroughly. Before the solution hardens, it is necessary to run jointing along the seams to give them roundness. If the craftsman does not have jointing at his disposal, this can be done using a regular cutting of a garden hose.

If the plinth wall will be connected to the main structure, then up to the sixth row the structure must be built in the form of the letter “E”, and then continue laying the side and rear walls of the barbecue itself. As a result, a niche is formed under the grate with a tray, which can then be used to store charcoal or firewood. If this opening is equipped with a door with a handle, it will be quite possible to store dishes here.

With this, the main functional part of the stove will be built, and then the structure can be supplemented with various shelves and other elements, decorated at your discretion, etc.

The constructed furnace must “settle” for several days for the solution to completely harden. If you light a fire in it until completely dry mortar, its walls may crack.

In the future, when using the stove, it is necessary to clean the barbecue after each cooking so that dirt and grease do not accumulate, otherwise in the future you will have to thoroughly clean the stove.

DIY construction of a barbecue oven with a brick grill (with photo)

The construction of a brick barbecue does not necessarily always involve the monolithic construction of all structures. You can build a brick barbecue oven with your own hands in the so-called temporary version. This is convenient if there is no space to build a permanent, stationary structure. If necessary, such a stove can be disassembled and folded for storage in a specially designated place, and then reassembled. This is easy to do, since such a furnace is built without the use of cement or clay mortar. This is the cheapest and fastest to build brick barbecue structure. At the same time, it is very effective, because bricks laid without mortar freely allow oxygen to pass through, which contributes to better and complete combustion charcoal.

The shape of such a barbecue can be rectangular

The shape of such a barbecue can be rectangular  The shape of such a barbecue can be round

The shape of such a barbecue can be round

If you often spend time with friends, love meat or fish, then you simply need a brick barbecue. This functional feature will allow you to cook even large pieces of meat, turning them into a delicious, aromatic dish. We invite you to get acquainted with the design features of detailed buildings and the sequence of their construction.

Design and principle of operation of a brick barbecue

Part modern complexes Usually there are more than three fireboxes. Their dimensions are determined at the project development stage. This device makes the barbecue oven multifunctional. A Russian stove with an oven, a brick barbecue, and a smokehouse are provided. There are other possible options. There are three or more channels, which, thanks to the valve system, can be isolated from each other.

The barbecue includes a grate installed 20-25 cm below the level of the side walls. The coal tray is solid, which provides sufficient draft. The coal smolders, so gradual, even cooking occurs. various dishes. The height of the walls ensures the formation of a warm air-smoke cushion, due to which the prepared food acquires a characteristic smoky aroma.

Where is the best place to organize a barbecue area?

When choosing a barbecue location, take into account whole line factors. It should be located:

- away from flammable substances;

- away from trees;

- on the leeward side of buildings;

- far away from .

It is advisable to locate the complex away from the house (at a distance of at least 5 m). At the same time on minimum distance from the kitchen so that the housewife can cook comfortably. It is advisable to pave the complex using either brick. All wooden elements coat with fire retardant.

Types of ready-made brick barbecue kits for a summer residence

When you decide to purchase a ready-made brick barbecue set for your dacha, pay attention to the barbecue stove:

- "Sadovaya". Suitable for year-round use. Consists of eight elements and steel pipe. Mounted on . With a height of 1.8 m, it has dimensions of 1×0.8 m;

- "Prestige". Weighs 600 kg. With a height of 2.4 m, it has dimensions of 1.3 × 1.05 m;

- "Picnic". Weighs 670 kg. Allows installation of a spit. Powered by wood and coal;

- "Fairy tale". Weight: 500 kg. Only charcoal should be used for cooking. With a height of 2.3 m, it has dimensions of 1.2 × 0.8 m.

Before you buy a brick barbecue, keep in mind that reviews of ready-made structures are not always positive.

More details on ForumHouse: https://www.forumhouse.ru/threads/199413/

How to choose a brick barbecue design: information relevant when developing a project

Among the many variety of options The most popular barbecues are:

- barbecue stoves, made with a smoke collector above, through which smoke is removed from the grill;

- barbecue complexes with wide functionality;

- barbecue fireplaces.

Complexes are performed angular and frontal. They can have many elements, the need for which in each specific case is determined individually. Judging by the drawings and photographs, the dimensions of a front-type brick barbecue are usually 3.7 × 1.3 m, corner ones - 2.5 × 3 m. Good design may include not only a roasting pan, but also a smoker, an area designed for food preparation, various cabinets and much more.

Attention! Choosing a large complex will allow you to diversify the list of prepared dishes.

Frontal complex with wide functionality

Frontal complex with wide functionality Popular brick barbecue projects for DIY construction

If you decide to make a brick barbecue on your own, projects from already implemented solutions will come in very handy. We invite you to get acquainted with popular options that can be recreated on.

1 of 6

DIY construction of a brick barbecue oven

When starting to build a brick barbecue oven with your own hands, you need to prepare properly. You will need not only materials and tools, but also precise knowledge of the technology and drawings in accordance with which the work will be carried out. We suggest you figure out how to independently build such a building on your site.

What materials and tools are needed for work: an indicative list

When choosing materials for construction, you need to know which brick to use for a barbecue. You will need red and fireclay. The latter is intended for laying the firebox.

Attention! The required amount of brick depends on the design features and dimensions of the stove being built.

You will also need:

- furnace casting. The list, dimensions and quantity are determined at the drawing development stage;

- clay;

- for the device or the main components for its preparation;

- reinforcement to increase the strength characteristics of the foundation;

- Metal sheet;

- boards for ;

- waterproofing material;

- trowel;

- construction level;

- for wet cutting of bricks;

- with suitable circles;

- hammer with rubber striker;

- template for a semicircular arch.

How to prepare a drawing for a brick barbecue with your own hands: useful tips

When starting to develop a drawing of a brick barbecue with your own hands, consider the following points:

- area and strength characteristics of the foundation of the future structure. The foundation must be designed for future operational loads;

- design features and height of the future furnace;

- design features of the roasting pan, skewers and grates;

- the presence of a canopy or gazebo. If they are available, it will be possible not to depend on weather conditions;

- Availability additional elements. In addition to the barbecue, you can provide a smokehouse or. They must be present in the drawing;

- wind protection system;

- coal storage area;

- design features.

A comment

Team leader of the repair and construction company "Dom Premium"

Ask a Question“When starting to develop a drawing of a brick barbecue with your own hands, download for free already ready-made solutions. They can be used as a basis."

Laying the foundation

The service life of a brick barbecue in a gazebo depends on the quality of the base. Work begins with preparing the pit. For this they remove fertile layer and remove the soil to a depth of 20-25 cm.

Attention! The dimensions of the foundation being laid depend on the size and design features of the barbecue. They should be 0.5 m more sizes stoves in all directions.

| Illustration | Description of action |

| A fifteen-centimeter layer of medium-fraction crushed stone is poured and compacted onto the leveled bottom of the pit. Pour a small layer of concrete. Let's do it. To do this, we drive the rods at equal distances, and also lay them lengthwise and crosswise, tying them at the intersection point. |

| Pour concrete to the level of the pit, close it from above metal sheet and leaves it for three days. The sheet should be laid on the bricks to prevent its contact with the poured mortar. |

| We set up the formwork and continue pouring the base. |

If you want to learn the sequence yourself, watch this video.

Preparation of clay solution

Dark red clay is selected for laying the stove. It is soaked for a day before preparing the solution and mixed thoroughly every other day. Sand is added to the soaked clay in a ratio of 1:2. To increase plasticity, glue for stoves and fireplaces is added to the composition (about 3% of the volume). The composition is thoroughly mixed. You can start laying.

Step-by-step brick barbecue laying

Arrangement of the firebox and chimney

Heat-resistant bricks are used for the firebox and chimney. The formation of the pipe usually starts from the 18th row. In each of them, a quarter of the brick is removed to narrow the hole. This is done up to the 28th row. should be equipped with a valve.

Attention! Instead of brick, let's install a metal box.

We think you will find the following video with instructions interesting.

External finishing of the barbecue oven

Getting started external design, the finishing should be coordinated with the style of the house and other buildings located on the site. All elements of the complex should have a single decor.

How much does it cost to build a turnkey brick barbecue - price review

Not everyone can carry out the entire range of work on their own. But many are interested in the price of a turnkey brick barbecue. Here everything will depend on many factors, including the size of the building and its design features. If you decide to order a brick barbecue, pay attention to the average cost of popular models.

Rest on fresh air V country house or a dacha is not complete without cooking in the open heat. You won’t surprise anyone with banal kebabs or baked vegetables, but in such conditions you can cook real pilaf or other complex dish only in a special fryer. This is a barbecue oven, the design of which includes the installation of a cauldron.

General structure of a barbecue oven with cauldron and sink

Barbecue oven is permanent structure for cooking various dishes over the heat of hot coals. The peculiarity of this installation is that the cooking process is carried out on a metal grate without an open flame, and the fryer is not covered with a lid.

In terminological terms, the concept of “barbecue” means a method of baking meat or plant products over smoldering coals at a temperature in the range of 100–130°C.

For the convenience of cooking, such devices are modernized by adding additional compartments and installations. A design that combines a barbecue oven, a roasting pan with the ability to install a cauldron, and an extension with a sink has become very popular. It should be noted that the fryer can be easily converted into regular stove, if you remove the cauldron and put cast iron rings on the hole different sizes, forming a continuous surface.

A large barbecue oven has many positive and several negative qualities.

Table: advantages and disadvantages of a barbecue oven

| pros | Minuses |

|

|

Photo gallery: ready-made barbecue oven projects

The design using red and fireclay bricks looks very solid  The barbecue oven can also be placed in the corner

The barbecue oven can also be placed in the corner  Complex design needs help professional builders

Complex design needs help professional builders  Light finish has an attractive appearance

Light finish has an attractive appearance  A creative approach to construction will help make original decoration for the dacha

A creative approach to construction will help make original decoration for the dacha  The unusual shape of the barbecue oven attracts the eye

The unusual shape of the barbecue oven attracts the eye

Preparation for construction: drawings and optimal dimensions

The construction of a barbecue oven structure must be preceded by preparatory measures for choosing a construction site, drawing up drawings and diagrams.

When choosing a site for construction, you must be guided by the following rules:

- Between the furnace complex and residential building there must be a distance of at least 5 m.

- Access to the kitchen should not be too far from the structure. If necessary, they can be located under one roof.

- The building should be located away from neighbors’ residential buildings, as odors and smoke can irritate them.

- The decision of all construction issues should be entrusted to specialists.

- Before construction, it is necessary to conduct a soil study and, in accordance with its quality, select the appropriate type of foundation.

The size of the future barbecue oven plays an important role.

If the surface with the sink, barbecue grill or cauldron is placed too low, then after a while your back will get tired, and if the working surfaces are located too high during the cooking process, you will not be able to avoid burns.

To find the golden mean, you should adhere to the rule - the optimal height of the working surface of the barbecue oven should be slightly below the level of the elbows of the cook.

If the width of the selected area does not allow making a wide structure, then this optimal parameter we can consider the value to be 240–250 cm. Such a stove complex will be compact and convenient. The width of the roasting pan should be 63–65 cm.

The size of the stove for the cauldron will be 3.5 bricks on each side, which corresponds to 87 cm.

Selection of material, calculation of required quantity

Various materials are used to build barbecue ovens, including brick, metal, stone and clay.

The latter can be used to make a monolithic structure.

Clay was used in ancient pottery. The first historical mentions of such structures were found in the 3rd millennium BC. Nowadays, this type of furnace is used extremely rarely. To make it you need a special type of fatty clay.

Stone barbecue stoves are more common, but are not widely popular, since their construction requires rubble stone, sandstone and limestone. The disadvantage of this material is that it different shapes, which is why each element has to be carefully selected to each other.

Furnace complexes made of metal are widely used nowadays due to the relative cheapness of the material and the ease of its processing. Goes on sale a large number of already ready-made structures. At home, such structures are made in compact sizes.. For this, steel sheets or pipes with a thickness of at least 5 mm are used. A popular option is to use old propane tanks. The wall thickness and dimensions of these containers are suitable for the manufacture of such structures.

The most convenient, high-quality and durable material for a stove is brick. He has standard sizes and shape.

It should be noted that not any type of brick is suitable for building a barbecue oven.. For example, silicate cannot be used. For braziers, ovens and other structures operating at high temperatures, fire-resistant red and fireclay materials are used. The combustion chamber is lined only with the second type.

In addition to the main building material, required:

- Concrete mix to lay the foundation.

- Boards or plywood panels for making formwork.

- Reinforcing bars for the construction of a metal frame that strengthens the concrete base.

- Sand and gravel for the foundation.

- Wire, plastic clamps or welding machine for securing all connections of the reinforcement structure.

- Waterproofing material for foundations. For this, thick polyethylene or roofing felt is usually used.

- Metal sink, faucet, drainage devices, rubber hose.

- Metal corners for installing a countertop with a sink, fasteners for a barbecue grill and other structural elements of the stove.

All these materials require careful calculations.

Bricks, clay mortar

To build a barbecue oven you will need 810–820 fireproof red ones, as well as 30–35 fireclay ones. The thickness of the seams between them is 3–5 mm.

Concrete, sand, gravel

Since the barbecue oven will combine several working areas, its design will occupy a large area of land. In order for this complex to be stable, it is necessary to make a permanent foundation. A slab foundation is suitable as such.

To calculate exact amount concrete need to know overall volume grounds. To do this, you need to use a special geometric formula. Since the foundation will be made in the form of a flattened parallelepiped measuring 270x100x20 cm, the volume of the concrete mixture must be calculated using the formula V=h³, where h is the length of the side of the figure. Using an example, it will look like this: 2.7∙1.0∙0.2=0.54 m³.

Using the same formula, the volume of sand and gravel is calculated. The base requires a layer of each material 10 cm thick. It follows that sand is required: 2.7∙1.0∙0.1=0.27 m³. This is the same value for gravel.

Armature

To prevent the foundation from cracking under the weight of the stove, it is necessary to strengthen it. For this you need metal carcass. For its manufacture, reinforcing bars with a thickness of 12 mm are used. The metal structure is a three-dimensional frame in the form of two gratings, which are connected to each other by pieces of reinforcement 15 cm long. The size of each cell in the frame is 10x10 cm.

It is more convenient to calculate this material in linear meters. To do this, it is necessary to determine the total length of all the reinforcement for the frame. To do this, you must first calculate the number of rods located along the length of the frame, then along the width and between the gratings.

The rods are calculated according to the length of the structure. The length of each of them is 95 cm. It is necessary to determine how many rods will be placed along the length of the foundation if the distance between each of them is 10 cm. For this you need 270:10 = 27 pieces. It is necessary to add one more rod, since it will close the structure from the other edge of the frame. To find out how much it is in linear meters, you need 27∙0.95=26.6 m.

The same calculation principle is used to calculate the amount of reinforcement along the width of the base. For this, 100:10=10 pieces, in linear meters it will be: 2.7∙10=27 m.

It is necessary to add these values to get the overall parameter for one grid: 26.6+27=53.6 m.

Since the design provides two gratings, then 53.6∙2=107.2 linear meters.

Now you need to calculate the number of reinforcement elements connecting the two parts of the frame. These rods are located along the perimeter (at the intersection of each rod), as well as inside the structure, at a distance of 90 cm from each other in rows.

From previous calculations, the number of rods along the width and length of the frame is known: 28 + 10 = 38 m. This value must be doubled, since the elements are located along the perimeter of the structure: 38∙2 = 76 pieces. Inside the frame there are two more rows of 10 pieces, so 76+20=96 pieces. It is easy to determine this value in linear meters: 96∙0.15=14.4 linear meters.

Waterproofing for foundation

To calculate the required quantity waterproofing material, you need to find the area of the base. The area of this figure is determined by the following formula: S=a∙b, where a is the width, b is the length of the rectangle. Let's substitute the values: 2.7∙1.0=2.7 m².

Step-by-step instructions for making a barbecue oven with a cauldron

When the site for construction has been selected and prepared, drawings and diagrams of the future structure are drawn up, and necessary materials purchased, you can begin the actual construction of the barbecue oven. To do this you need to do the following:

- In the selected area, make markings for the foundation of the future furnace. You can use cords and stakes for this.

- In accordance with the markings, dig a pit 35 cm deep. Its bottom must be leveled and compacted.

- Pour sand inside the pit to form a uniform layer 10 cm thick. The material will be better compressed if it is wetted.

- Pour the same layer of gravel on top.

- From edged boards or thick plywood to make formwork. Its height must be at least 25 cm so that the level of poured concrete does not reach the top edge of the side.

- Place the formwork on the bottom of the pit parallel to its walls.

- From reinforcing bars 12 mm thick, make a three-dimensional frame with cells measuring 10x10 cm. The structure should not touch the bottom, so place it under it in a checkerboard pattern. wooden blocks or fragments of bricks.

- Pour the concrete mixture. For the foundation, use cement grade M 250. Reinforcement frame should be completely hidden under the liquid solution.

- Cover the foundation with waterproofing material. To do this, use roofing material or thick polyethylene. This is necessary so that the moisture inside the concrete evaporates evenly. If you leave the foundation uncovered, then upper layer will dry quickly. In the future, this may cause the base to crack. The concrete mixture will harden in 4-5 days. For the first two days, you need to open the waterproofing and water the base with water every 10–12 hours. Polyethylene or roofing felt prevents moisture from evaporating quickly. This ensures uniform hardening of the slab foundation.

- When the base is dry, it must be covered with a layer of roofing material or other waterproofing material, and only lay brick on it. The first 6–7 rows are not held together with cement mortar.

- The barbecue oven must be arranged in accordance with the diagram. Each subsequent row must be shifted relative to the previous one in a checkerboard pattern. This method has a name - half-brick masonry. This ensures a reliable bond of the material.

- For the combustion chamber it is necessary to use fireclay bricks. It can withstand temperatures over 1600°C. Check each row for vertical and horizontal using building level, square and plumb line.

- Create places for ash pans and doors.

- For a cauldron, it is necessary to make a combustion chamber in the form of a straight or tapering cylinder. This part of the furnace is made of fireclay bricks.

- Construction of the chimney can begin only after the mortar in the masonry has completely hardened. The pipe can be built not only from brick. Metal is often used for this.

- Install faucet and sink. Connect the water supply hoses.

- After the solution has completely dried and the furnace structure has shrunk, you can begin finishing it. For this you can use stone, brick, tiles or whitewash.

- The finishing material must be attached to the prepared base. To do this, you must first plaster the surface using a mounting mesh with a cell size of 10x10 mm.

- If you choose whitewash, then you need to use one that does not get dirty. Slaked carbide or lime salt are suitable for this.

- To decorate with stones and tiles, it is enough to clean the surface from dust and use ready-made adhesive mixtures.

Video: DIY garden barbecue oven

Nuances of use

In order for the barbecue oven and its working elements to please you for a long time, you need to use it correctly:

- The heat will be uniform if you first remove the old ash.

- Smoke from residues under the ash pan from previous cooking can spoil the taste of the dish.

- Before use, a new cast iron cauldron must be lubricated. sunflower oil, and then heat it on the stove for 20 minutes. Add oil if necessary. After the specified time, leave the cauldron to dry, then drain the remaining oil. Wipe the inside with a dry cloth. It is now ready to use. Each subsequent dish cooked in it will be tastier.

- It will be more comfortable to use such a stove if the floors in front of it are laid with stone, and a canopy or roof is made over the brazier.

You can build a barbecue oven with your own hands, if you strictly follow the instructions and treat this process responsibly. This design will serve you for a long time and will fully meet your expectations.

You have a dacha. You want to make it not only beautiful, but also convenient and comfortable for your family and friends to relax. And so that everything doesn’t cost too much. Don't know where to start? Do-it-yourself barbecues and barbecues for a brick dacha made from a photo are an ideal start for arranging summer cottage. We assure you that after reading this article and looking at the drawings, you will build an ideal barbecue on your site, on which you will then cook delicious and healthy food.

A step-by-step guide to preparing and building a DIY brick barbecue

Preliminary work (layout and drawings)

Before you build a brick grill, you need to carefully consider what it will be like. We recommend paying attention to the following points:

When you decide what kind of barbecue you want to make, make detailed drawings with exact dimensions. Thanks to them, you will not only be able to correctly build the structure itself, but also calculate the amount of materials needed.

Choosing a place for the barbecue

Brick barbecues can be located anywhere in the summer cottage - in the garden, in the gazebo, on the terrace - as long as it is convenient. But we advise you to consider the following recommendations:

- The first and most important point– fire safety! Don't build garden barbecues nearby wooden buildings, dry trees and bushes.

- There should not be a playground nearby.

- Convenient if you bake and Brick wall summer kitchens will be located nearby, so as not to have to run far for groceries and everything else.

If the project includes a sink, build a water supply nearby.

To ensure that the future roaster stands well and firmly for many years, make its base as reliable and stable as possible. The dimensions and strength of the foundation depend on the dimensions of the planned structure. In any case, the foundation should be larger in area than the barbecue by approximately 50 cm on each side.

After two weeks (if it’s hot, maybe less), when everything has hardened well, you can start building a barbecue with your own hands.

Choosing a brick for a barbecue

Here again we should remember about fire safety. If the barbecue is indoors, you should take a special fire-resistant fireclay brick, it contains a lot of clay, due to which it withstands well high temperatures and quickly warms up the room.

Types of bricks used to build barbecues

If the future construction is planned to be outdoors, then professionals do not recommend making everything from fireclay bricks, since they do not like moisture. It's better to take a full-bodied one ceramic brick M200 or facing. The interior of the firebox itself will be made of fireclay bricks.

Upon request, on final stage During the construction of a barbecue, its decorative finishing is done.

Preparing the solution

For cladding you need a cement-sand mixture, and for laying the stove itself, clay-sand with the addition of a small amount of cement for strength. You can take ready mixture for ovens and prepare it according to the instructions.

To prepare your own clay solution, you will need:

- red clay;

- sand;

- cement;

- water.

The clay is filled with water and left for 5-6 days. Then it is thoroughly mixed, sand and cement are added little by little (a glass of cement 400 per bucket) and mixed again. The mixture is ready to use.

After the foundation hardens before construction, two layers of roofing felt must be placed on it for waterproofing. This is done so that the brick draws less moisture from the base, this will extend its service life.

Then we determine the position of the wall, apply the solution and begin to build a brick grill with our own hands.

Be sure to check everything with a level so that the masonry is even, as this will affect the quality of the stove in the future.

Laying a simple brick grill (arrangement)

To build such a barbecue, carefully consider the diagram according to which step-by-step masonry is carried out, the so-called order.

The so-called half-brick masonry is performed: each odd row (1,3, etc.) begins with a whole, and each even row (2, 4, etc.) with a half. This is done for a bunch of bricks.

We lay a ceiling on top of the 4th row, on which dishes can then be placed.

On the 8th row you need to put 4 thick-walled corners, as shown in the figure. We lay the 9th row on the corners.

In the 10th row, all the beauty of this barbecue is “piano keys”. They can be cut with a grinder from white fireclay and red facing bricks.

The last 2 rows - and the grill is ready. Please note that in the 11th and 12th rows longitudinal halves of bricks are used.

The skewers and grill will then be placed on them.

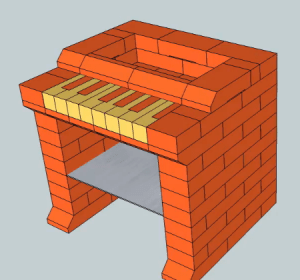

View from all sides

This is what our brick piano grill looks like from different sides.

Option 1 - drawing with dimensions (click to enlarge)

Final result with dimensions.

Option 2, improved - drawing with dimensions (click to enlarge)

Another option for a barbecue piano. It is wider and back wall built from the very bottom. Watch the video for the laying process of this option.

This was the one that was easy to build on your own, even without experience in this field.

Do-it-yourself brick barbecue - step-by-step construction with real photos

Let's consider another option, more complex - how to make a brick barbecue with your own hands, which includes two lower compartments for firewood, dishes and other small items, a combustion chamber, a table top and a chimney at the top.

For the construction of the structure itself in this case they used facing brick, and fireproof for the inside of the oven.

Initial stage of construction

We begin laying in the same way as described above. The lower part will be in the shape of the letter “W”, only the compartments will be different in width. The wider one for firewood will have a firebox and chimney above it. The second is for dishes and other accessories; there will be a table top at the top.

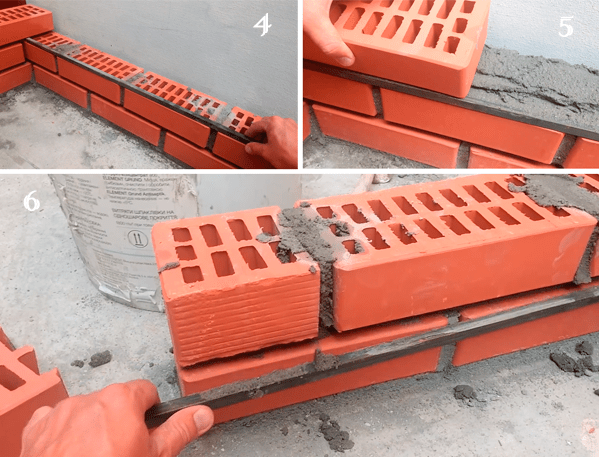

We make even seams between rows

To ensure that there is an identical and even seam between the bricks everywhere, a metal strip is used here when laying, the cross-section of which is square with a side of 12 mm. But we recommend taking something thinner - 5-10 mm will be enough. You also need to constantly control the level of verticality and horizontality of the masonry.

Brick laying process

The plank is placed on the edge, as shown in photo 4, and then carefully covered with mortar. On the side where the bar was placed, we place the mixture equally with it, on the other side, a little more, in a slide. We lay the brick, hold it with one hand on the side of the plank, and lightly tap it with a hammer on the other side to level it. When the solution dries a little, remove the bar.

To make the laying process move faster, there must be several planks, since they are needed for each row.

Lay out the bottom part - the first 10 rows

According to this principle, 10 rows are laid out.

Preparing the base for the firebox and countertop

Next will be the firebox and countertop. On the 10th row we place reinforcement with a diameter of 12 mm. The distance between the rods is 70 mm. Formwork is placed between the reinforcement so that the mixture does not fall down when the seams between the bricks are filled.

Professional advice: it is better to take metal corners, as there is a possibility that the reinforcement will bend under the weight.

Lay out the brick and fill with mortar

Bricks are laid out at equal distances from each other over the entire area. Those that fall on previously erected walls are placed on the mortar, the rest are simply placed on the formwork. Then the gaps between the bricks and the surface are filled with mortar.

We form the combustion chamber and vault

After drying, the firebox is erected - 8 rows are laid out vertically. Next, the back part, which is located near the wall, is also erected, and the remaining three sides are narrowed upward by half a brick. So another 9 rows are laid out.

We are building a chimney

The next stage is the chimney. In this case, 20 rows are made of brick, and at the top there is a stainless exhaust pipe. A high chimney is needed so that the smoke does not disturb you or your neighbors, and the draft is better.

The last stage of construction - finishing the countertop and firebox

AND finishing touches– the countertop is tiled, and the inside of the firebox is lined with refractory bricks.

Final result

After a few days for complete drying, the barbecue is ready for use.

We recommend watching a video that shows the entire process of laying a garden brick oven.

Below in the gallery you can see more photos of barbecues and barbecues for your dacha made from brick with your own hands, and choose the one that is suitable in style, functionality and location specifically for your site.

In the gazebo

In the gazebo  On the terrace

On the terrace  With hob

With hob  On the street

On the street  With built-in smokehouse

With built-in smokehouse

There is no fundamental difference between barbecues and barbecues, except that in the first, food is cooked on skewers, and in the second, on a grill. Both can be done on one structure, the construction of which will be discussed.

Often, a country barbecue is a simple street building under open air. A brick barbecue is a more complex device, which can be located in a summer kitchen, gazebo or outdoors, but it already has a chimney and, in most cases, a cover to protect from rain and snow.

A temporary brick cooking device is a great summer option.

If you do not plan to be at the dacha in winter, then a barbecue or grill made of brick without mortar is perfect for this purpose. In the spring it can be easily and quickly folded and disassembled for the winter.

Laying scheme without mortar

Here is a diagram and step-by-step instructions that show how to make similar grills and barbecues from brick.

If the barbecue is planned to be small (9-10 rows of bricks), you can simply level and compact the ground well. For a larger structure, it is better to pour a foundation.

We begin to lay out the bricks according to the same principle as in the previous versions, but in a circle and with gaps of approximately 50 mm.

Lay on top of the 5th row steel sheet, which will serve as a tray for coal.

Add 2 more rows and install a cooking grate. Then 2 more rows for protection from the wind.

To build such a round barbecue, you will need a little more than 100 bricks.

This is one example of a temporary barbecue, you can change it at your own discretion. Or choose for yourself and build one of the options shown in the photo below.