Tandoor oven - multifunction device. And most importantly, not only specialists can build it. Self-construction of the furnace is also possible.

What is tandoor

- A tandoor is a large clay cauldron, turned upside down, with a small hole in the bottom.

- Clay part of the oven with outside lined with brick, and the space between the brick and the edge of the vessel is filled with clay, sand or salt. They help retain heat in.

- The design of this one is such that there should be a hole in its lower part for blowing.

How it works

For such a stove, a small amount of fuel is enough - firewood or branches. In Asia, saxaul is most often used for kindling. It is placed at the bottom, set on fire and allowed to burn down to coals. After the wood has burned out, you can start baking bread or cooking.

During kindling, all the heat is absorbed by the walls - both of the clay cauldron, and of the peculiar layer, and brick wall. Once heated, the oven begins to give off heat. This ensures long-lasting, uniform temperatures for excellent cooking, both baking and simmering.

What is needed for construction

In order to make such a stove, you will need:

- bricks – refractory and facing;

- sand;

- clay;

- cement;

- grate.

A real tandoor is made from slightly different materials, but modern conditions The listed components are best suited for this.

Assembly technology

Initially, the type of tandoor is selected - ordinary (ground) or earthen, horizontal or vertical. The most common ovens are vertical.

The technology for ground or earth type assembly is different.

The ground structure is built as follows:

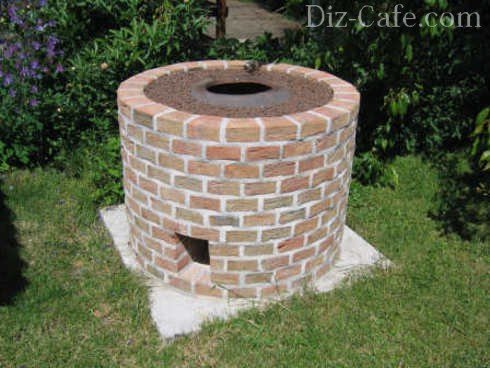

Construction of a vertical tandoor photo:

Video

Another option for building a tandoor is presented in the video:

The earthen tandoor is assembled as follows:

- It is necessary to prepare a pit for the furnace, based on the fact that the height will be 1.2 m plus the foundation. The bottom, or foundation, is laid out of brick in one layer. An asbestos-cement pipe is connected to the prepared foundation, which is a kind of blower. The edge of the pipe should be located among the bricks of the first row.

- The top of the masonry must be covered with clay. The tandoor is assembled in a similar way, except for the outer lining with brick. The soil will act here as a facing.

The walls of the furnace itself must be laid out of refractory bricks, with the bricks shifted inward to form an upper cone-shaped dome. The outside of the masonry should be coated with clay, and after it dries, the space between the soil and the walls should be carefully filled with clay and sand. The oven must also be hardened by fire.

Construction earthen tandoor photo:

Such stoves are widespread among the peoples of Central Asia. They differ from other designs in shape: in appearance they resemble a jug with a wide bottom and smooth walls that taper at the top.

The unusual geometry and special properties of the material make it possible to accumulate heat in the walls of the oven, which is used for cooking various dishes. Most often they fry in it meat dishes(kebabs), bake various types flatbreads, preparing pilaf. The walls have the same temperature over the entire height, so there are no such troubles as an unevenly baked dish.

The original stove, made using ancient technologies, is made only from clay, dried in the sun and fired over a fire of saxaul wood. It can be easily built in Central Asia, but it is impossible to create in our latitudes. The reason is the lack of conditions for dehydration of the material.

So that the furnace walls acquire necessary qualities, requires very low humidity, a certain light spectrum, and high firing temperature. Under such conditions, there are no internal stresses or cracks in them. It is impossible to completely remove moisture from clay in our conditions; it remains in large quantities even in a dry wall. Water begins to evaporate intensively during firing, which leads to the appearance of cracks on the surface, worsening the heat-storing properties of the structure.

Therefore, far from Central Asia, modified tandoors are built, for example, from bricks, which are covered from the inside with clay mortar. They are much thicker than traditional clay ones and require more fuel to heat up, but in mid-latitudes there are no problems with firewood. Of all the types of brick tandoors, the best are those built from fireclay blocks, which after heat treatment acquire the properties of ceramics.

A brick tandoor is used as follows:

- Light a fire inside the oven and maintain it until the walls reach a high temperature. All this time it accumulates heat.

- After burning the wood, wait until the walls have cooled to a temperature of 250 degrees.

- Place the food inside and cover the opening with a lid. Clay bricks hold high temperature long enough and ensure the preparation of several bookmarks of dishes.

How to make a tandoor from brick

To build a furnace with heat-concentrating properties, perform the work in a certain sequence and choose the right construction material. Let's take a closer look at each stage.

Selection of materials

To build a brick tandoor with your own hands, you will need special fireproof fireclay materials - brick and clay.

Fireclay blocks are made from a clay-fireclay mixture. There are several types of this building material, differing in density and fire resistance. For our case, samples marked ША, ШБ are suitable. Bricks are produced in three standard sizes: 230:113:65 mm, 250:123:65 mm and 300:150:65 mm. Due to the large dimensions of the blocks, there are fewer gaps in the walls, which makes it easy to obtain a smooth surface.

Fireclay blocks are more expensive than ordinary silicate ones, so in order not to overpay, make a drawing of a brick tandoor, from which you can determine their exact quantity.

Choose a material for the stove good quality, paying attention to some points. Suitable samples have an attractive appearance sandy color and grainy base. When tapped, they make a metallic sound, and after impact they break into large pieces. Unfired bricks crumble into crumbs, and the sound after tapping on them is dull; it is impossible to build stoves from such blocks - they do not retain heat, have low strength, so the structure may simply fall apart.

Before purchasing, make sure that the material was stored in a dry place, as... it absorbs moisture well, after which it loses 75 percent of its qualities. When using outdoors, take measures to protect the structure from precipitation.

Fireclay bricks can withstand high temperatures, so silicate or ceramic samples cannot be placed together with them. Over time, a wall made of a combined material will simply collapse.

For the same reason, do not use a regular sand-cement mixture to fasten the elements. For such purposes, a special heat-resistant solution is intended - martel. It is made from crushed fireclay bricks and clay. The mixture has increased strength and adhesion, which will allow it to be applied with a thickness of no more than 1 mm.

You can prepare the masonry mortar yourself from fireclay clay, which is sold dry in construction stores. Available for sale in 20 kg bags. One package is enough to lay 20-30 bricks. To build 1 m 3 of wall you will need 5 bags of material. When purchasing, make sure that the powder has not yet expired and that it was stored in a dry place. Wet material loses its quality.

Other substances are also added to the mixture to change its properties. For example, to reduce the setting time add special means, which are combined with fireclay - cement, salt or liquid glass. Quartz sand is added to the solution if it is too liquid.

Preparation of mortar for masonry and plastering

To prepare the solution yourself you will need fireclay clay, salt and quartz sand in a ratio of 4:1:1. An ordinary mixture based on clay and sand quickly becomes covered with cracks and does not adhere well to the brick. The prepared composition is very plastic and sets quickly and does not peel off during operation.

The solution is mixed as follows:

- Pour a bag of fireclay powder and all components into a deep container and fill with water until it covers the substance.

- Leave the solution for 2-3 days (check the instructions included with the substance), stirring occasionally.

- At the end of the period, mix everything again and check the viscosity of the contents of the container. It should resemble thick sour cream. If the mixture is too thin, add sand, if thick, add water.

- To reduce the hardening time, add cement to it, no more than 2 kg per 20 kg of powder. Instead of cement, you can add ordinary salt at the rate of 100-150 g per bucket of mortar or liquid glass in an amount of 1-3 percent of the volume of the mixture.

- The amount of solution must be calculated in advance in order to use it before hardening.

Construction of the tandoor base

The stove is built on a solid foundation, which prevents cracks from appearing on the walls during seasonal soil movement. Therefore, before building a brick tandoor, study its composition. Rocky and sandy soil is considered the most favorable. For safety reasons, the structure must be located at a distance of at least 3 m from buildings and plants.

On heaving and clayey soils for a tandoor oven, it is necessary to cast a reinforced foundation, for example, a columnar one. In other cases, you can get by with a light base in the form monolithic slab.

To make a foundation, perform the operations in the following sequence:

- Draw a 120x120 cm square on the ground to fit the oven standard sizes. Inside, dig a hole 10 cm deep, and along the perimeter select soil to a depth of 15 cm. In the corners of the pit, use a drill to dig holes 70 cm deep, 12-15 cm in diameter. Pour sand into the holes in a layer of 10-15 cm.

- Install reinforcement welded into a quadrangle into the holes and fill it with concrete, while it should rise 5 cm above the bottom. Concrete protrusion can be ensured using formwork. The solution is prepared from sand, cement and gravel, which are taken in a ratio of 3:1:1. Gravel fractions should not exceed 1 cm. Choose cement no lower than PC-400. After the concrete has hardened, remove the formwork and fill the bottom with sand flush with the concrete belt around the perimeter of the pit. Compact the loose mass and fill it with water.

- Prepare the formwork for the monolithic slab, ensuring that it protrudes 10-15 cm above the ground.

- Weld a reinforcing mesh with 15-20 cm cells and place it in the pit. It is made from rods with a diameter of 10-12 mm. The rods do not need to be welded, but tied together at the intersections with annealed wire. It will be ideal if it is at a depth of 5 cm from the surface of the slab.

- Fill the hole with concrete and check the levelness of the surface, wait 2-3 weeks for the solution to harden.

- The base of the product is a circle, so on the prepared area, draw a circle with a diameter of 75 cm, this is the most popular size of a brick tandoor.

- Fill the inner part of the circle with blocks, cutting off the excess from the blanks with a grinder with a diamond blade or a special disk for cutting stones. Number each brick and record their location on paper.

- Free the site from the material, apply a layer of mortar to the entire surface and lay the blocks according to the sketch.

Construction of tandoor walls

In order for all the elements of the stove to correspond to the pre-designed brick tandoor pattern, we recommend using a special template in the form of a frame. Without it, it is difficult to lay material around a circle with the same radius.

The dimensions of the device depend on the height and diameter of the oven. As a rule, the height of a tandoor is equal to its diameter, and the neck is 1/3 of this size. Make one side of the template, which is installed in the center of the base, from a pole 1 m high. Attach 3 planks perpendicularly to it, in increments of 25 cm: at the bottom - 30 cm long, in the middle - 25 cm, at the top - 20 cm. When rotated, it will show deviation of the wall from a given shape at a given level.

You will also need a pattern along which you can lay the bricks. A lamella from a bed under a mattress is suitable for this purpose.

Build the wall in the following sequence:

- To make the structure stable and attractive, draw a brick tandoor arrangement.

- Apply a layer of mortar on the outside of the circle with a width equal to the smaller side of the brick. Place the blocks on it in a circle, placing them on edge, standing up. Align the inner edge without any gaps. Seal the seams with mortar. After laying out the first row, tie it with wire and hide the ends between the bricks.

- In the second row, leave a small window through which air will flow into the structure. It can be closed with an iron door. It is also possible to install a chimney pipe in the opening.

- When you reach a height of 100-120, begin to form a neck, the height of which is 25-30 cm. To do this, tilt all the bricks of the higher rows slightly inward. Often the hole is made not from the top, but from the side, but in the classic version the bookmark is made from the top.

- After achieving the required shape, leave the structure for 2 days to allow the solution to harden. If you plan to cook flatbreads in the oven, cover the inside of the brick tandoor with a mixture of fireclay clay. The layer should be thick enough - at least 10 mm. To prepare kebabs or pilaf, the inside walls can be left unfinished.

- Coat the outside of the stove with mortar and then finish it with stone to add structure aesthetically pleasing. Wait 2 days for the clay to dry.

Often, poles with hooks are attached inside the oven on which meat can be hung. In the Uzbek version, a grille is provided. In addition to meat, you can cook fish and vegetables on it. All products will be evenly fried on all sides.

Rules for operating a tandoor

When using the stove, you must adhere to some rules that will extend its service life and facilitate operation:

- Raise the temperature in the tandoor gradually. In winter, burn a small amount of wood chips first and then add the main fuel. In summer, you can skip this procedure.

- It is allowed to fill fuel to a height of no more than 2/3 of the structure. There is no need to lay more, the heat will simply evaporate through the top.

- The type of fuel doesn't matter. You can use firewood, coal, brushwood; there are no temperature restrictions.

- If grease gets on the walls, do not remove it. It will simply burn out the next time you use it.

- Remove the ash with a scoop and poker through the hole at the top. This is the only drawback of the device due to the obvious inconvenience of the operation.

Some designs provide a blower from where ash can be removed through the door, but this option complicates the device.

How to make a tandoor from brick - watch the video:

No experience is required to make such a stove. construction work, all operations are quite simple. The main condition for receiving good result is the execution technological process in a given sequence. Important also has the material used and timing between stages.

Lovers of country holidays cannot imagine their pastime at the dacha without barbecue. And really, could anything taste better? fresh meat, richly flavored with spices and thoroughly fried on charcoal? If such a thing exists in nature, then it can only be meat that is baked in a brick tandoor. For those who don’t know, a tandoor is a special Turkish oven that produces kebab with simply incredible taste. And the whole secret of such an exquisite taste is that the meat is baked extremely evenly, and solely due to the fact that the spread of heat in such a design is balanced. So, today we will find out how to build a tandoor with our own hands, get acquainted with possible options and give detailed instructions on production.

How to make a tandoor on your own

Option #1. Traditional clay tandoor

According to the ancient technology mentioned earlier, a true tandoor should be sculpted, not built. Moreover, kaolin clay (ideally of Akhangar origin), which has excellent thermal insulation qualities, should be used for this. To prevent the furnace body from cracking under the influence of high temperatures, sheep or camel wool is added to the clay. Making an authentic tandoor is extremely difficult, since Asian craftsmen are not very clear about the exact composition of kaolin clay. Simply put, you will have to perform all manipulations “by eye”, constantly conducting experiments.

An approximate manufacturing technology for the classic version of the described furnace looks approximately as follows.

Step 1. To make a tandoor with your own hands, you need to mix clay with wool (the length of the fibers of the latter should be about 1-1.5 cm). The result should be a fairly viscous mixture, reminiscent of sour cream in consistency.

Step 2. Next, you need to wait 7 days for the resulting composition to dry and achieve the required condition. During all these days, the mixture should be stirred periodically so that drying occurs evenly. All water that accumulates on top must be removed immediately (it cannot be mixed into the composition).

Note! The lower the moisture concentration in the composition, the lower the risk that the oven will crack during drying or firing. When the preparation period is over, the consistency of the mixture should resemble dense plasticine, suitable for modeling.

Step 3. From the resulting “plasticine” you need to mold long sheets of oblong shape with a thickness of at least 5 centimeters. From these plates, gradually moving in a circle, you need to build a tandoor.

Traditional dimensions look something like this:

- the neck should be 50-60 centimeters in diameter;

- before narrowing, the diameter should correspond to 100 centimeters;

- The recommended height of the structure is from 100 to 150 centimeters.

It is necessary to leave a hole in the bottom side of the case through which air will flow inside.

Step 4. When the oven is ready, it is transferred to the shade and left for another 30 days to dry.

Step 5. The walls must be lined with fireclay bricks, and adhesive composition in this case, it can be either kaolin clay itself or a special clay oven mixture that contains plasticizers and quartz sand. Sand or salt must be poured into the cavity between the resulting layers, periodically compacting while filling.

Step 6. The inner surface is coated with cotton oil.

Step 7 After this, all that remains is to fire finished oven, that is, to bring the material to the state of ceramics. The temperature should increase gradually and not very quickly. The duration of firing can reach 24 hours, this is explained by the fact that if raw clay is subjected to sudden heating, it can crack.

Video – Traditional tandoor: technology and interesting facts

Option #2. Making a tandoor with your own hands from a barrel (simplified technology)

It's no secret that making such a stove using the technology described above is extremely difficult, especially in the absence of special skills and knowledge. And many home craftsmen will confirm this. The surfaces turn out to be crooked, and the clay often cracks when drying. To avoid this kind of trouble, a simpler “recipe” for this design was developed, which is based on creating clay walls around a barrel made of wood.

To create such an Asian oven, you need to prepare in advance:

- kaolin clay;

- vegetable oil;

- fireclay sand (and its fraction should not exceed 0.5 millimeters);

- a wooden barrel with iron hoops;

- wool (one of the options listed above).

Now let’s find out how to make a tandoor from all this with your own hands. First, fill a barrel full of water and wait at least 24 hours for the wood to soak and swell. After this, mix wool (0.5 parts), sand (2 parts) and clay (1 part), wait a few days until the resulting mixture dries. The next step is to drain the water and completely dry the wood. The internal surfaces of the barrel are processed using vegetable oil, after which they are soaked overnight. Next, the inside of the barrel is covered with a 4- or 5-centimeter layer of the resulting clay mixture. The composition is leveled with wet hands so that the walls are as smooth as possible. As you move upward, the thickness of the clay layer should increase, that is, the neck of the kiln should gradually narrow. Traditionally, it is necessary to leave a small hole at the bottom through which air from outside will enter the housing.

Note! To dry, the structure should be moved to a ventilated, shaded and dry place. The process may take 3 to 4 weeks. Over time, the barrel will begin to lag behind the clay walls.

When everything is dry, the iron hoops must be removed and the barrel itself removed from the tandoor. Next, the stove is installed on a thick “cushion” of sand and fired, that is, it is melted for the first time. It is necessary to light a small flame inside and maintain it for approximately 6 hours, periodically loading small portions of fuel. After this time, the stove is covered with something, the fire is turned up higher and eventually brought to the maximum level. It is important that the tandoor cools down slowly afterwards.

If desired, you can additionally insulate the stove to improve its thermal insulation qualities. To do this, you can build brick walls around it.

Option #3. We make a tandoor from bricks on our own

So, do it classic version the oven is quite difficult, we have already found out. What’s more, not all masters succeed in this! Therefore, in order to simplify the task and not take unnecessary risks, we recommend that you familiarize yourself with the technology of making a brick tandoor - this way you are guaranteed to get the desired result, despite the fact that the finished stove will be very different from the traditional version described above.

First you need to prepare:

- stove brick;

- wooden template;

- masonry sand mixture;

- cement;

- kaolin;

- reinforcing mesh;

- sand.

The main thing is just beginning - the manufacturing procedure itself. The process consists of several stages, let's look at the details of each of them.

First stage. Base

Select a suitable flat area on which the future tandoor will be located with your own hands. Dig a round hole there, the diameter of which should be slightly larger than the planned diameter of the structure. Fill the bottom of the resulting hole with a “cushion” of sand (the thickness should be about 10 centimeters).

Cover the finished “pillow” with an iron mesh constructed from reinforcing rods or thick wire.

Fill the hole concrete mixture, carefully align everything using iron rule. Don't forget to check the levelness of the surface using horizontal level. Now wait at least 7 days for the solution to set and concrete surface regained its original strength.

Second phase. Brick walls

Start laying the brick in a circle, the diameter of which you designated at the planning stage. As a rule, this is about 100 centimeters. Place the bricks on the end and, using the frame as shown in the image below, begin to form a circle. For installation, use only a kiln solution consisting of fireclay clay, appropriate plasticizers and, of course, quartz sand. This will ensure that the composition will not crack when fired, will set quickly and will generally be plastic.

Traditionally leave the body at the bottom small hole, which during operation will serve as a blower. This can be either a small window equipped with an iron door or a chimney.

If the height of the stove is 100-120 centimeters, then four rows of bricks will be enough. Typically, when laying the last row, a tapering neck should be formed in parallel; therefore, the brick at this stage should be laid with a slight inclination towards the inside.

Third stage. We carry out coating and cladding

Coat the internal and external surfaces of the constructed furnace with refractory clay, the thickness of which should be approximately 5 centimeters. In addition, finish the body of the tandoor natural stone- So ready product will look more attractive.

Fourth stage. We fire the kiln

Let us immediately make a reservation that the firing procedure in this case is performed in the same way as in the previous two options. It is necessary to light a fire inside the tandoor, the walls of the oven must gradually heat up to a high temperature (more precisely, up to 400 degrees), and then slowly - and this is very important! - cool down.

For a more detailed look at how to build brick tandoor at home, we recommend that you familiarize yourself with the thematic video below.

Video - Making a tandoor with your own hands

Features of operation

There are a number of requirements that must be followed when using a stove such as a tandoor. Let's start with kindling. Here a lot depends on the time of year. In winter, for example, the temperature should increase gradually - first light the wood chips, let them burn, after which you can add the main fuel. In the summer, it is quite possible to do without preliminary kindling with wood chips. As for the volume of fuel, it should be 2/3 of the total volume of the stove. You can put more, but in this case a lot of thermal energy will simply evaporate without heating the walls of the case.

As for temperature restrictions, there are none at all for tandoor. Use it whenever you want, the main thing is not to forget what is said in the previous paragraph.

Cleaning the stove is also not difficult: just take a dustpan, poker and collect the ash. If fat gets on the walls, don’t worry - it will simply burn off during subsequent use.

Advantages of using the design

The problem of poorly cooked kebabs is familiar to everyone: with poor-quality heat treatment, part of the meat is fried to a black crust, while the remaining pieces turn out almost raw. Why is this happening? The reason is the uneven distribution of coals under the skewers, as well as the fact that they are coals with different temperature indicators. And the results of such roasting are described above.

But a brick tandoor is a completely different thing. Thanks to its unique design, this oven allows you to completely forget about such an unpleasant thing as undercooked meat. Another advantage of the tandoor is that not only meat is baked in it, but also traditional oriental flatbreads - tasty, and at the same time very healthy for the body.

Tandoor - design features of the stove

The design of such a furnace is very similar to most structures of this kind, but some differences still exist. Thus, the inner surface is made of an unusual (at least for such ovens) material - ceramics. But both wood and coal can serve as fuel (brushwood can also be used).

Externally, a brick tandoor is very similar to a hypertrophied clay jug, which was lined with brick. Coal or wood is placed directly inside the structure and then set on fire. Then, when the fuel turns into coal, the kebabs are placed in the oven. Typically, the meat can be hung on a hook to a special pole, which should be taken care of in advance, and placed with the sharp end on the foundation.

Note! Another advantage that a brick tandoor has is that it retains heat for quite a long time. Thanks to this, you can have time to make several batches of baked meat at once.

An interesting fact: the described stove first appeared in distant Mesopotamia, and soon gained considerable popularity among Asian peoples. It is for this reason that a number of oriental kitchens cannot be imagined without this miracle oven.

Operating principle

To find out how to make, you must first become familiar with the operating principle of this design. As an example, let's take a look at the classic Uzbek tandoor made of brick. Outwardly, such a tandoor is comparable to a clay cauldron, but only turned upside down (it’s as if the top has been swapped with the bottom). At the bottom of the furnace there is a special hole, which is also called a blower.

The base, made of clay, is covered with brick. What is important is that there remains a small amount of space between the inner and outer layers. air gap, which is subsequently filled with sand or salt (the latter option is more preferable).

The fuel is placed into the housing through a hole located on top. Although there are versions of the stove in which it is located on the side, this arrangement is practically never found in the classic Uzbek version.

Note! The main disadvantage of the tandoor is that ash is removed from the body through the upper hole, which for obvious reasons is very inconvenient (this does not apply to portable stoves).

And to make it more convenient to fry shish kebab, the oven of the Uzbek version has a special grate. You can place not only meat on such a grill, but also, for example, fish or vegetables. All these products are guaranteed to bake equally well.

Note! If the tandoor is built competently and in compliance with technology, then you can cook on it within six hours after one-time kindling.

What is the secret of such high heat-saving properties of the structure? And the secret lies in the materials from which such stoves are constructed. Such materials have simply incredible heat-accumulating properties: for example, if you try hard, the walls of the tandoor can be heated to a temperature of 400 degrees.

As for the varieties of tandoor, the classification in this case is based on the installation location of the device - according to this parameter, the described stoves can be:

- pit;

- ground;

- portable.

Today’s article will discuss several options for creating a tandoor at home, however Special attention will be devoted to making a brick oven. This is explained by the fact that, for example, a portable structure is, in fact, a type of barbecue, while a pit structure is used in most cases for heating small rooms. So let's get started.

Staying in the country is a unity with nature. I want to cook food over a fire, sit by the fire, listening to the twilight rustles. A grill or barbecue is most often used to cook food over a fire, but we suggest you make a tandoor with your own hands. What it is? This is an oriental oven-broiler, which allows you to prepare a lot of delicious dishes that are simply impossible to prepare otherwise. Samsa, lavash, oriental meat - all this can be made in the tandoor. Moreover, the meat turns out very tasty because it is suspended in a horizontal position, as a result the fat does not drip onto the coals, but flows down over the pieces of meat, making it juicy and soft.

Shish kebab in a tandoor turns out much tastier due to the vertically positioned skewers. On the grill, the meat needs to be poured with marinade or sprinkled with water, but here it turns out tender and juicy

It is very interesting, in the opinion of a European, that flatbreads and samsa are prepared in the tandoor - they are attached directly to the walls of the oven and baked in this way.

Oriental flatbreads and samsa are baked in the tandoor, stuck to the walls of the oven. This bread has a special taste. Having made your own tandoor, you can bake samsa, pita bread and delicious flatbreads

The traditional shape of such a stove is round. It can be located both above the ground and underground. Today, many summer residents build a brick tandoor; it is not that difficult to make, but oriental cuisine will bring a lot of pleasure to both family members and guests.

In the East, a tandoor can also be located in a house; it is installed in the center of the room to warm the air in the room during the cold season.

A small tandoor can be made on a platform with wheels; you can transport it to any place in the garden.

You can buy a tandoor if funds allow. This ready-made tandoor with a platform on wheels can be installed anywhere in the garden or in the house

If the stove is stationary, it is better to place it on a rocky or sandy soil, away from buildings and green spaces. The ground under the tandoor should be dry.

How to make a tandoor? For construction, you can use stone blocks, ceramic clay brick or white fire brick. First, the base is laid out. A brick tandoor is quite heavy, so the base must be strong. The base of the furnace is like a foundation, in which an opening is made where the fuel is placed.

You can build a tandoor directly on the ground, in this case, under the base you need to dig a hole in the shape of a circle, with a diameter of 120-130 cm. We fill the bottom with sand (a layer of 15-20 cm), and begin to lay out a brick well.

Base for tandoor – sand cushion is done at the bottom of the foundation, the area around it is also covered with sand. At the bottom it is convenient to place a grill for coals

You can use a ready-made stove mixture as a mortar for masonry. It consists of plasticizer, red clay and quartz sand. The masonry can be either horizontal or vertical; in the first case, the stove will retain heat longer, the second is more economical - much less bricks will be needed.

Tandoor, lined with vertical masonry with a pipe for exhaust gases. Less material is consumed for the manufacture of such a furnace.

A brick tandoor lined with horizontal masonry - the wall thickness is greater, so it retains the heat inside longer. Any tandoor should have a hole at the bottom to remove flue gases.

To clearly see the dimensions of the future furnace, you can first make an order - masonry without mortar. We work with brick using a grinder with a diamond cutting wheel for ceramics.

The ordering is done to visualize what your tandoor will look like. After this layout, you can start working with the solution. The tandoor can be built on the ground or on a brick foundation

Making round masonry is not easy, a drawing in life size, made with the help of a protractor and a compass, the ability to handle an angle grinder is also important.

The diagram clearly demonstrates the structure of a brick tandoor. The manufacturing features of the stove may differ, but the basic principle of construction is always the same - a base with a hole for fuel and a body that curves upward

A pattern of bricks is the basis for forming a circle. Do not skimp on the mortar when laying, and use a level to check the horizontal position.

For making tandoor oriental masters used a similar template. By laying out the bricks according to the template, the stove will gradually acquire a rounded shape tapering upward

The tandoor is narrowed at the top - this is done to keep the heat inside. In order to achieve this effect, the bottom layer of brick must be cut off; when laid, the shape will resemble a vault. After the masonry is ready, it should be cleaned inner space ovens from traces of solution. We use dry clay to fill the seams from the outside. The inner surface is also coated with clay, which is mixed with finely chopped grass.

When the kiln is dry, it is first heated with paper, and then the firing temperature is increased. This is the easiest way to make a tandoor, and if you want to refine it, the structure can be coated with clay. In the east, stoves are decorated mosaic tiles, sandstone, ceramics.

The video demonstrates how to make a brick tandoor using the template:

Option #2 – tandoor from a wooden barrel

Of course, a brick tandoor is the most durable and practical, but if you wish, you can use other methods, which we will now talk about. This requires skill in working with clay.

You need to find a small barrel with poorly fitting hoops. The inside of the barrel is impregnated with refined sunflower oil; for impregnation, we leave it overnight.

Then we prepare the solution - sheep's wool for reinforcement (length up to 15 cm), fireclay clay, fireclay sand. The ratio, respectively, is 0.05 – 1 – 2. We make a thick solution and fashion it according to inner surface barrels of the furnace body (thickness – 20-30 cm). The solution is smoothed and dried for a week using incandescent lamps. Then the hoops can be removed and the barrel can be disassembled. After this, the product is subjected to secondary firing.

Option #3 – roaster using a plastic barrel

You will need a plastic barrel of a classic shape. We fill it with water, after filling the barrel slightly increases in size, it outer surface coated with fireclay mortar, it is compacted and smoothed until the outline of the furnace is formed. The product is also dried for a week, and then the water must be drained. The barrel will become smaller and can be removed from the new tandoor.

You can also place a cauldron on top of the stove for cooking pilaf and other dishes, but to do this you need to adjust the crown to the volume of the cauldron, the crown is coated with clay.

Building the stove is the main point, but you will also need to make metal fastenings for the shapmur. For example, here are three staples with a metal hoop in the center. The easiest option is to use a strong rod, lay it along the crown, and attach a skewer to it

If you have pottery skills, the tandoor can also be used as a decoration on your property. For example, create a “house” like this for preparing delicious oriental dishes

We've looked at several simple ways making a tandoor at the dacha. These are the simplest answers to the question of how you can make a tandoor with your own hands. More complex options They offer the manufacture of a structure reminiscent of a Russian oven, but this is a bulky structure and it is quite troublesome and difficult to build it, but a simple tandoor is quite suitable for a dacha and the dishes in it turn out very tasty, try it and you will see for yourself.

The brick tandoor is the best option for making it yourself. Many people want to make this oven out of clay, but this design will not last long, because baking ceramics requires temperatures over 1000 degrees. In addition, the bricks are cheap enough and the process is so simple that there is no reason not to build a tandoor with your own hands.

Drawings and dimensions

There are two types of brick tandoors - horizontal and vertical. The vertical one is considered classic; its lid is on top, not on the side, and it is this one that is used for preparing Uzbek cuisine. In addition, it is easier to build since there is no need to wall the base.

The general layout of the tandoor looks like this:

Three-digit numbers indicate dimensions(in mm). It should be noted that they may vary depending on the type of masonry and the number of rows assembled. The rest are marked:

- Bassoon trims.

- Fireclay bricks laid vertically in three rows.

- Expanded clay.

- Red brick.

- Expanded clay with clay mortar.

- Bassoon trims.

- Paving slabs.

- Blower.

- Metal plate above the blower.

- Grate bars.

- Galvanization.

- Hanging for vegetables.

- Skewers.

What will you need?

To stock up on everything you need to build a tandoor, you will have to visit a hardware store.

Tools

The following tools will be used:

- Grinder with a diamond wheel designed for ceramics.

- Plaster rule and spatula.

- Paint brush.

- A vat for mixing concrete or an electric concrete mixer.

- Building level.

- Hacksaw saw.

- Hammer and nails or screwdriver and screws.

- Shovel.

- Pliers.

Materials

Titles necessary materials and them approximate quantity are displayed in the table. It should be taken into account that the actual consumption may differ both up and down.

Table. Material consumption for tandoor construction

Making a tandoor with your own hands

Since the brick tandoor has enough heavy weight and is installed under open air, its long-term service can only be ensured by the right foundation.

Before building it, you need to find out how high the The groundwater at the intended installation location of the tandoor. If they are close to the ground surface, you will have to find another area. Next, determine the type of soil. If it is clay or loam, you will need reinforced columnar foundation. On sandy and sandy loam, as well as on sod-podzolic soils, you can get by with a monolithic casting concrete slab. Since these soil types are the most common, a method for creating a concrete foundation will be described.

Pouring the foundation

The base for the tandoor has a size of 100 x 100 cm and a thickness of 10 cm. It is made like this:

Concrete mortar is prepared according to this recipe: three parts sand, one part gravel and one part cement. Add enough water to get the consistency of thick sour cream.

Making rules

While the foundation is hardening, it’s time to start making the rule. In shape it resembles a yacht sail and serves to ensure that the walls are smooth.

Since a regular tandoor has the same height and width at the base, the length of the bottom of the rule will be equal to half its height. The diameter of the neck is one third of the width of the base. Based on these measurements, a rule is made, placing its transverse strips at a distance of 25 cm.

For convenience, you can draw a pattern on any sheet of paper or cardboard.

Construction of walls

When the foundation has acquired sufficient hardness, the walls begin to be walled.

This can be done in two ways - placing the bricks vertically or horizontally. In the first case, significant savings result consumables, and in the second, the tandoor retains heat much longer and can reach a higher temperature. If it is planned to build a tandoor for household use, vertical masonry will fully justify itself, and will also take less time.

The process looks like this:

IN classic tandoor there is no exhaust pipe. Some craftsmen include it in the design of their stoves and claim that this greatly facilitates use. For example, it can be used in rainy weather, because air access to create draft occurs not through a slightly open lid (where water enters, which extinguishes the fire), but through a horizontally located pipe.

External processing

When brickwork will be finished, you need to start processing the outer part of the tandoor. It is plastered with a stove mixture, making sure that its layer is not less than 1 cm.

The upper edge is rounded and four recesses are made in it, into which the supporting parts of the lid are then placed.

After this, the tandoor is covered with cellophane and left until completely dry plaster.

Terms of use

Tandoor is a unique and multifunctional oven. You can bake flatbreads and pies in it, fry meat, bake potatoes and cook many more dishes.

Flour baked goods are “glued” to the walls of the tandoor. This is what the process of making samsa looks like:

The finished pies are pryed with a special metal spatula, placing a metal sieve with a long handle. The baked goods fall into the sieve and are taken out.

The shish kebab is prepared by hanging the skewers vertically on a special stand and closing the lid on top. In the absence of one, you can build the following structure from two empty skewers or thick metal rods:

Vegetables are baked, laid out on special grates. You can also put pizza, a large pie with filling there, or put tin bread. Assembling such a device with your own hands is not difficult. The grill is hung in the same way as skewers with shish kebab:

Cooking begins after the wood has burned out and only the coals remain, giving heat. The tandoor heats up to a temperature of about +450 °C and gradually cools down. It stays hot enough for cooking for 6-7 hours.

It is important to remember that there is a risk of getting burned, so you should work with the tandoor carefully and never let children near it.

Tandoor built near a private house or on summer cottage, easily replaces both the grill and the oven. It can be used at any time of the year, and the consumption of firewood is so economical that it cannot even be compared with other stoves. If the question is whether to build a tandoor or a barbecue, the choice is obvious.