External walls, and together with the rest of the building structures, if necessary and depending on the specifics of the building solution, natural-climatic and engineering-geological conditions of construction, are dissected expansion joints various types:

- temperature,

- sedimentary,

- seismic.

An expansion joint is used to reduce stress on various elements structures in places of possible deformations that occur during seismic phenomena, temperature fluctuations, uneven soil settlement, as well as other influences that can cause their own loads that reduce the bearing capacity of the structure.

This is a cut in the structure of a building that divides the structure into separate blocks, thereby imparting a degree of elasticity to the structure. For sealing, it is filled with elastic insulating material.

Expansion joints are used depending on the purpose. These are temperature, antiseismic, sedimentary and shrinkage. Expansion joints divide the building into compartments, from ground level to the roof inclusive. This does not affect the foundation, which is located below ground level, where it experiences less temperature fluctuations, and therefore is not subject to significant deformation.

Some parts of the building may have different number of floors. Then the foundation soils, which are located under different parts of the building, perceive different loads. This can lead to cracks in the walls of the building, as well as in other structures.

Also, the uneven settlement of soils at the base of a structure can be influenced by differences in the composition and structure of the base within the building area. This can cause sedimentary cracks to appear even in a building of the same number of storeys, over a considerable length.

To avoid dangerous deformations, sedimentary joints. They differ in that when cutting a building along its entire height, the foundation is also included. Sometimes, if necessary, stitches are used different types. They can be combined into temperature-sediment joints.

In buildings constructed in earthquake-prone areas, anti-seismic joints are used. Their peculiarity is that they divide the building into compartments, which from a structural point of view are independent stable volumes.

In the walls that are built from monolithic concrete various types, shrinkage seams are made. As concrete hardens, monolithic walls decrease in volume. The seams themselves prevent the occurrence of cracks, which reduce the load-bearing capacity of the walls.

Expansion joint- designed to reduce loads on structural elements in places of possible deformations that occur when air temperature fluctuates, seismic phenomena, uneven soil settlement and other influences that can cause dangerous self-loads that reduce the load-bearing capacity of structures. It is a kind of cut in the structure of a building, dividing the structure into separate blocks and, thereby, giving the structure a certain degree of elasticity. For sealing purposes, it is filled with elastic insulating material.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

Expansion joints divide the building into compartments from ground level to the roof inclusive, without affecting the foundation, which, being below ground level, experiences temperature fluctuations to a lesser extent and, therefore, is not subject to significant deformations. The distance between expansion joints is taken depending on the wall material and design winter temperature construction area.

Individual parts of the building may have different heights. In this case, the foundation soils located directly under different parts of the building will bear different loads. Uneven soil deformation can lead to cracks in walls and other building structures. Another reason for uneven settlement of the foundation soils may be differences in the composition and structure of the foundation within the building area. Then, in buildings of considerable length, even with the same number of storeys, sedimentary cracks may appear. To avoid the occurrence of dangerous deformations in buildings, sedimentary joints are installed. These seams, unlike temperature seams, cut buildings along their entire height, including foundations.

If it is necessary to use expansion joints of different types in one building, they are combined, if possible, in the form of so-called temperature-sedimentation joints.

Anti-seismic seams used in buildings constructed in areas prone to earthquakes. They cut the building into compartments, which from a structural point of view should represent independent stable volumes. Along the lines of anti-seismic seams, double walls or double rows of load-bearing racks are placed, which are part of the load-bearing frame system of the corresponding compartment.

Shrink seams made in walls built from various types of monolithic concrete. Monolithic walls decrease in volume as concrete hardens. Shrinkage joints prevent the occurrence of cracks that reduce the load-bearing capacity of the walls. During hardening monolithic walls the width of the shrinkage joints increases; Once the shrinkage of the walls is complete, the seams are tightly sealed.

Various materials are used to organize and waterproof expansion joints:

- sealants

- putty

- waterstops

Expansion joint- a vertical gap filled with elastic material that divides the walls of the building. Its purpose is to prevent the appearance of cracks from temperature changes and uneven settlement of the building.

|

|

|

Expansion joints in buildings and their external walls: |

|

Temperature shrinkage seams arranged to avoid the formation of cracks and distortions in the walls caused by the concentration of forces from the effects of variable air temperatures and shrinkage of materials (masonry, concrete). Such seams are cut only ground part building.

To avoid the appearance of cracks caused by shrinkage deformations in walls made of monolithic concrete and concrete stones, as well as uncured sand-lime brick(up to three months of age) it is recommended to lay structural reinforcement with a total cross-section of 2-4 cm2 for each floor along the perimeter of the building at the level of window sills and lintels.

The seams in walls connected to metal or reinforced concrete structures must coincide with the seams in the structures.

Maximum permissible distances (in m) between expansion joints in the walls of heated buildings

| Estimated winter outside temperature(in degrees) | Masonry of baked bricks, ceramics and large blocks of all types on grade mortars | Masonry of sand-lime bricks and ordinary concrete stones on brand mortars | Masonry from natural stones on brand solutions | ||||||

| 100-50 | 25-10 | 4 | 100-50 | 25-10 | 4 | 100-50 | 25-10 | 4 | |

| below - 30 | 50 | 75 | 100 | 25 | 35 | 50 | 32 | 44 | 62 |

| from 21 to - 30 | 60 | 90 | 120 | 30 | 45 | 60 | 38 | 56 | 75 |

| from 11 to - 20 | 80 | 120 | 150 | 40 | 60 | 80 | 50 | 75 | 100 |

| from 10 and above | 100 | 150 | 200 | 50 | 75 | 100 | 62 | 94 | 125 |

The distances indicated in the table are subject to reduction: for walls of closed unheated buildings - by 30%, for open stone structures - by 50%

With changes in temperature, reinforced concrete structures are deformed: they are shortened or lengthened, and due to concrete shrinkage they are shortened. When the foundation settles unevenly in the vertical direction, parts of the structures are mutually displaced.

Reinforced concrete structures, as a rule, are statically indeterminate systems, in which, with temperature changes, the development of shrinkage deformations and uneven settlement of foundations, additional forces arise that can cause the formation of cracks. To reduce this kind of effort in long buildings, temperature-shrinkage and settlement joints are necessary.

Reinforced concrete structures, as a rule, are statically indeterminate systems, in which, with temperature changes, the development of shrinkage deformations and uneven settlement of foundations, additional forces arise that can cause the formation of cracks. To reduce this kind of effort in long buildings, temperature-shrinkage and settlement joints are necessary.

In the coverings and floors of buildings, the distance between the seams depends on the flexibility of the columns and the pliability of the joints; V monolithic structures this distance should be less than in prefabricated ones. When installing rolling supports, thermal stresses can be completely avoided.

In addition, the distance between expansion joints depends on the temperature difference; therefore, in heated buildings these distances, regardless of all other factors, are smaller.

Temperature-shrinkage seams cut through structures from the roof to the foundations, and settlement seams completely separate one part of the structure from another. A temperature-shrinkage joint can be formed by installing paired columns on a common foundation. Settlement joints are provided in places where there is a sharp difference in the height of buildings, where newly erected buildings adjoin old ones when constructing buildings or structures on soils of different composition, and in other cases when uneven settlement of foundations is possible.

Sedimentary seams also form by constructing paired columns, but installed on separate foundations.

|

|

|

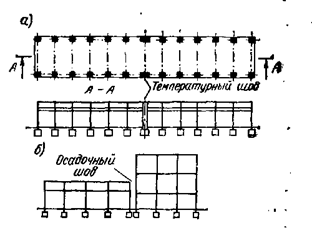

Expansion joints: a - the building is divided by an expansion joint; b - the building is divided by a sedimentary seam |

Expansion joints: 1 - expansion joint; 2 - sedimentary seam; 3 - inset span of sedimentary seam |

Distances between temperature-shrinkage joints in concrete and iron concrete structures Low structures can be accepted constructively, without calculations.

|

|

|

Installation of sedimentary (expansion) joints along the perimeter of the building envelope: 1 – entrance group; 2 – decorative blind area; 3 decorative path made of floor stones; 4 – lawn; 5 – semi-closed drainage; 6 – blind area made of monolithic concrete; 7 – expansion joints with wooden fillings (short boards); 8 – wall of the house; 9 – semi-closed (open) drainage in the form of a tray; 10 – sedimentary (deformation) seam between the base of the house and the foundation entrance group; 11 - windows |

|

|

|

|

|

General view of the structure of the sedimentary (deformation) seam along section 1-1: 1 – pebbles (crushed stone, sand); semi-closed drainage (cut asbestos cement pipe) persistent flat stones; 4 – pre-compacted foundation soil; 5 - sand cushion height from 8 to 15 cm; 6 – layer of pebbles or crushed stone 5-10 cm; 7 – short board; 8 – closed bypass drainage pipe; 9 – bedded stone-lounger; 10 - basement part building; 11 – foundation; 12- compacted base; 13 possible level of elevation groundwater; 14 – blind area made of monolithic concrete. End of form |

|

Sedimentary seams divide the building lengthwise into parts to prevent structural destruction in case of possible uneven settlement individual parts. Sedimentary seams run from the eaves of the building to the base of the foundation; the location of the seams is indicated in the project. The seams in the walls are made in the form of tongue and groove, usually 1/2 brick thick, with two layers of roofing felt; and in foundations - without tongue and groove. A gap of 1-2 bricks is left above the top edge of the foundation under the tongue and groove of the wall, so that when settling the tongue and groove does not rest against the foundation masonry. Otherwise, the masonry may collapse in this place. Sedimentary seams in foundations and walls are caulked with tarred tow.

Sedimentary seams divide the building lengthwise into parts to prevent structural destruction in case of possible uneven settlement individual parts. Sedimentary seams run from the eaves of the building to the base of the foundation; the location of the seams is indicated in the project. The seams in the walls are made in the form of tongue and groove, usually 1/2 brick thick, with two layers of roofing felt; and in foundations - without tongue and groove. A gap of 1-2 bricks is left above the top edge of the foundation under the tongue and groove of the wall, so that when settling the tongue and groove does not rest against the foundation masonry. Otherwise, the masonry may collapse in this place. Sedimentary seams in foundations and walls are caulked with tarred tow.

To superficial groundwater did not penetrate into the basement through the sedimentary seam, with its outside arrange clay castle or apply other measures provided for by the project. Expansion joints protect buildings from cracks due to temperature deformations.

Sedimentary joints are installed at the junctions of building sections:

- located on heterogeneous soils;

- attached to existing buildings;

- with a difference in height exceeding 10 m;

- in all cases where uneven settlement of the foundation can be expected.

Sedimentation and expansion joints in brick walls should be made in the form of a tongue and groove with a groove size for walls with a thickness of 1.5 and 2 bricks - 13 x 14 cm, and for thicker walls 13 x 27 cm. In rubble masonry of basement walls and foundations, the seams can be arranged through.

When installing expansion joints of the coating It is best to tear the roofing carpet. Rolled rubber can be used as a vapor barrier membrane in the construction of an expansion joint.

|

|

|

Expansion joint |

Scheme for installing a deformation-settlement joint between sections of the retaining wall |

In cases where the expansion joint is installed in watershed areas, and the movement of water flow along the seam is impossible, or the slopes on the roof are more than 15%, then it is permissible to use a simplified construction of the expansion joint. The deformations of the building are compensated by the upper mineral wool insulation.

In roofs with a base made of corrugated sheets, it is necessary to secure the main layers roofing material at the edges expansion joint.

Temperature-deformation seam with walls made of lightweight concrete or piece materials can be installed in roofs with concrete base or from reinforced concrete slabs.

|

|

|

Simplified expansion joint design |

Expansion joint in roofs with a corrugated sheet base |

The wall of the expansion joint is installed on the supporting structures. The edge of the TDS wall should be 300 mm higher than the surface of the roofing carpet. The seam between the walls must be at least 30 mm.

A metal expansion joint installed in a temperature expansion joint cannot serve as a vapor barrier. It is necessary to lay additional layers of vapor barrier material on the compensator.

Temperature seam installed in long walls to avoid the appearance of cracks due to temperature changes. Such a seam cuts the structures only from the ground part, to the foundations, because foundations being in the ground do not experience temperature effects. The distance between these seams ranges from 20 to 200 m and depends on the material of the walls and the area of construction. The smallest seam width is 20 mm.

|

|

| Construction of a temperature expansion joint in the partitions of the building: 1 - masonry of small cellular concrete blocks; 2, 3 - cellular concrete floor slabs; 4 - seam with thermal insulation board(the presence of debris in the seam is unacceptable wall material and glue); 5 - seam in the foundation; 6 — reinforced belt along the perimeter of the building; 7 - reinforced concrete base slab; 8 - reinforced belt around the perimeter of the building with external thermal insulation; 9 - roof with thermal insulation according to the rules roofing works | Vertical expansion joint: 1 - external facing slabs; 2 — hydro-wind-protective layer; 3 - plaster system; 19 — profile for a vertical expansion joint; 23 - racks wooden frame; 30 - insulating material |

Sedimentary seam cuts the building to its full height - from the ridge to the base of the foundation. Such a seam is placed depending on several factors:

when the difference in building heights is not less than 10 m;

if the soils used as a foundation have different bearing capacities;

during the construction of buildings with different construction periods.

The smallest joint width is 20 mm

Seismic seam arranged in buildings that are being built in seismic areas.

Scheme of placement and design of expansion joints: a – facade of the building; b – expansion or sedimentation seam with groove and tongue; c – temperature or sedimentation joint in a quarter; d – expansion joint with compensator; 1 – expansion joint; 2 – sedimentary seam; 3 – wall; 4 – foundation; 5 – insulation; 6 – compensator; 7 – roll insulation.

The designs of expansion joints must ensure the possibility of moving the ends of the spans without overstressing and damage to the elements of the seam, the riding clothes, the canvas and the spans; must be water- and dirt-proof (prevent water and dirt from getting on the ends of the beams and support platforms); operable in specified temperature ranges; have reliable anchoring in the span of the structure; prevent the penetration of moisture onto the roadway slab and under the edging (have reliable waterproofing).

The designs of expansion joints must ensure the possibility of moving the ends of the spans without overstressing and damage to the elements of the seam, the riding clothes, the canvas and the spans; must be water- and dirt-proof (prevent water and dirt from getting on the ends of the beams and support platforms); operable in specified temperature ranges; have reliable anchoring in the span of the structure; prevent the penetration of moisture onto the roadway slab and under the edging (have reliable waterproofing).

The material of construction of expansion joints must withstand wear, abrasion and abrasion, the effects of ice, snow, sand; should be relatively immune to the effects of sunlight, oil products, and salts.

In general, expansion joints should be located:

- between the foundation and wall masonry using bitumen roll materials;

- between warm and cold walls;

- when the wall thickness changes;

- in unreinforced walls more than 6 m long (longitudinal reinforcement of walls makes it possible to increase the distance between expansion joints);

- when crossing long load-bearing walls;

- at junctions with columns or structures made of other materials;

- in places sudden change wall height.

Sealing expansion joints

Expansion joints are sealed mineral wool or polyethylene foam. On the room side, the seams are sealed with elastic, vapor-tight materials, with outside– weatherproof sealants or flashings. Facing material should not overlap the expansion joint.

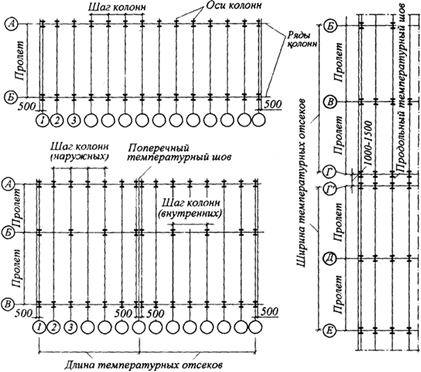

The dimensions of temperature blocks are taken depending on the type and design of buildings. Longest distances(m) between expansion joints in frame buildings, which can be allowed without verification calculations.

In addition to temperature deformations, a building can give uneven settlement if it is located on heterogeneous soils or in the case of sharply different operating loads along the length of the building. In this case, to avoid sedimentary deformations, arrange sedimentary joints. In this case, the foundations are made independent, and in the above-ground part of the building the sedimentary seam is combined with a temperature seam or with an abutment seam (the abutment of buildings of different heights, an old building to a new one). Expansion joints arranged in walls and coverings in order to ensure the possibility of mutual displacement of adjacent parts of the building in both horizontal and vertical directions without violating the thermal resistance of the seam and its waterproofing properties.

When installing longitudinal expansion joints or differences in heights of parallel spans on paired columns, paired modular coordination axles with an insert between them should be provided. Depending on the size of the columns in each of the adjacent spans, the dimensions of the inserts between paired coordination axes along the lines of expansion joints in buildings with spans of the same height and with coverings of rafter beams(trusses) are taken equal to 500, 750, 1000 mm.

|

|

|

Linking columns and walls one-story buildings To coordinate axes: a – binding of columns to the middle axes; b, c – the same, columns and walls to the outer longitudinal axes; d, e, f - the same, to the transverse axes at the ends of buildings and places of transverse expansion joints; g, h, i - connection of columns in longitudinal expansion joints of buildings with spans of the same height; k, l, m - the same, when there is a difference in heights of parallel spans, n, o - the same, when the spans are mutually perpendicular to each other; p, p, s, t – binding of load-bearing walls to the longitudinal coordinate axes; 1 – columns of elevated spans; 2 – columns of lower spans, which are adjacent to the ends of the elevated transverse span |

|

The size of the insert between the longitudinal coordination axes along the line of difference in heights of parallel spans in buildings with roofing on rafter beams (trusses) must be a multiple of 50 mm:

- binding to the coordination axes of the faces of the columns facing the direction of the drop;

- the thickness of the wall made of panels and a gap of 30 m between its internal plane and the edge of the high-span columns;

- a gap of at least 50 mm between the outer plane of the wall and the edge of the low-span columns.

In this case, the size of the insert must be at least 300 mm. The dimensions of the inserts at the junction of mutually perpendicular spans (lower longitudinal to higher transverse) range from 300 to 900 mm. If there is a longitudinal seam between spans that are adjacent to a perpendicular span, this seam is extended into the perpendicular span, where it will be a transverse seam. In this case, the insertion between the coordination axes in the longitudinal and transverse seams is equal to 500, 750 and 1000 mm, and each of the paired columns along the line of the transverse seam must be shifted from the nearest axis by 500 mm. If coating structures are supported on external walls, then the internal plane of the wall is shifted inward from the coordination axis by 150 (130) mm.

Columns are tied to the middle longitudinal and transverse coordination axes of multi-story buildings so that the geometric axes of the columns' sections coincide with the coordination axes, with the exception of columns along the lines of expansion joints. In the case of tying columns and external walls made of panels to the extreme longitudinal coordination axes of buildings, the outer edge of the columns (depending on the frame design) is shifted outward from the coordination axis by 200 mm or aligned with this axis, and a gap of 30 is provided between the inner plane of the wall and the edges of the columns mm. Along the line of transverse expansion joints of buildings with prefabricated ribbed or smooth floors hollow core slabs provide paired coordination axes with an insert between them measuring 1000 mm, and the geometric axes of paired columns are combined with the coordination axes.

In the case of an extension of multi-story buildings to one-story buildings, it is not allowed to mutually mix the coordination axes perpendicular to the extension line and common to both parts of the interconnected building. The dimensions of the insert between the parallel extreme coordination axes along the building extension line are assigned taking into account the use of standard wall panels- extended regular or additional ones.

If there are double walls at expansion joints, double modular alignment axes are used, the distance between which is taken to be equal to the sum of the distances from each axis to the corresponding wall face with the addition of the seam size.

Consider the following regulatory requirements.

SP 15.13330.2012 STONE AND REINFORCED STONE STRUCTURES

Updated editionSNiP II-22-81*

9.78 Temperature shrinkage seams in the walls of masonry buildings should be installed in places of possible concentration of temperature and shrinkage deformations, which can cause masonry breaks, cracks, distortions and shifts of masonry at the seams that are unacceptable under operating conditions (at the ends of extended reinforced and steel inclusions, as well as in places where walls are significantly weakened by holes or openings). The distances between should be established by calculation.

9.79 Maximum distances between temperature-shrinkable seams, which can be taken for unreinforced external walls without calculation:

a) for above-ground stone and large-block walls of heated buildings with the length of reinforced concrete and steel inclusions (lintels, beams, etc.) not exceeding 3.5 m and the width of the partitions not less than 0.8 m - according to Table 33; if the length of inclusions is more than 3.5 m, the masonry sections at the ends of the inclusions must be checked by calculation for strength and crack opening;

b) the same for walls made of rubble concrete - according to table 33 as for masonry made of concrete stones on mortar grade 50 with a coefficient of 0.5;

c) the same, for multilayer walls - according to table 33 for the material of the main structural layer of the walls;

d) for walls of unheated masonry buildings and structures for the conditions specified in “a” - according to table 33 multiplied by coefficients:

for closed buildings and structures - 0.7;

for open structures - 0.6;

e) for stone and large-block walls of underground structures and foundations of buildings located in the zone of seasonal soil freezing - according to Table 33 with a doubling; for walls located below the limit of seasonal soil freezing, as well as in the permafrost zone, without length restrictions.

9.80 Expansion joints in walls connected to reinforced concrete or steel structures, must coincide with the seams in these structures. If necessary, depending on the structural layout of the buildings, additional wall masonry should be provided expansion joints without cutting seams in these places of reinforced concrete or steel structures.

Table 33

| Average outside air temperature of the coldest five-day period | Distance between expansion joints, m, when laying | |||

| from ceramic bricks and stones incl. large-format, natural stones, large blocks of concrete or ceramic bricks | from sand-lime brick, concrete stones, large blocks of sand-lime concrete and sand-lime brick | |||

| on brand solutions | ||||

| 50 or more | 25 or more | 50 or more | 25 or more | |

| Minus 40 °C and below | 50 | 60 | 35 | 40 |

| » 30 °C | 70 | 90 | 50 | 60 |

| » 20 °C and above | 100 | 120 | 70 | 80 |

| Notes

1 For intermediate values of design temperatures, the distances between expansion joints may be determined by interpolation. 2 Distances between temperature-shrinkable seams large-panel buildings made of brick panels are assigned in accordance with. |

||||

9.81 Settlement joints in walls must be provided in all cases where uneven settlement of the base of a building or structure is possible.

9.82 Expansion and settlement seams should be designed with a tongue or groove filled with elastic gaskets, eliminating the possibility of blowing through the seams.

9.84 Vertical expansion joints in the front layer of multi-layer external non-load-bearing walls (including the filling of frames) should be assigned based on temperature and humidity influences, insolation and solar radiation from the condition of ensuring the strength and crack resistance of the masonry, subject to the requirements specified in Appendix D.

Distances between vertical expansion joints and their position must be assigned in the project, taking into account the instructions in Appendix D and the design requirements for the spacing of their location.

The thickness of the seam should be at least 10 mm; elastic gaskets and weather-resistant mastics should be used to fill the seam.

Requirements for the construction of expansion joints

D.4 Horizontal joints are installed in load-bearing multilayer walls with a middle layer of effective insulation - in the facing brick layer, in non-load-bearing walls - along the entire thickness of the wall.

Horizontal expansion joints in the inner and outer layers of non-load-bearing multi-layer walls should be made at the level supporting structures(between the overlying structure and the top row of masonry).

D.5 Horizontal joints along the height of the building in the cladding of load-bearing multi-layer walls with a middle layer of effective thermal insulation can be arranged as follows:

the first seam is under the ceiling of the 2nd floor;

D.6. Vertical expansion joints are installed in the front layer of multilayer external walls, separated from the main layer of insulation.

D 7. Featured maximum distances between vertical expansion joints for straight sections of walls 6 - 7 m. Vertical joints at the corners of the building should be placed at a distance of 250 - 500 mm from the corner on one side. With a facing layer thickness of 250 mm, the distance between the seams can be increased.

If it is necessary to increase the distance between expansion joints it is required to carry out calculations of temperature deformations taking into account design features walls, building structure, its orientation to the cardinal directions and climatic conditions.

Expansion joint

Expansion joint- designed to reduce loads on structural elements in places of possible deformations that occur when air temperature fluctuates, seismic phenomena, uneven soil settlement and other influences that can cause dangerous self-loads that reduce the load-bearing capacity of structures. It is a kind of cut in the structure of a building, dividing the structure into separate blocks and, thereby, giving the structure a certain degree of elasticity. For sealing purposes, it is filled with elastic insulating material.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

Expansion joints divide the building into compartments from ground level to the roof inclusive, without affecting the foundation, which, being below ground level, experiences temperature fluctuations to a lesser extent and, therefore, is not subject to significant deformations. The distance between expansion joints is taken depending on the material of the walls and the estimated winter temperature of the construction area.

Individual parts of the building may have different heights. In this case, the foundation soils located directly under different parts of the building will bear different loads. Uneven soil deformation can lead to cracks in walls and other building structures. Another reason for uneven settlement of the foundation soils may be differences in the composition and structure of the foundation within the building area. Then, in buildings of considerable length, even with the same number of storeys, sedimentary cracks may appear. To avoid the occurrence of dangerous deformations in buildings, sedimentary joints are installed. These seams, unlike temperature seams, cut buildings along their entire height, including foundations.

If it is necessary to use expansion joints of different types in one building, they are combined, if possible, in the form of so-called temperature-sedimentation joints.

Anti-seismic joints are used in buildings constructed in areas prone to earthquakes. They cut the building into compartments, which from a structural point of view should represent independent stable volumes. Along the lines of anti-seismic seams, double walls or double rows of load-bearing racks are placed, which are part of the load-bearing frame system of the corresponding compartment.

Shrinkage joints are made in walls built from various types of monolithic concrete. Monolithic walls decrease in volume as concrete hardens. Shrinkage joints prevent the occurrence of cracks that reduce the load-bearing capacity of the walls. During the hardening process of monolithic walls, the width of the shrinkage joints increases; Once the shrinkage of the walls is complete, the seams are tightly sealed.

Various materials are used to organize and waterproof expansion joints:

- sealants

- putty

- waterstops

Links

- Expansion joints of buildings

- Bridge expansion joints

Wikimedia Foundation. 2010.

Every structural element of a building carries a certain force load during its work in the structure. Moreover, it is not always associated with seismic vibrations or the weight of the building as such. The problem of building physics itself has long been an uneven expansion different materials when heated and their narrowing when cooling.

Eg:

The thermal expansion coefficients of metal and wood differ several times. This justifies mechanical destruction wooden beams located in the cold under-roof space, which are secured using conventional studs and fittings without thermal break. To solve this and some other problems, the construction of expansion joints is used in general construction practice.

Below we present full list problems when this element “works” and helps maintain the structural integrity of the entire building:

- seismic activity of the earth's crust;

- soil settlement, rise of groundwater;

- force deformations;

- sudden change in ambient temperature.

Depending on the nature of the problem being solved, all expansion joints are divided into temperature, shrinkage, seismic and sedimentary.

Temperature expansion joint

Structurally expansion joint is a section that divides the entire structure into sections. The size of the sections and the direction of division - vertical or horizontal - is determined design solution and power calculation of static and dynamic loads.

To seal the cuts and reduce the level of heat loss through expansion joints, they are filled with an elastic heat insulator, most often these are special rubberized materials. Thanks to this separation, the structural elasticity of the entire building increases and the thermal expansion of its individual elements does not have a destructive effect on other materials.

As a rule, a temperature expansion joint runs from the roof to the very foundation of the house, dividing it into sections. It makes no sense to divide the foundation itself, since it is located below the depth of soil freezing and does not experience this negative impact like the rest of the building. The spacing of expansion joints will be influenced by the type of used building materials And geographical location object that determines the average winter temperature.

In statically indeterminate systems reinforced concrete buildings and structures, in addition to the forces from external loads, additional forces arise as a result of temperature changes and concrete shrinkage. In order to limit the magnitude of these forces, temperature-shrinkage seams are installed, the distances between which are determined by calculation.

The calculation may not be done for structures of the 3rd category of crack resistance at design low temperatures outside air above minus 40° C, if the distances between expansion joints do not exceed the required values given in the SNiP table. In any case, the distances between the seams must be no more than:

150 m for heated buildings made of prefabricated structures;

90 m - for heated buildings made of prefabricated monolithic and monolithic structures.

For unheated buildings and structures, the indicated values must be reduced by at least 20%. To prevent the occurrence of additional forces in case of uneven settlements of the base (sections of different heights, difficult soil conditions, etc.), provision is made for the installation of settlement joints.

It should be noted that sedimentary seams cut through the structure to the base, and temperature-shrinkage seams only to the top of the foundations. Sedimentary seams at the same time play the role of temperature-shrinkage seams.

Schemes of expansion joints

The width of the temperature-shrinkable seam is usually 2...3 cm, it is specified by calculation depending on the length of the temperature block and the temperature difference.

Key points in the temperature calculation problem

Expert opinion.

Uncertainty with the rigidity characteristics of the base in the horizontal direction - for example, given the rate at which the thermal load is applied, a fair amount of rheology may occur. Friction on the ground will vary depending on various areas foundation depending on the pressure on the soil in these areas. Local damage to waterproofing - can it happen and should it be taken into account? What about local zones of plasticity in soils? Well, the plus I mentioned backfilling. Variation of the rigidity characteristics of the base in the horizontal direction can repeatedly change the forces from temperature loads. With piles it is even more difficult.

Nonlinearity of reinforced concrete, its rather “long-term” rigidity characteristics - what will be the change in the deformation diagram of reinforced concrete at a loading rate that is characteristic of temperature loads? I am already silent about all the other subtleties of modeling the nonlinear properties of reinforced concrete - at a minimum, it is necessary to model with solids in order to take into account the reduction, including the shear stiffness of all elements, especially massive ones, which are concentrators.

Uncertainty with the temperature loads themselves. In reinforced concrete, even without these loads, numerous cracks will open, and even more so taking into account the temperature. And not only the rigidity of the frame will decrease, but also the loads themselves, because the area of the elements itself decreases (due to the formation of cracks), which is not taken into account by the methods known to me.

Thus, I believe that a full-fledged temperature calculation of reinforced concrete frames is currently a guess, and the only thing you need to trust is design experience, reflected in particular in the recommended distances between temperature blocks.

Settlement expansion joint

Second important application expansion joints is compensation for uneven pressure on the ground during the construction of buildings of varying number of storeys. In this case, the higher part of the building (and, accordingly, heavier) will press on the ground with greater force than the lower part. As a result, cracks can form in the walls and foundation of the building. Similar problem There may also be soil settlement within the area under the foundation of the building.

To prevent cracking of the walls in these cases, sedimentary expansion joints are used, which, unlike the previous type, divide not only the building itself, but also its foundation. Often in the same building there is a need to use different types of seams. Combined expansion joints are called temperature-sedimentary joints.

Antiseismic expansion joints

As their name suggests, such seams are used in buildings located in seismic zones of the Earth. The essence of these seams is to divide the entire building into “cubes” - compartments that are themselves stable containers. Such a “cube” should be limited by expansion joints on all sides, along all edges. Only in this case will the anti-seismic seam work.

Along the anti-seismic seams, double walls or double rows of support columns are installed, which form the basis load-bearing structure each individual compartment.

Shrinkage expansion joint

Shrinkage expansion joints are used in monolithic concrete frames, since concrete, when hardening, tends to slightly decrease in volume due to the evaporation of water. The shrinkage seam prevents the occurrence of cracks that impair the bearing capacity of the monolithic frame.

The point of such a seam is that it expands more and more, parallel to the hardening of the monolithic frame. After hardening is complete, the resulting expansion joint is completely caulked. To impart hermetic resistance to shrinkage and any other expansion joints, special sealants and waterstops are used.

Problem:

Very often, Customers are faced with the question of initializing the type of seam in building structure through which water flows. Indeed, this issue is very serious and requires certain construction knowledge.

I propose to take a closer look at deformation sedimentary and temperature (“cold”) seams and understand the difference between them.

What is an expansion joint?

Expansion joint - designed to reduce loads on structural elements in places of possible deformations that occur when air temperature fluctuates, seismic phenomena, uneven soil settlement and other influences that can cause dangerous self-loads that reduce the load-bearing capacity of structures. It is a kind of cut in the structure of a building, dividing the structure into separate blocks and, thereby, giving the structure a certain degree of elasticity. For sealing purposes, it is filled with elastic insulating material.

Depending on the purpose, the following expansion joints are used: temperature, sedimentary, anti-seismic and shrinkage.

What is a temperature “cold” seam?

A “cold” concreting joint is the weakest point of a concrete structure, which is formed as a result technological features production monolithic works. That is, during the construction of a building, a monolithic foundation slab is first poured, and then the walls are supported on it. In the same way on finished walls support monolithic ceiling. We consider seams from the point of view of probable leaks, and here it is necessary to mention that there are many technologies for waterproofing such seams.

What are the dangers of seam leaks?

Leaks in expansion joints are not dangerous - there are no important structural elements, but leaks in “cold” seams are a cause for concern, since they contain load-bearing reinforcement that is subject to corrosion. Reducing the diameter of reinforcement by tenths of a millimeter has a very serious impact on bearing capacity. Consequently, “cold” concreting joints require repair and strengthening through injection work.

How to fix leaks?

Practice shows that at the construction stage, work to seal the seams is either not carried out (not counting the polystyrene foam installed) or is carried out extremely poorly! Already at the stage of preparing the object for delivery, widespread leaks of seams appear, which will not allow the construction project to be handed over to the State. commissions!

In such situations, the most EFFECTIVE, FAST and CHEAP method– INJECTION WATERPROOFING from SK LLC “Vertical”

Is it possible to perform injection waterproofing yourself?

It is possible, but on one condition: that you already have extensive experience working with polymer compounds. It is also necessary to take into account a very complex and often very lengthy stage preparatory work, where it is necessary to apply the most non-standard technical solutions that... Another feature is the ability to work with vacuum pump, since the thing is extremely expensive and requires periodic complex Maintenance, up to its complete disassembly and reassembly.

Based on all of the above, it remains to conclude that it is most convenient and cheapest for Customers to contact a specialized company for injection waterproofing, such as "Vertical".

! Most effective solution the problem of leakage of expansion joints is injection waterproofing!

The main advantage of injection waterproofing is guaranteed positive result , which can be observed already in the first minutes after completion of injection waterproofing work.

MAIN ADVANTAGES OF INJECTION WATERPROOFING JOINTS:

High speed of work - a team of 4 specialists per shift can perform waterproofing up to 10 m.p. expansion joint

There is no need for preparatory work that requires approval from government agencies or owners of neighboring buildings - all work is carried out from the side of the premises (from the basement)

Low cost of the work package, since there is no expensive preparation stage

There is no seasonal factor, since work can be performed by local heating of the structure

Stages of work:

1. Main stages of work - SEALING THE EXPANSION JOINT

1) Visual inspection, local opening of the seam, checking and clarification of accepted technical solutions

2) Clearing the expansion joint

3) Placement of the Vilaterm cord in the designed position

4) Installation of injection packers - MC-Injekt

5) Preparing the injection gel for use MC-Injekt GL95 TX

6) Supply of injection gel MC-Injekt GL95 TX with a two-component pneumatic pump (for example, MC-I 700)

2. Main stages of work - SEALING THE "COLD" SEAM

1) Visual inspection, local opening of the seam, verification and clarification of the adopted technical solutions

2) Sealing the expansion joint

3) Installation of injection packers - MC-Injekt

5) Preparation of injection material for use - MC-Injekt 2300, MC-Injekt 2300Top or MC-Injekt2700 *

6) Supply of injection material with a pneumatic pump (for example, MS-I 510 or MS-I 700)

7) Quality control of work performed

* the type of material used is determined depending on the type of seam leakage.

Important! Carrying out injection waterproofing work requires extensive experience in this area and does not forgive mistakes, since the cost of equipment and injection materials quite high.