Comfortable and cozy housing is the place where you want to constantly return after a hard day at work. This is a real dream of every person and, it should be noted, it is achievable. Easy enough to equip quality system heating (including performing such a process as piping heating radiators with polypropylene or ordinary metal pipes), which will warm the house on cold winter evenings, creating an impeccable atmosphere of comfort, making the home cozy.

Tying heating system radiators: basics of the process

Piping a heating radiator is one of the main stages of arranging a modern heating system. If such a procedure is performed at a high and high-quality level, the highest quality, reliable and productive operation of the equipment can be guaranteed.

The strapping process is based heating radiators on the installation of special shut-off and control valves. Such equipment is designed to regulate the heat transfer of radiators, to ensure their emergency shutdown in the event of an accident or when replacing and flushing the system.

Radiator piping options: choosing a specific option

Currently, the heating radiator piping scheme can be very different. It should be noted that you need to choose a specific option with special care, taking into account a lot of parameters and factors. The type of equipment, financial costs and, of course, the comfort in the home and the performance of the heating system will depend on the correct choice of scheme.

Among the main options for piping heating radiators are:

- Option using shut-off valves. The most affordable financially, but at the same time one of the most inconvenient options. The “inconvenience” of using taps for tying batteries lies in the inability to control the radiator and adjust the temperature in the room.

As you can see in many photos and videos on our portal, in the piping diagrams, the installation of taps is carried out at the inlet and outlet of the radiator. At the same time, the house owner has the opportunity to independently disconnect and dismantle the batteries - to do this, you just need to turn off the radiator;

- Manual adjustment. This option involves installing a special control valve yourself. Thanks to such equipment, you can easily regulate the flow of water that enters the radiator from common system heating.

An excellent choice for any apartment, because in a centralized heating system it is not possible to achieve precise temperature control without special equipment. It is also planned to install bypasses - sections of pipelines directly connecting the supply and return pipelines.

Installation of such a pipe is carried out in the section from the rack to the valve to regulate the coolant supply;

- Automatic adjustment. The instructions for this type of radiator piping involve installing a special valve with a thermostatic head at the inlet of the battery. Through simple turn heads, you can achieve the desired temperature of the coolant that enters the radiator.

Subsequently, this temperature will be maintained automatically by changing the amount of water supplied to the radiator. The only disadvantage of such a system is the price of automatic equipment - it is slightly higher than that of manual or, for example, shut-off valves.

Advice. If the choice fell on piping heating radiators using an automatic adjustment system, then it is important to take care to ensure free access of air to the thermal head.

Tying heating radiators using an automatic adjustment system: features

In addition to the thermal head itself, the system automatic adjustment for supplying coolant to the heating radiator, when piping it, some other elements can be used - remote heads. They are used if it is not possible to ensure free access of air at room temperature to the thermal head.

Several options are possible:

- Installation of a thermal head with a capillary tube. In this case, the head will regulate the temperature in the radiator automatically, simply transmitting force through the capillary tube;

- Installation of an electric head with a servo drive on the valve. The principle of operation of the system is quite simple - a thermostat mounted anywhere transmits a signal to the valve, which, in fact, regulates the water supply to the radiator and its temperature.

It should be noted that it is a valve with an electric head and a servo drive, chosen as an option for radiator piping, that allows one to achieve a lot of advantages:

- The ability to simultaneously connect several radiators to one thermostat, providing centralized temperature control in the batteries;

- You can install a thermostat with a special programmer that automatically adjusts thermal conditions depending on the days of the week or time of day;

- The thermostat can be installed regardless of the distance from the radiators.

Results

Installing heating radiator piping is an important stage in arranging any heating system of a modern house or apartment. As a rule, the greatest effect from the use of piping fittings is felt in centralized systems, because it is possible to ensure smooth temperature control in the room.

Currently, the choice of piping options is quite large, and therefore you can choose the optimal one depending on many factors, ranging from the features of the system and radiators to financial capabilities. You can entrust the work on piping radiators to either professional craftsmen or do the procedure yourself, fortunately there is nothing complicated.

You can purchase an arbitrarily powerful heating boiler, but still not achieve the expected warmth and comfort in your home. The reason for this may well be incorrectly selected final heat exchange devices indoors, as which are traditionally most often radiators. But even assessments that seem to be quite suitable according to all criteria sometimes do not meet the expectations of their owners. Why?

And the reason may lie in the fact that the radiators were connected according to a scheme that is very far from optimal. And this circumstance simply does not allow them to show those output heat transfer parameters that are announced by manufacturers. Therefore, let's take a closer look at the question: what are the possible connection diagrams for heating radiators in a private house. Let's see what the advantages and disadvantages of certain options are. We'll see what technological methods are used to optimize some circuits.

Necessary information for the correct choice of radiator connection diagram

In order to make further explanations more understandable to the inexperienced reader, it makes sense to first consider what a standard heating radiator is, in principle. The term “standard” is used because there are also completely “exotic” batteries, but the plans of this publication do not include their consideration.

Basic design of a heating radiator

So, if you depict a regular heating radiator schematically, you might get something like this:

From a layout point of view, this is usually a set of heat exchange sections (item 1). The number of these sections can vary quite a bit wide range. Many battery models allow you to vary this amount, adding or decreasing, depending on the required thermal total power or based on the maximum permissible dimensions of the assembly. To do this, a threaded connection is provided between the sections using special couplings (nipples) with the necessary sealing. Other radiators do not have this possibility; their sections are tightly connected or even form a single metal structure. But in the light of our topic, this difference is not of fundamental importance.

But what is important is the hydraulic part of the battery, so to speak. All sections are united by common collectors located horizontally at the top (item 2) and bottom (item 3). And at the same time, each section provides for the connection of these collectors with a vertical channel (item 4) for the movement of coolant.

Each of the collectors has two inputs, respectively. In the diagram they are designated G1 and G2 for the upper collector, G3 and G4 for the lower.

In the vast majority of connection schemes used in heating systems of private houses, only these two inputs are always used. One is connected to the supply pipe (that is, coming from the boiler). The second is to the “return”, that is, to the pipe through which the coolant returns from the radiator to the boiler room. The remaining two entrances are blocked by plugs or other locking devices.

And what’s important is that the efficiency of the expected heat transfer of the heating radiator largely depends on how these two inputs, supply and return, are mutually located.

Note : Of course, the diagram is given with a significant simplification, and many types of radiators may have their own characteristics. So, for example, in the familiar cast iron batteries of the MS-140 type, each section has two vertical channels connecting the collectors. And in steel radiators there are no sections at all - but the system of internal channels, in principle, repeats the hydraulic circuit shown. So everything that will be said below applies equally to them.

Where is the supply pipe and where is the return pipe?

It is quite clear that in order to correctly optimally position the inlet and outlet to the radiator, it is necessary to at least know in which direction the coolant is moving. In other words, where is the supply and where is the “return”. A fundamental difference may already be hidden in the type of heating system itself - it can be single-pipe or

Features of a single-pipe system

This heating system is especially common in high-rise buildings; it is also quite popular in single-story individual construction. Its wide demand is primarily based on the fact that significantly fewer pipes are required during creation, and the volume of installation work is reduced.

To explain it as simply as possible, this system is one pipe running from the supply pipe to the inlet pipe of the boiler (as an option - from the supply to the return manifold), onto which series-connected heating radiators seem to be “strung”.

On the scale of one level (floor) it might look something like this:

It is quite obvious that the “return” of the first radiator in the “chain” becomes the supply of the next one - and so on, until the end of this closed circuit. It is clear that from the beginning to the end of a single-pipe circuit, the coolant temperature steadily decreases, and this is one of the most significant disadvantages of such a system.

It is also possible to arrange a single-pipe circuit, which is typical for buildings with several floors. This approach was usually practiced in the construction of urban apartment buildings. However, you can also find it in private houses with several floors. This should also not be forgotten if, say, the owners got the house from the old owners, that is, with the heating circuits already installed.

There are two possible options here, shown below in the diagram under the letters “a” and “b”, respectively.

Prices for popular heating radiators

- Option “a” is called a riser with top coolant supply. That is, from the supply manifold (boiler), the pipe rises freely to the highest point of the riser, and then sequentially passes down through all the radiators. That is, the supply of hot coolant directly to the batteries is carried out in the direction from top to bottom.

- Option “b” - single-pipe distribution with bottom supply. Already on the way up, along the ascending pipe, the coolant passes a series of radiators. Then the flow direction changes to the opposite, the coolant passes through another string of batteries until it enters the “return” collector.

The second option is used for reasons of saving pipes, but it is obvious that the disadvantage of a single-pipe system, that is, the temperature drop from radiator to radiator along the coolant flow, is expressed to an even greater extent.

Thus, if you have a single-pipe system installed in your house or apartment, then in order to select the optimal radiator connection diagram, you should definitely clarify in which direction the coolant is supplied.

Secrets of the popularity of the Leningradka heating system

Despite quite significant disadvantages, single-pipe systems still remain quite popular. An example of this is described in detail in a separate article on our portal. And another publication is devoted to that element without which single-pipe systems are not able to operate normally.

What if the system is two-pipe?

A two-pipe heating system is considered more advanced. It is easier to operate and lends itself better to fine adjustments. But this is against the backdrop of the fact that more material will be required to create it, and installation work is becoming more extensive.

As can be seen from the illustration, both the supply and return pipes are essentially collectors to which the corresponding pipes of each radiator are connected. An obvious advantage is that the temperature in the supply pipe-collector is maintained almost the same for all heat exchange points, that is, it almost does not depend on the location of a particular battery in relation to the heat source (boiler).

This scheme is also used in systems for houses with several floors. An example is shown in the diagram below:

In this case, the supply riser is plugged from above, as is the return pipe, that is, they are turned into two parallel vertical collectors.

It is important to understand one nuance correctly here. The presence of two pipes near the radiator does not mean that the system itself is two-pipe. For example, with a vertical layout there may be a picture like this:

This arrangement can mislead an owner who is inexperienced in these matters. Despite the presence of two risers, the system is still single-pipe, since the heating radiator is connected to only one of them. And the second is a riser that provides the upper supply of coolant.

Prices for aluminum radiators

aluminum radiator

It's a different matter if the connection looks like this:

The difference is obvious: the battery is embedded in two different pipes- feed and return. That is why there is no bypass jumper between the inputs - it is completely unnecessary with such a scheme.

There are other two-pipe connection schemes. For example, the so-called collector (it is also called “radial” or “star”). This principle is often resorted to when they try to place all the circuit distribution pipes secretly, for example, under the floor covering.

In such cases, a collector unit is placed in a certain place, and from It already has separate supply and return pipes for each of the radiators. But at its core, it is still a two-pipe system.

Why is all this being said? And besides, if the system is two-pipe, then to select a radiator connection diagram it is important to clearly know which of the pipes is the supply manifold and which is connected to the “return”.

But the direction of flow through the pipes themselves, which was decisive in a single-pipe system, no longer plays a role here. The movement of the coolant directly through the radiator will depend solely on the relative position of the tie-in pipes into the supply and return.

By the way, even in a small house, a combination of both schemes can be used. For example, a two-pipe system is used, however, in a separate area, say, in one of the spacious rooms or in an extension, several radiators connected according to the single-pipe principle are placed. This means that when choosing a connection diagram, it is important not to get confused, and to individually evaluate each heat exchange point: what will be decisive for it - the direction of flow in the pipe or the relative position of the supply and return collector pipes.

If such clarity is achieved, you can select the optimal scheme for connecting radiators to the circuits.

Diagrams for connecting radiators to the circuit and assessing their effectiveness

Everything said above was a kind of “prelude” to this section. Now we will get acquainted with how you can connect radiators to the pipes of the circuit, and which method provides maximum heat transfer efficiency.

As we have already seen, two radiator inputs are activated, and two more are muted. What direction of movement of the coolant through the battery will be optimal?

A few more preliminary words. What are the “motivating reasons” for the movement of coolant through the radiator channels.

- This is, firstly, the dynamic fluid pressure created in the heating circuit. The liquid tends to fill the entire volume if conditions are created for this (there are no air pockets). But it is quite clear that, like any flow, it will tend to flow along the path of least resistance.

- Secondly, the difference in temperature (and, accordingly, density) of the coolant in the radiator cavity itself becomes the “driving force”. Hotter flows tend to rise, trying to displace cooler ones.

The combination of these forces ensures the flow of coolant through the radiator channels. But depending on the connection diagram, the overall picture can vary quite a bit.

Prices for cast iron radiators

cast iron radiator

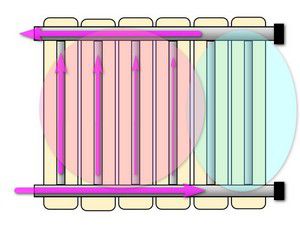

Diagonal connection, top feed

This scheme is considered to be the most effective. Radiators with such a connection show their full capabilities. Usually, when calculating a heating system, it is this that is taken as the “unit”, and for all the others one or another correction reduction factor will be introduced.

It is quite obvious that a priori the coolant cannot encounter any obstacles with such a connection. The liquid completely fills the volume of the upper manifold pipe and flows evenly through vertical channels from the upper to the lower manifold. As a result, the entire heat exchange area of the radiator is heated evenly, and maximum heat transfer from the battery is achieved.

Single-sided connection, top feed

Very widespread diagram - this is how radiators are usually installed in a single-pipe system in the risers of high-rise buildings with top supply, or on descending branches with bottom supply.

In principle, the circuit is quite effective, especially if the radiator itself is not too long. But if there are many sections assembled into a battery, then the appearance of negative aspects cannot be ruled out.

It is quite likely that the kinetic energy of the coolant will be insufficient for the flow to fully pass through the upper collector to the very end. The liquid looks for “easy paths”, and the bulk of the flow begins to pass through the vertical internal channels of the sections, which are located closer to the inlet pipe. Thus, it is impossible to completely exclude the formation of a stagnation area in the “peripheral zone”, the temperature of which will be lower than in the area adjacent to the side of the cut-in.

Even with normal radiator dimensions along the length, you usually have to put up with a loss of thermal power of approximately 3–5%. Well, if the batteries are long, then the efficiency may be even lower. In this case, it is better to use either the first scheme, or use special methods for optimizing the connection - a separate section of the publication will be devoted to this.

Single-sided connection, bottom feed

The scheme cannot be called effective, although, by the way, it is used quite often when installing single-pipe heating systems in multi-storey buildings, if the supply is from below. On the ascending branch, builders will most often install all the batteries in the riser this way. and, probably, this is the only at least somewhat justified case of its use.

Despite all the similarities with the previous one, the shortcomings here only get worse. In particular, the occurrence of a stagnation zone on the side of the radiator away from the inlet becomes even more likely. This is easy to explain. Not only will the coolant look for the shortest and freest path, but the difference in density will also contribute to its upward movement. And the periphery may either “freeze” or the circulation in it will be insufficient. That is, the far edge of the radiator will become noticeably colder.

Loss of heat transfer efficiency with such a connection can reach 20÷22%. That is, it is not recommended to resort to it unless absolutely necessary. And if circumstances leave no other choice, then it is recommended to resort to one of the optimization methods.

Two-way bottom connection

This scheme is used quite often, usually for reasons of hiding the supply pipe from visibility as much as possible. True, its effectiveness is still far from optimal.

It is quite obvious that the easiest path for coolant is the lower collector. Its spread upward through vertical channels occurs solely due to the difference in density. But this flow is hindered by counter flows of cooled liquid. As a result, the upper part of the radiator can warm up much more slowly and not as intensely as we would like.

Losses in the overall efficiency of heat exchange with such a connection can reach up to 10÷15%. True, such a scheme is also easy to optimize.

Diagonal connection with bottom feed

It is difficult to think of a situation in which one would be forced to resort to such a connection. Nevertheless, let's consider this scheme.

Prices for bimetallic radiators

bimetallic radiators

The direct flow entering the radiator gradually wastes its kinetic energy, and may simply not “finish” along the entire length of the lower collector. This is facilitated by the fact that the flows in the initial section rush upward, both along the shortest path and due to the temperature difference. As a result, on a battery with large comic sections, it is quite likely that a stagnant area with a low temperature will appear under the return pipe.

Approximate loss of efficiency, despite the apparent similarity with the most optimal option, with such a connection are estimated at 20%.

Two-way connection from above

Let's be honest - this is more for an example, since applying such a scheme in practice would be the height of illiteracy.

Judge for yourself - a direct passage through the upper manifold is open for liquid. And generally no other incentives for spreading throughout the rest of the radiator volume. That is, only the area along the upper collector will actually heat up - the rest of the area is “outside the game.” It is hardly worth assessing the loss of efficiency in this case - the radiator itself becomes clearly ineffective.

The upper two-way connection is rarely used. Nevertheless, there are also such radiators - distinctly high ones, often simultaneously serving as dryers. And if you have to connect pipes this way, then it is imperative to use various methods to transform such a connection into an optimal scheme. Very often this is already built into the design of the radiators themselves, that is, the upper one-way connection remains so only visually.

How can you optimize the radiator connection diagram?

It is quite understandable that any owners want their heating system to show maximum efficiency with minimal energy consumption. And for this we must try to apply the most optimal insert diagrams. But often the pipework is already there and you don’t want to redo it. Or, initially, the owners plan to lay the pipes so that they become almost invisible. What to do in such cases?

On the Internet you can find many photographs where they try to optimize the insert by changing the configuration of the pipes suitable for the battery. The effect of increasing heat transfer must be achieved, but outwardly some works of such “art” look, frankly, “not very good.”

There are other methods to solve this problem.

- You can purchase batteries that, although outwardly no different from ordinary ones, still have a feature in their design that turns one or another possible connection method into one as close to optimal as possible. A partition is installed in the right place between the sections, which radically changes the direction of movement of the coolant.

In particular, the radiator can be designed for bottom two-way connection:

All the “wisdom” is the presence of a partition (plug) in the lower collector between the first and second sections of the battery. The coolant has nowhere to go, and it rises vertical channel of the first section up. And then, from this upper point, further distribution, quite obviously, already proceeds, as in the most optimal scheme with diagonal connection with feed from above.

Or, for example, the case mentioned above, when both pipes need to be brought from above:

In this example, the baffle is installed on the upper manifold, between the penultimate and last sections of the radiator. It turns out that there is only one path left for the entire volume of coolant - through the lower entrance of the last section, vertically along it - and then into the return pipe. Eventually " route The fluid flow through the battery channels again becomes diagonal from top to bottom.

Many radiator manufacturers think through this issue in advance - whole series go on sale, in which the same model can be designed for different insertion patterns, but in the end the optimal “diagonal” is obtained. This is indicated in the product data sheets. At the same time, it is also important to take into account the direction of the insertion - if you change the flow vector, the entire effect is lost.

- There is another possibility to increase the efficiency of the radiator using this principle. To do this, you should find special valves in specialized stores.

They must correspond in size to the selected battery model. When such a valve is screwed in, it closes the adapter nipple between the sections, and then into it internal thread the supply or return pipe is packed, depending on the design.

- Shown above internal partitions are designed primarily to improve heat transfer when batteries are connected on both sides. But there are ways for one-sided insertion - we're talking about about the so-called flow extenders.

Such an extension is a pipe, usually with a nominal diameter of 16 mm, which is connected to the radiator plug and, when assembled, ends up in the cavity of the manifold, along its axis. On sale you can find such extensions for the required type of thread and the required length. Or you can simply purchase a special coupling, and select a tube of the required length for it separately.

Prices for metal-plastic pipes

metal-plastic pipes

What does this achieve? Let's look at the diagram:

The coolant entering the radiator cavity enters the distant top corner, that is, to the opposite edge of the upper collector. And from here its movement to the outlet pipe will again be carried out according to the optimal “diagonal from top to bottom” pattern.

Many masters They also practice making their own extension cords. If you look at it, there is nothing impossible about it.

It can be used as an extension cord itself metal-plastic pipe for hot water, diameter 15 mm. Will only be left with inside Pack a fitting for metal plastic into the battery passage plug. After assembling the battery, the extension cord of the required length is put into place.

As can be seen from the above, it is almost always possible to find a solution on how to turn an ineffective battery insertion scheme into an optimal one.

What can you say about the one-way bottom connection?

They may ask in bewilderment - why the article has not yet mentioned the diagram of the lower connection of the radiator on one side? After all, it enjoys quite wide popularity, since it allows for hidden pipe connections to the maximum extent.

But the fact is that the possible schemes were considered above, so to speak, from a hydraulic point of view. And in them series of one-way bottom connection there is simply no space - if at one point both the coolant is supplied and taken away, then no flow through the radiator will occur at all.

What is commonly understood under the bottom one-way connection in fact, it only involves connecting pipes to one edge of the radiator. But the further movement of the coolant through the internal channels, as a rule, is organized according to one of the optimal schemes discussed above. This is achieved either by the design features of the battery itself, or by special adapters.

Here is just one example of radiators specifically designed for piping On the one side below:

If you look at the diagram, it immediately becomes clear that the system of internal channels, partitions and valves organizes the movement of the coolant according to the already known principle of “one-way with supply from above,” which can be considered one of the optimal options. There are similar schemes that are also supplemented with a flow extender, and then the most effective “diagonal from top to bottom” pattern is generally achieved.

Even an ordinary radiator can be easily converted into a model with a bottom connection. To do this, purchase a special kit - a remote adapter, which, as a rule, is immediately equipped with thermal valves for thermostatic adjustment of the radiator.

The upper and lower pipes of such a device are packed into the sockets of a conventional radiator without any modifications. The result is a finished battery with a bottom one-sided connection, and even with a thermal regulation and balancing device.

So, we figured out the connection diagrams. But what else can affect the heat transfer efficiency of a heating radiator?

How does its location on the wall affect the efficiency of the radiator?

You can purchase a very high-quality radiator, apply the optimal connection diagram, but in the end you will not achieve the expected heat transfer, if you do not take into account a number of important nuances of its installation.

There are several generally accepted rules for the location of batteries in a room relative to the wall, floor, window sills, and other interior items.

- Most often, radiators are located under window openings. This place is still unclaimed for other objects, and besides this, the flow of heated air becomes a kind of thermal curtain, which largely limits the free spread of cold from the surface of the window.

Of course, this is just one of the installation options, and radiators can also be mounted on walls, regardless of the presence of those window openings– it all depends on the required number of such heat exchange devices.

- If the radiator is installed under a window, then they try to adhere to the rule that its length should be about ¾ the width of the window. This will ensure optimal heat transfer and protection against the penetration of cold air from the window. The battery is installed in the center, with a possible tolerance of up to 20 mm in one direction or another.

- The radiator should not be installed too high - a window sill hanging over it can turn into an insurmountable barrier to rising convection air currents, which leads to a decrease in the overall efficiency of heat transfer. They try to maintain a clearance of about 100 mm (from the top edge of the battery to the bottom surface of the “visor”). If you can’t set the entire 100 mm, then at least ¾ of the radiator thickness.

- There is a certain regulation of clearance from below, between the radiator and the floor surface. A position that is too high (more than 150 mm) can lead to the formation of a layer of air along the floor covering that is not involved in convection, that is, a noticeably cold layer. Too small a height, less than 100 mm, will introduce unnecessary difficulties during cleaning; the space under the battery can turn into an accumulation of dust, which, by the way, will also negatively affect the efficiency of thermal output. Optimal height– within 100÷120 mm.

- The optimal location from load-bearing wall. Even when installing brackets for the battery canopy, take into account that there must be a free gap of at least 20 mm between the wall and the sections. Otherwise, dust deposits may accumulate there and normal convection will be disrupted.

These rules can be considered indicative. If the radiator manufacturer does not give other recommendations, then you should follow them. But quite often, the passports of specific battery models contain diagrams that specify the recommended installation parameters. Of course, then they are taken as the basis for installation work.

The next nuance is how open the installed battery is for complete heat exchange. Of course, the maximum performance will be with a completely open installation on a level vertical surface walls. But, quite understandably, this method is not used so often.

If the battery is located under a window, then the window sill may interfere with the convection air flow. The same, even to a greater extent, applies to niches in the wall. In addition, they often try to cover radiators, or even completely closed them (with the exception of the front grille) with casings. If these nuances are not taken into account when choosing the required heating power, that is, the thermal output of the battery, then you may well be faced with the sad fact that it is not possible to achieve the expected comfortable temperature.

The table below shows the main possible options for installing radiators on the wall according to their “degree of freedom”. Each case is characterized by its own indicator of loss of overall heat transfer efficiency.

| Illustration | Operational features of the installation option |

|---|---|

| The radiator is installed so that nothing overlaps the top, or the window sill (shelf) protrudes no more than ¾ of the thickness of the battery. In principle, there are no obstacles to normal air convection. If the battery is not covered with thick curtains, then there is no interference with direct thermal radiation. In calculations, this installation scheme is taken as a unit. |

| The horizontal “visor” of a window sill or shelf completely covers the radiator from above. That is, a rather significant obstacle appears to the ascending convection flow. With normal clearance (which was already mentioned above - about 100 mm), the obstacle does not become “fatal”, but certain losses in efficiency are still observed. Infrared radiation from the battery remains in full. The final loss of efficiency can be estimated at approximately 3÷5%. |

| A similar situation, but only on top there is not a canopy, but a horizontal wall of a niche. Here the losses are already somewhat greater - in addition to simply the presence of an obstacle to the air flow, some of the heat will be spent on unproductive heating of the wall, which usually has a very impressive heat capacity. Therefore, it is quite possible to expect heat losses of approximately 7 - 8%. |

| The radiator is installed as in the first option, that is, there are no obstacles to convection flows. But on the front side, its entire area is covered with a decorative grille or screen. The intensity of infrared heat flow is significantly reduced, which, by the way, is the determining principle of heat transfer for cast iron or bimetallic batteries. The overall loss of heating efficiency can reach 10÷12%. |

| A decorative casing covers the radiator on all sides. Despite the presence of slots or grilles to ensure heat exchange with the air in the room, both thermal radiation and convection are sharply reduced. Therefore, we have to talk about a loss of efficiency reaching 20–25%. |

So, we examined the basic schemes for connecting radiators to the heating circuit, and analyzed the advantages and disadvantages of each of them. Information was obtained on the methods used to optimize circuits if, for some reason, it is impossible to change them in other ways. Finally, recommendations are provided for placing batteries directly on the wall - indicating the risks of loss of efficiency that accompany selected installation options.

Presumably, this theoretical knowledge will help the reader choose the right scheme based on from the specific conditions for creating a heating system. But it would probably be logical to end the article by providing our visitor with the opportunity to independently evaluate the required heating battery, so to speak, in numerical terms, with reference to a specific room and taking into account all the nuances discussed above.

There is no need to be scared - all this will be easy if you use the offered online calculator. Below you will find the necessary brief explanations for working with the program.

How to calculate which radiator is needed for a particular room?

Everything is quite simple.

- First, the amount of thermal energy required to warm up the room is calculated, depending on its volume, and to compensate for possible heat losses. Moreover, a fairly impressive list of diverse criteria is taken into account.

- Then the resulting value is adjusted depending on the planned radiator insertion pattern and the features of its location on the wall.

- The final value will show how much power a radiator needs to fully heat a particular room. If you purchase a collapsible model, then you can at the same time

If we talk about what comfort in the home primarily depends on, then one of the primary factors will be warmth. It is this that “breathes life” into any building, regardless of whether we are talking about a luxurious house with several floors or a small apartment in an old building. What provides warmth? Naturally, a well-designed heating system. Moreover, in modern conditions it must be not only effective, but also economical, and such a balance is not at all easy to achieve. Although, in principle, nothing is impossible, so on the pages of our website we consistently tell you how to create excellent heating in your home. This time our topic is heating radiator connection diagrams. This is one of the most important points when designing a heating system, which can be implemented in several ways.

What types of heating systems are there?

In order to understand how to connect a heating radiator, you need to clearly understand what system it will be integrated into. Even if all the work is carried out by craftsmen from a specialized company, the owner of the house still needs to know what heating scheme will be implemented in his home.

Single pipe heating

It is based on the supply of water to radiators installed in a multi-story building (usually high-rise buildings). This connection of a heating radiator is the simplest.

However, while installation is accessible, such a scheme has one serious drawback - it is impossible to regulate the heat supply. None special devices such a system does not provide. Therefore, the heat transfer corresponds to the design norm established by the project.

Visual diagrams for connecting radiators for different heating systems: one-pipe and two-pipe

Two-pipe heating

When considering options for connecting heating radiators, it is naturally worth paying attention to the two-pipe heating system. Its operation is based on the supply of hot coolant through one pipe, and the discharge of cooled water in the opposite direction through the second pipe. Implemented here parallel connection heating devices. The advantage of this connection is the uniform heating of all batteries. In addition, the intensity of heat transfer can be adjusted by a valve that is mounted in front of the radiator.

Important! Correct connection heating radiators implies compliance with the requirements of the main regulatory document - SNiP 3.05.01-85.

Choosing a radiator installation location: what is the importance?

Regardless of whether the heating radiators are connected in series or in parallel, the functional purpose of these devices is not only to heat the room. By means of batteries, a certain protection (screen) is created from the penetration of cold from the outside. This is precisely what explains the location of the batteries under the window sills. With this distribution of radiators in places of greatest heat loss, that is, in the area of window openings, an effective thermal curtain is created.

There simply cannot be a battery in this place. With its help, a barrier is created to the cold air from the street

Before considering ways to connect heating radiators, it is necessary to draw up a diagram of the location of these devices. It is important to determine the correct installation distances for radiators, which will ensure their maximum heat transfer. So, the heating batteries are absolutely correctly positioned if:

- lowered from the bottom of the window sill by 100 mm;

- are located at a distance of 120 mm from the floor;

- spaced from the wall at a distance of 20 mm.

Coolant circulation methods

As you know, water, and it is usually what is poured into the heating system, can circulate forcibly or naturally. The first option involves using a special water pump that pushes water through the system. Naturally, this element is included in the general heating scheme. And in most cases it is installed either near the heating boiler, or is already a structural element of it.

A natural circulation system is very relevant in places where there are frequent power outages. The circuit does not include a pump, and the heating boiler itself is non-volatile. Water moves through the system due to the fact that the heated column of water displaces the cold coolant. How the connection of radiators will be implemented under such circumstances depends on many factors, including the need to take into account the characteristics of the heating main and its length.

Any of the four connection methods can be implemented if there is a circulation pump in the heating system

So, let's look at these options in more detail.

Method No. 1 - one-way connection

Connecting the battery in this way involves installing an inlet pipe (supply) and an outlet pipe (return) to the same section of the radiator:

This ensures uniform heating of all sections of each individual battery. A one-way heating system is a rational solution in one-story houses, if you plan to install radiators with a large number of sections (about 15). However, if the accordion has more sections, then significant heat loss will occur, which means it is worth considering another connection option.

Method No. 2 - bottom and saddle connection

Relevant in those systems where the heating pipeline is hidden under the floor. In this case, both the coolant supply pipe and the outlet pipe are mounted to the lower pipes of the opposing sections. The weak point of connecting batteries this way is low efficiency, since in percentage terms heat loss can reach 15%. Logically, the radiators in the upper part heat up unevenly.

Method No. 3 - cross (diagonal) connection

This option is designed for connecting batteries with a large number of sections to the heating system. Thanks to special design The coolant is evenly distributed inside the radiator, which ensures maximum heat transfer.

Direction of coolant movement during cross connection (1-Maevsky tap; 2-plug; 3-heating radiator; 4-directional coolant movement)

The answer to the question of how to properly connect a heating battery in such a situation is extremely simple: supply - from above, return - from below, but from different sides. When radiators are connected diagonally, heat loss does not exceed 2%.

We tried to cover the topic of possible connection diagrams for heating radiators in as much detail as possible. We hope you will be able to evaluate all the pros and cons of each of the options described, and choose the most relevant one in your particular case.

Methods for connecting heating radiators - possible diagrams and options

The most common heating radiator connection diagrams are proposed in this article. You will learn what determines the correct connection of heating radiators and how to do it correctly.

Connecting heating radiators, wiring diagrams, installation of batteries

Any heating system is a rather complex “organism” in which each of the “organs” performs a strictly assigned role. And one of the most important elements are heat exchange devices - they are entrusted with the final task of transferring thermal energy to the premises of the house. In this capacity, conventional radiators, open or open convectors can act hidden installation, water underfloor heating systems that are gaining popularity are pipe circuits laid in accordance with certain rules.

Connecting heating radiators, wiring diagrams, installation of batteries

This publication will focus on heating radiators. Let us not be distracted by their diversity, structure and specifications: on our portal there is enough comprehensive information on these topics. Now we are interested in another set of questions: connecting heating radiators, wiring diagrams, installation of batteries. Correct installation heat exchange devices, rational use the technical capabilities inherent in them are the key to the efficiency of the entire heating system. Even the most expensive modern radiator will have low returns if you do not listen to the recommendations for its installation.

What should you consider when choosing radiator piping schemes?

How does a heating radiator work?

If you take a simplified look at most heating radiators, their hydraulic design is a fairly simple, understandable diagram. These are two horizontal collectors that are connected to each other by vertical jumper channels through which the coolant moves. This entire system is either made of metal, which provides the necessary high heat transfer (a striking example is cast iron batteries), or is “clad” in a special casing, the design of which allows for maximum contact area with air (for example, bimetallic radiators).

Very simplified - diagram of the design of most heating radiators

1 – Upper collector;

2 – Lower collector;

3 – Vertical channels in radiator sections;

4 – Heat exchange housing (casing) of the radiator.

Both collectors, upper and lower, have outputs on both sides (respectively, in the diagram, the upper pair B1-B2, and the lower pair B3-B4). It is clear that when connecting a radiator to the heating circuit pipes, only two of the four outputs are connected, and the remaining two are muted. And the operating efficiency of the installed battery largely depends on the connection diagram, that is, on the relative position of the coolant supply pipe and the return outlet.

And first of all, when planning the installation of radiators, the owner must understand exactly what kind of heating system is operating or will be created in his house or apartment. That is, he must clearly understand where the coolant is coming from and in which direction its flow is directed

Single pipe heating system

In multi-storey buildings, a single-pipe system is most often used. In this scheme, each radiator is, as it were, inserted into a “break” in a single pipe through which both the coolant is supplied and its discharge towards the “return” is carried out.

Options for single-pipe heating risers in a multi-storey building.

The coolant passes sequentially through all the radiators installed in the riser, gradually wasting heat. It is clear that in the initial section of the riser its temperature will always be higher - this must also be taken into account when planning the installation of radiators.

One more point is important here. Such a one-pipe system apartment building can be organized according to the principle of top and bottom feed.

- On the left (item 1) the top supply is shown - the coolant is transferred through a straight pipe to top point riser, and then sequentially passes through all the radiators on the floors. This means that the flow direction is from top to bottom.

- In order to simplify the system and save consumables, another scheme is often organized - with bottom feed (item 2). In this case, radiators are installed in the same series on the pipe ascending to the upper floor as on the pipe going down. This means that the direction of coolant flow in these “branches” of one loop changes to the opposite. Obviously, the temperature difference in the first and last radiator of such a circuit will be even more noticeable.

It is important to understand this issue - on which pipe of such a single-pipe system is your radiator installed - the optimal insertion pattern depends on the direction of flow.

A mandatory condition for piping a radiator in a single-pipe riser is a bypass

The name “bypass”, which is not entirely clear to some, is understood as a jumper connecting the pipes connecting the radiator to the riser in single pipe system. What is it needed for bypass in the heating system, what rules are followed when installing it - read in the special publication of our portal.

The single-pipe system is also widely used in private one-story houses, if only for reasons of saving materials for its installation. In this case, it is easier for the owner to figure out the direction of the coolant flow, that is, from which side it will flow into the radiator, and from which side it will exit.

In any single-pipe heating system, when installing radiators, it is important to know exactly the direction of coolant flow

Advantages and disadvantages of a single-pipe heating system

While attractive due to the simplicity of its design, such a system is still somewhat alarming due to the difficulty of ensuring uniform heating on different radiators in the house wiring. What is important to know about single-pipe heating system for a private house How to install it yourself - read in a separate publication on our portal.

Two-pipe system

Already based on the name, it becomes clear that each of the radiators in such a scheme “rests” on two pipes – separately on the supply and “return”.

If you look at the two-pipe wiring diagram in a multi-story building, you will immediately see the differences.

Both risers act as unique collectors, to which heating radiators are connected in parallel, independently of each other.

It is clear that the dependence of the heating temperature on the location of the radiator in the heating system is minimized. The direction of flow is determined only by the relative position of the pipes embedded in the risers. The only thing you need to know is which specific riser serves as the supply and which is the “return” - but this, as a rule, is easily determined even by the temperature of the pipe.

Some apartment residents may be misled by the presence of two risers, in which the system will not cease to be one-pipe. Look at the illustration below:

There are two risers in both cases, and the heating systems are fundamentally different

On the left, although there seem to be two risers, a single-pipe system is shown. The coolant is simply supplied from the top through one pipe. But on the right is a typical case of two different risers - supply and return.

Dependence of the efficiency of the radiator on the scheme of its insertion into the system

Why was all that said? what is posted in previous sections articles? But the fact is that the heat transfer of the heating radiator very seriously depends on the relative position of the supply and return pipes.

Connecting heating radiators, wiring diagrams, installation of batteries - consider in order

Connecting heating radiators, piping diagrams, installation of batteries is a set of questions that often arises for homeowners. Let's try to deal with them in order.

Connection diagrams for heating radiators in a private house - installation rules and regulations

In order for an autonomous type heating system to work as efficiently and efficiently as possible, it is important not only to correctly select the heating devices included in its design, but also to connect them appropriately, using optimal connection diagrams for heating radiators in a private home.

In order for an autonomous type heating system to work as efficiently and efficiently as possible, it is important not only to correctly select the heating devices included in its design, but also to connect them appropriately, using optimal connection diagrams for heating radiators in a private home.

The comfort of living in the house directly depends on how competently and professionally this is done, so it is best to entrust the calculations and installation of the system to specialists. But, if necessary, you can perform the installation work yourself, paying attention to the following points:

- Correct wiring installation.

- The sequence of connecting all elements of the system, including pipelines, shut-off and control valves, boiler and pumping equipment.

- Choosing the optimal heating equipment and components.

Selecting the connection location and installation norm

Before connecting a heating radiator in a private home, you must familiarize yourself with the following standards for the installation and placement of these devices:

- The distance from the bottom of the battery to the floor is 10-12 cm.

- The gap from the top of the radiator to the window sill is at least 8-10 cm.

- The distance from the back panel of the device to the wall is at least 2 cm.

Important: Failure to comply with the above standards may lead to a decrease in heat transfer levels heating devices and incorrect operation of the entire heating system.

Installing heating radiators in a private house in a niche or using a screen affects heat loss

Installing heating radiators in a private house in a niche or using a screen affects heat loss

Another important point, which is worth considering before installing heating radiators in a private house: their location in the premises. It is considered optimal when they installed under windows. In this case they create additional protection from the cold entering the house through window openings.

Please note that in rooms with several windows, it is better to install radiators under each of them, connecting them in sequential order. IN corner rooms It is also necessary to install several heating sources.

Radiators connected to the system must have an automatic or manual heating control function. For this purpose, they are equipped with special thermostats designed to select the optimal temperature regime depending on the operating conditions of these devices.

Types of pipe routing

Connecting heating radiators in a private house can be done using one-pipe or two-pipe scheme.

The first method is widely used in multi-storey buildings, in which hot water is first supplied through a supply pipe to the upper floors, after which, after passing through radiators from top to bottom, it enters the heating boiler, gradually cooling. Most often, in such a scheme there is natural circulation of coolant.

The photo shows a single-pipe diagram for connecting a radiator in an apartment with a bypass (jumper)

The photo shows a single-pipe diagram for connecting a radiator in an apartment with a bypass (jumper)

- Low cost and material consumption.

- Relatively easy to install.

- System compatibility heated floors and radiators of various types.

- Possibility of installation in rooms with different layouts.

- Aesthetic appearance due to the use of only one pipe.

- Difficulty in carrying out hydro- and heat calculations.

- The inability to regulate the heat supply on a separate radiator without affecting the others.

- High level of heat loss.

- Necessary high blood pressure heat carrier.

Please note: During operation of a single-pipe heating system, difficulties may arise with the circulation of coolant through the pipeline. However, they can be solved by installing pumping equipment.

Installation of heating radiators in a private house with single-pipe wiring using a circulation pump

Installation of heating radiators in a private house with single-pipe wiring using a circulation pump

Two-pipe scheme Connecting heating batteries in a private house is based on the parallel method of connecting heating devices. That is, the branch that supplies the coolant is supplied to the system is in this case not connected with the branch along which it returns, and their connection is made at the end point of the system.

- Possibility of using automatic temperature controllers.

- Ease of maintenance. If necessary, shortcomings and errors made during installation can be corrected without damaging the system.

- Higher cost of installation work.

- Longer installation period compared to single-pipe wiring.

The diagram shows an example of a two-pipe heating distribution

The diagram shows an example of a two-pipe heating distribution

Radiator connection options

To know how to properly connect a heating battery, you need to take into account that in addition to the types of pipeline wiring, there are several schemes for connecting batteries to the heating system. These include the following options for connecting heating radiators in a private home:

In this case, the connection of the outlet and supply pipes is made on one side of the radiator. This connection method allows you to achieve uniform heating of each section when minimum costs for equipment and a small volume of coolant. Most often used in multi-storey buildings, with a large number of radiators.

Useful information: If a battery connected to the heating system in a one-way circuit has a large number of sections, the efficiency of its heat transfer will significantly decrease due to weak heating of its remote sections. It is better to ensure that the number of sections does not exceed 12 pieces. or use another connection method.

- Diagonal (cross).

Used when connecting heating devices with a large number of sections to a system. In this case, the supply pipe, just like in the previous connection option, is located at the top, and the return pipe is at the bottom, but they are located on opposite sides of the radiator. Thus, heating the maximum area of the battery is achieved, which increases heat transfer and improves the efficiency of heating the room.

This connection diagram, otherwise called “Leningradka”, is used in systems with hidden pipeline, laid under the floor. In this case, the connection of the inlet and outlet pipes is made to the lower branch pipes of the sections located at opposite ends of the battery.

The disadvantage of this scheme is heat loss, reaching 12-14%, which can be compensated by installing air valves designed to remove air from the system and increase battery power.

Heat loss depends on the choice of radiator connection method

Heat loss depends on the choice of radiator connection method

For quick dismantling and repair of the radiator, its outlet and inlet pipes are equipped with special taps. To regulate power, it is equipped with a temperature control device, which is installed on the supply pipe.

You can find out what technical characteristics aluminum heating radiators have in a separate article. In it you will also find a list of popular manufacturing companies.

You can find out what technical characteristics aluminum heating radiators have in a separate article. In it you will also find a list of popular manufacturing companies.

And about what it is expansion tank for closed type heating, read another article. Volume calculation, installation.

Tips for choosing an instantaneous water heater for your tap can be found here. Device, popular models.

As a rule, installation of the heating system and installation of heating radiators is carried out by invited specialists. However, using the listed methods for connecting heating radiators in a private house , You can install the batteries yourself, strictly observing technological sequence this process.

If you carry out this work accurately and competently, ensuring the tightness of all connections in the system, there will be no problems with it during operation, and installation costs will be minimal.

The photo shows an example of a diagonal method of installing a radiator in a country house

The photo shows an example of a diagonal method of installing a radiator in a country house

The procedure will be as follows:

- Dismantling old radiator(if necessary), having previously closed the heating main.

- We mark the installation site. Radiators are fixed to brackets that need to be attached to the walls, taking into account regulatory requirements, described earlier. This must be taken into account when marking.

- We attach the brackets.

- Assembling the battery. To do this, we install adapters on the mounting holes available in it (included with the device).

Attention: Usually two adapters have a left-hand thread, and two - a right-hand thread!

- To plug unused collectors we use Mayevsky taps and stop caps. To seal connections we use sanitary linen, winding it on the left thread counterclockwise, on the right thread clockwise.

- We screw the ball valves to the connection points with the pipeline.

- We hang the radiator in place and connect it to the pipeline with mandatory sealing of the connections.

- We carry out pressure testing and test run of water.

Thus, before connecting a heating battery in a private house, you need to decide on the type of wiring in the system and its connection diagram. In this case, installation work can be performed independently, taking into account established standards and process technology.

Connection diagrams for heating radiators in a private house: how to connect the battery correctly, options

Using rational schemes for connecting heating radiators in a private house, you can not only achieve the maximum efficient work systems, but also save on heating costs.

Types of piping, or how to properly connect a heating battery

Providing heat to a house or apartment is task number one during the cold season. Therefore, every average person strives first to create an efficiently operating system that would be economically justified. And since most heating systems are of the radiator type, the question of how to properly connect heating batteries is one of the most pressing.

For many, this means nothing, especially for those who are faced with the problem of piping the heating system for the first time. But anyone who has already dealt with the creation of such schemes understands perfectly what we are talking about.

There are not so many classifications of types of piping and routing of a pipe system, especially when it comes to radiator piping. Therefore, it will not be very difficult to understand this issue. Most often, it is the pipe layout that influences the nature of the connection of battery radiators. Therefore, it is necessary to consider the classification of various heating systems and determine which of them is best suited for a particular connection.

Classification of heating systems

The main criterion for dividing heating systems is the number of circuits. Based on this criterion, all heating systems are divided into two groups:

- Single-pipe.

- Two-pipe.

The first option is the simplest and cheapest. This is essentially a ring from boiler to boiler, with heating radiators installed in between. If it comes to a one-story building, then this is a justified option in which you can use the natural circulation of the coolant. But in order for the temperature to be uniform in all rooms of the house, it is necessary to take some measures. For example, build up sections on the outermost radiators in the chain.

The best option for such a pipe circuit is to connect the battery using the Leningrad method. In essence, it turns out that ordinary pipe passes through all the rooms near the floor, and radiator radiators crash into it. In this case, the so-called bottom cut is used. That is, the radiator is connected to the pipe through two lower pipes - the coolant enters one and exits from the other.

Attention! Heat loss with this type of battery connection is 12–13%. This is the highest level of heat loss. So before making such a decision, weigh the pros and cons. Initial savings can turn into large expenses during operation.

In general, this is a good connection scheme that justifies itself in small buildings. And in order to evenly distribute the coolant over all radiators, you can install it in circulation pump. The investment is inexpensive, and the device works perfectly and requires little power consumption. But it ensures uniform heat distribution throughout all rooms.

By the way, a single-pipe piping scheme is very often used in city apartments. True, the bottom battery connection cannot be used here. The same should be said about two-pipe system.

Other types of connection

There are more profitable options than the bottom connection, which reduce heat loss:

- Diagonal. All experts have long come to the conclusion that this type of connection is ideal regardless of the piping scheme in which it is used. The only system where this type cannot be used is a horizontal bottom single-pipe system. That is, the same Leningrad woman. What is the essence of a diagonal connection? The coolant moves diagonally inside the radiator - from the top to the bottom pipe. It turns out that hot water is evenly distributed throughout the entire internal volume of the device, falling from top to bottom, that is, naturally. And since the speed of water movement is not very high during natural circulation, the heat transfer will be high. Heat loss in this case is only 2%.

- Lateral, or one-sided. This type is very often used in apartment buildings. The connection is made to the side pipes on one side. Experts believe that this type is one of the most effective, but only if the system has coolant circulation under pressure. There are no problems with this in city apartments. And to provide it in a private house, you will have to install a circulation pump.

What is the advantage of one type over others? In fact, correct connection is the key to effective heat transfer and reduced heat loss. But in order to connect the battery correctly, you need to prioritize.

Take, for example, a two-story a private house. What to prefer in this case? Here are several options:

Two and one pipe systems

- Install a one-pipe system with side connection.

- Install a two-pipe system with a diagonal connection.

- Use a single-pipe scheme with lower wiring on the first floor and upper wiring on the second.

So you can always find options for connection diagrams. Of course, you will have to take into account some nuances, for example, the location of the premises, the presence of a basement or attic. But in any case, it is important to correctly distribute the radiators among the rooms, taking into account the number of their sections. That is, the power of the heating system will have to be taken into account even with such an issue as the correct connection of radiators.

In a one-story private house, connecting the battery correctly will not be very difficult, given the length of the heating circuit. If this is a single-pipe Leningrad circuit, then only a lower connection is possible. If it is a two-pipe scheme, then you can use a collector system or a solar one. Both options are based on the principle of connecting one radiator to two circuits - coolant supply and return. In this case, top pipe distribution is most often used, where distribution along the circuits is carried out in the attic.

By the way, this option is considered optimal both in terms of operation and during the repair process. Each circuit can be disconnected from the system without turning off the latter. To do this, a shut-off valve is installed at the point where the pipes are separated. Exactly the same one is mounted after the radiator on the return pipe. You just have to close both valves to cut off the circuit. After draining the coolant, you can safely carry out repairs. In this case, all other circuits will operate normally.

Many people believe that the radiator connection option is not that important when it comes to heat dissipation. After all, much will depend on the type of heat source chosen. For example, at bimetallic radiators heating, heat transfer is higher than that of cast iron. But imagine that cast iron devices are installed according to the diagonal principle of coolant movement, and bimetallic ones are installed along the bottom. In the first case, heat loss is 2%, and in the second - 12%. The difference in losses is as much as 10%. For a heating system, this is a fairly high indicator, which will affect not only temperature regime indoors, but also on the amount of fuel consumed. This is very important for private houses.

Today, experts give recommendations regarding increasing the heat transfer of devices. To do this, you can install a reflective panel on the wall behind the radiator, for example, a regular piece of fiberboard trimmed with aluminum foil. But keep in mind that the distance from the wall to the radiator in this case should be at least 1.5 cm.

Conclusion on the topic

What is the conclusion? Correct connection of heating radiators is an important criterion for the effective operation of the entire system. Not only the temperature inside the rooms, but also fuel consumption will depend on this. And savings today have become the main indicator on which the well-being of every resident of apartments and private houses depends.

How to properly connect a heating battery - professional advice

The question of how to properly connect a heating battery is one of the most pressing today. Not everyone understands that the connection diagram affects the comfort of living due to the correct distribution of heat throughout the rooms. And this, in turn, determines savings.

Any heating system is a rather complex “organism” in which each of the “organs” performs a strictly assigned role. And one of the most important elements is heat exchange devices - they are entrusted with the final task of transferring thermal energy to the premises of the house. This role can be provided by conventional radiators, convectors of open or hidden installation, and increasingly popular water floor heating systems - pipe circuits laid in accordance with certain rules.

You might be interested in information about what it is

This publication will focus on heating radiators. We will not be distracted by their diversity, design and technical characteristics: our portal contains enough comprehensive information on these topics. Now we are interested in another set of questions: connecting heating radiators, wiring diagrams, installation of batteries. Correct installation of heat exchange devices, rational use of the technical capabilities inherent in them is the key to the efficiency of the entire heating system. Even the most expensive modern radiator will have low returns if you do not listen to the recommendations for its installation.

What should you consider when choosing radiator piping schemes?

If you take a simplified look at most heating radiators, their hydraulic design is a fairly simple, understandable diagram. These are two horizontal collectors that are connected to each other by vertical jumper channels through which the coolant moves. This entire system is either made of metal, which provides the necessary high heat transfer (a striking example -), or is “clad” in a special casing, the design of which provides for a maximum contact area with air (for example, bimetallic radiators).

1 – Upper collector;

2 – Lower collector;

3 – Vertical channels in radiator sections;

4 – Heat exchange housing (casing) of the radiator.

Both collectors, upper and lower, have outputs on both sides (respectively, in the diagram, the upper pair B1-B2, and the lower pair B3-B4). It is clear that when connecting a radiator to the heating circuit pipes, only two of the four outputs are connected, and the remaining two are muted. And the operating efficiency of the installed battery largely depends on the connection diagram, that is, on the relative position of the coolant supply pipe and the return outlet.

And first of all, when planning the installation of radiators, the owner must understand exactly what kind of heating system is operating or will be created in his house or apartment. That is, he must clearly understand where the coolant is coming from and in which direction its flow is directed.

Single pipe heating system

In multi-storey buildings, a single-pipe system is most often used. In this scheme, each radiator is, as it were, inserted into a “break” in a single pipe through which both the coolant is supplied and its discharge towards the “return” is carried out.

The coolant passes sequentially through all the radiators installed in the riser, gradually wasting heat. It is clear that in the initial section of the riser its temperature will always be higher - this must also be taken into account when planning the installation of radiators.

One more point is important here. Such a single-pipe system of an apartment building can be organized according to the principle of upper and lower supply.

- On the left (item 1) the top supply is shown - the coolant is transferred through a straight pipe to the top point of the riser, and then sequentially passes through all the radiators on the floors. This means that the flow direction is from top to bottom.

- In order to simplify the system and save consumables, another scheme is often organized - with bottom feed (item 2). In this case, radiators are installed in the same series on the pipe ascending to the upper floor as on the pipe going down. This means that the direction of coolant flow in these “branches” of one loop changes to the opposite. Obviously, the temperature difference in the first and last radiator of such a circuit will be even more noticeable.

It is important to understand this issue - on which pipe of such a single-pipe system is your radiator installed - the optimal insertion pattern depends on the direction of flow.

A mandatory condition for piping a radiator in a single-pipe riser is a bypass

The name “bypass,” which is not entirely clear to some, refers to a jumper connecting the pipes connecting the radiator to the riser in a single-pipe system. Why it is needed, what rules are followed when installing it - read in the special publication of our portal.

The single-pipe system is also widely used in private one-story houses, if only for reasons of saving materials for its installation. In this case, it is easier for the owner to figure out the direction of the coolant flow, that is, from which side it will flow into the radiator, and from which side it will exit.

Advantages and disadvantages of a single-pipe heating system

While attractive due to the simplicity of its design, such a system is still somewhat alarming due to the difficulty of ensuring uniform heating on different radiators in the house wiring. Read what is important to know about how to install it yourself in a separate publication on our portal.

Two-pipe system

Already based on the name, it becomes clear that each of the radiators in such a scheme “rests” on two pipes – separately on the supply and “return”.

If you look at the two-pipe wiring diagram in a multi-story building, you will immediately see the differences.

It is clear that the dependence of the heating temperature on the location of the radiator in the heating system is minimized. The direction of flow is determined only by the relative position of the pipes embedded in the risers. The only thing you need to know is which specific riser serves as the supply and which is the “return” - but this, as a rule, is easily determined even by the temperature of the pipe.

Some apartment residents may be misled by the presence of two risers, in which the system will not cease to be one-pipe. Look at the illustration below:

On the left, although there seem to be two risers, a single-pipe system is shown. The coolant is simply supplied from the top through one pipe. But on the right is a typical case of two different risers - supply and return.

Dependence of the efficiency of the radiator on the scheme of its insertion into the system

Why was all that said? what is posted in the previous sections of the article? But the fact is that the heat transfer of the heating radiator very seriously depends on the relative position of the supply and return pipes.

| Scheme of inserting a radiator into the circuit | Coolant flow direction |

|---|---|

| Diagonal two-way radiator connection, with supply from above | |

|  |

| This scheme is considered the most effective. In principle, it is this that is taken as the basis when calculating the heat transfer of a specific radiator model, that is, the power of the battery for such a connection is taken as one. The coolant, without encountering any resistance, completely passes through the upper collector, through all vertical channels, ensuring maximum heat transfer. The entire radiator heats up evenly over its entire area. | |

|  |