When construction works are nearing completion, the question arises of how best to insulate the bathhouse. The choice of suitable material and methods of its installation, insulation technology are very important moments.

How to choose insulation

What is the best way to insulate a bathhouse? For this, natural or synthetic materials are used.

Natural insulation:

- cuckoo flax;

- red moss;

- flax tow;

- hemp hemp

- sphagnum.

These materials do not require serious material costs, are highly environmentally friendly and will help create a special atmosphere in the bathhouse, filling inner space natural natural aromas.

The main disadvantages of organic materials that need to be taken into account when choosing which insulation is best to insulate a bathhouse:

- fragility of the material;

- significant labor costs;

- the need to constantly update the insulation.

It is necessary to provide protection from small rodents, birds and insects.

Many homeowners believe that it is better to insulate a bathhouse with synthetic materials that do not rot and are not damaged by rodents.

Jute felt

What is the best way to insulate a bathhouse from the outside or the inside? Jute felt can be used as inter-crown insulation for a bath. This is an organic natural material made from plant fiber.

Flax-jute felt is used not only for thermal insulation, but also for excess moisture from the interior of the bathhouse

Flax-jute felt is used not only for thermal insulation, but also for excess moisture from the interior of the bathhouse To improve performance qualities, flax fiber is added to jute fibers. The result is flax wool or flax jute felt. The form of material release is tape reels. This allows you to select insulation for logs of different diameters.

Flax-jute felt is used not only for thermal insulation, but also to remove excess moisture from the interior of the bathhouse. This is a durable material that will not be damaged by any animals.

Expanded clay as insulation

Expanded clay is a bulk material of natural origin. It is a granule with a porous structure. Expanded clay is often used for insulating baths or other buildings due to the following qualities:

- moisture resistance;

- relatively small specific gravity;

- high strength granules;

- resistance of granules to mechanical damage;

- durability;

- low price.

Floor insulation with expanded clay

Floor insulation with expanded clay Working with expanded clay is easy. Other bulk materials can be used together with it.

Synthetic insulation

Currently, synthetic insulation materials are produced in large quantities and can be of the following types:

- extruded polystyrene foam (XPS boards) or regular;

- Styrofoam;

- mineral wool;

- glass wool

Insulating the floor in a bathhouse with foam plastic

Insulating the floor in a bathhouse with foam plastic Each material has unique properties:

- Expanded polystyrene provides reliable thermal insulation. At the same time, the material has low cost and low specific gravity. It should be borne in mind that ordinary polystyrene foam is fire hazardous and is easily deformed when exposed to high temperatures. Therefore, in the bathhouse it is used to insulate the dressing room, utility rooms, and rest rooms. Expanded polystyrene cannot be used in the washing and steam room.

- For a bath, it is better to choose XPS boards or extruded polystyrene foam. This material has a sealed cellular structure and a not very high specific gravity. XPS boards are resistant to moisture, compression and high loads. This gives them durability and reliability during operation.

- Polystyrene foam is used for external insulation of a bathhouse built of brick or cinder blocks. It is glued to the outside vertical surfaces buildings. Plaster and finishing material are applied on top. Polystyrene foam is highly flammable, so interior decoration It cannot be used in a bathhouse.

- The main material for the production of mineral wool is molten rocks or waste from metallurgical production. Therefore, the cost of this insulation is low compared to other similar materials.

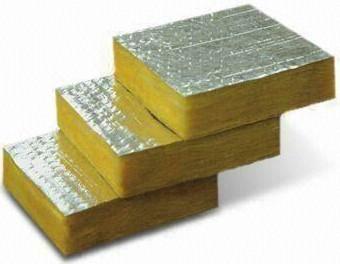

Bath insulation with mineral wool

Bath insulation with mineral wool The result is an insulation that has the following positive properties, How:

- reliability;

- non-hygroscopic;

- strength;

- Fire safety;

- durability.

Working with such insulation is easy and convenient. The service life of the material is quite high. Therefore, when deciding how to insulate a bathhouse, you can opt for sheets or mats made of mineral wool.

Insulation with mineral wool allows you to provide the following conditions in the bathhouse:

- low thermal conductivity;

- high sound insulation;

- hydrophobicity.

Glass wool is produced by interweaving fine fibers of inorganic glass

Glass wool is produced by interweaving fine fibers of inorganic glass The main thing to remember is that mineral wool is easily subject to mechanical damage. Therefore, when using it you need to act carefully and carefully.

Glass wool is produced by interweaving fine fibers of inorganic glass. High thermal insulation properties are ensured due to the large volume of air in the finished material.

The cost of glass wool is low. It is sold in roll and/or tile form. The thickness of glass wool varies, so it is always easy to choose the right option.

Preparatory work

When the insulation is selected, you need to purchase everything Additional materials necessary to work with it, prepare the tools. To insulate a bath you may need:

- construction knife;

- roulette;

- level;

- hammer;

- brushes and/or spatulas;

- sledgehammer;

- construction mixer;

- container for mixing solutions;

- work clothes, mittens, rags.

When the insulation is selected, it is necessary to purchase all additional materials necessary to work with it and prepare the tools

When the insulation is selected, it is necessary to purchase all additional materials necessary to work with it and prepare the tools It is better to make a list of everything you need after it has been determined how best to insulate the walls of the bathhouse, floor or ceiling, and all the necessary materials have been purchased.

How to insulate a bathhouse from the inside

When thinking about the best way to insulate a bathhouse from the inside, you should remember the high level of moisture content in the interior space. Therefore, vapor barrier must be provided. This will preserve the integrity and core beneficial features insulating material. The walls of the room will be less damaged by moisture and high temperatures.

What is the best way to insulate the walls of a bathhouse? Aluminum foil is considered the most convenient vapor barrier for a bath. This material protects the heat insulator from destruction and helps conserve heat in the interior of the bathhouse. After applying the foil, the seams between the sheets must be sealed with special metallized tape.

On a note! Different sections of the bathhouse have different levels of moisture and temperature. Therefore, the decision on the best way to insulate a bathhouse inside depends, first of all, on the specific room.

Various insulation materials are used, and their installation technology is also different.

Walls in the steam room

The walls in the steam room are exposed to high temperature and humidity. Therefore, how best to insulate a steam room in a bathhouse should be considered in detail.

First, the sheathing is attached to the walls. It is best done using dry slats and/or thin timber. The resulting cells should be smooth and the same size. They will be covered with fiberglass.

Insulation with aluminum foil

Insulation with aluminum foil A heat insulator is laid on top of the fiberglass. Basalt fiber is considered the most reliable for steam rooms. The last layer is a vapor barrier. Aluminum foil is used for this.

When all the work is completed, decorative finishing of the walls is carried out. To do this, you can use lining made of durable types of wood. It should be remembered that if the interior space of the bathhouse is not divided into several rooms, insulation according to the described scheme is carried out everywhere.

Basalt fiber is considered the most reliable for steam rooms.

Basalt fiber is considered the most reliable for steam rooms. How to insulate a ceiling

The better way to insulate the ceiling in a bathhouse depends on the purpose of the particular room. Hygroscopic material should not be used in the washing room and/or steam room. In the wash room or dressing room, you can use plastic film or kraft paper for vapor barrier.

On a note! To improve air circulation between the vapor barrier and finishing material it is necessary to leave a ventilation gap (gap) of no more than 2 cm.

This will speed up the drying of the casing after using the bathhouse, otherwise excessive moisture will cause the material to rot and will have to be replaced.

How to insulate a floor

Significant heat losses in the bathhouse occur not only through the ceiling and walls, but also through the floor, especially when the bathhouse is used in the cold season - winter, autumn, early spring.

To figure out how and what is the best way to insulate the floor in a bathhouse, you should remember that the order of laying the floor pie must be strictly observed. The earthen floor must be leveled, cleared of debris and foreign objects and leveled. You need to pour a concrete screed onto the prepared surface.

A layer of rolled waterproofing material must be laid on the set concrete. This can be roofing felt or plastic film.

Next, the entire surface is covered with a layer of heat insulation. You can use both sheet and linen material. Then roofing felt or polyethylene is re-laid. The final layer is concrete screed.

The laying of all layers of the floor pie must be carried out carefully. You especially need to pay attention to the tightness of each layer - this will preserve the integrity of all materials. Correctly carried out internal insulation will create comfortable conditions For correct use baths and heat preservation.

External insulation of a bath

The better way to insulate a bathhouse from the outside depends on the main building material from which the building was built.

External floor insulation in a bathhouse

External floor insulation in a bathhouse For external insulation of brick baths, mineral wool is most often used. It is best to apply this material in 2 layers, overlapping the seams between the sheets laid earlier. This will prevent the appearance of cold bridges and help retain heat.

A bathhouse made of blocks is insulated according to a similar scheme. For expanded clay concrete blocks, the layer of external insulation may be slightly thinner.

Wood retains heat well. In this case, the question of what is the best way to insulate the walls of a bathhouse from the outside is a little easier to solve. The basic scheme for applying a layer of thermal insulation depends on the wood building materials used.

Important! If the bathhouse is built from timber, it is necessary to seal the seams of the main frame. To do this, you need to make neat layers of flax-jute fiber.

Solving the question of how best to insulate a frame bath requires special attention. Free space between the frame components must be filled with a heat insulator. For this purpose, mineral wool is used, protected on both sides with a waterproofing film.

If a log frame was erected for a bathhouse, only the roof joints need to be insulated. For this, it is optimal to use flax-jute felt or other natural material.

Internal insulation of a bathhouse is one of the most important stages arrangement of this building. Without high-quality thermal insulation, the owner will have to spend much more resources on heating the steam room, and the atmosphere in the bathhouse itself without properly installed protection will leave much to be desired.

Since ancient times in Rus', moss, felt and even flax have been used to insulate baths, mainly due to the lack of other insulation materials - plant fiber either rots or dries, so today it is not used for basic thermal insulation.

Red moss - insulation

The main difference between insulating a bathhouse and a similar event in an ordinary home is simple: in the steam room you need to maintain the heat for as long as possible, i.e. the high temperature should remain indoors for as long as possible.

Thermal insulation work in a bathhouse can be carried out using a wide variety of materials. Eg, ideal solution is modern insulation based stone wool with an applied foil coating - it does not burn, can withstand temperatures up to 750 degrees, effectively retains heat, does not rot, and is not of interest to rodents.

After reading the information below, you will receive a complete theoretical understanding of the process of performing internal insulation of a steam room, and also study step-by-step instructions for self-installation of thermal insulation materials.

Any construction, repair and finishing activities begin with the preparation of materials, without which the implementation of the planned work will simply be impossible. Pay due attention to studying the list below: it is better to spend a little time reading and immediately buy everything you need, than to later return to the store and buy more of what you forgot.

Insulation

The main component of the list under consideration. The modern market offers a wide range of thermal insulation materials, but not all of them are suitable for use in a steam room - humidity and temperature may be too much for you. To insulate a bathhouse, the following are most often used: expanded clay (floor insulation), materials based on stone wool, and expanded polystyrene.

Important! It is strongly not recommended to use polystyrene foam to insulate the steam room itself - at high temperatures, material of dubious quality can most likely emit substances harmful to human health.

Comparative characteristics of the mentioned materials are given in the following table.

Table. Comparison of popular bath insulation

| Evaluation criterion | |||

|---|---|---|---|

| Structure | Bulk material of natural origin. Presented in the form of granules with a cellular structure. | Fibrous structure. The arrangement of fibers is both vertical and horizontal, disordered. | Open cellular structure. |

| Moisture permeability | The material does not allow water to pass through. | Mineral wool insulation has virtually no tendency to absorb moisture. | Moisture permeability is extremely low. |

| Weight | Easy | Medium-light | Easy |

| Strength | High | Average | Average |

| Compression resistance | High | From low to medium, depending on the specific type of material and manufacturer technology. | Average |

| Toxicity | The material is safe | No toxic properties | Over time, it begins to release harmful substances |

| Possibility of use under high load conditions | Suitable | Depending on the brand of material | Not suitable |

| Tendency to decay | The material retains its original integrity for a long time | Durable insulation | Has a tendency to decay |

| UV resistance | Does not react in any way to exposure to sunlight | Characterized by high resistance to ultraviolet radiation | Prolonged direct contact with sunlight has an extremely negative effect on operational characteristics material |

As noted, expanded clay is suitable for insulating bath floors. Bulk material allows you to provide the required thermal insulation of both wooden and concrete structures. Mineral wool insulation is optimal for insulating both walls and ceilings. The best option, as noted, is thermal insulation material based on stone wool, equipped with an additional foil coating - the key characteristics of such insulation at a higher level.

Prices for mineral wool

mineral wool

In accordance with the current provisions of the technology for carrying out the work in question, the joints of the insulation boards must be glued with foil tape. This will create a sealed surface with the highest possible thermal insulation properties.

Prices for foil tape

foil tape

The elements of the thermal insulation coating are placed in the cells of a pre-assembled sheathing, for the assembly of which wooden blocks are used. Select the section of the beams in accordance with the thickness of the thermal insulation. For example, if you are installing a 10-centimeter thermal insulation layer, use bars with a similar thickness or width to assemble the frame.

Choose the distance between the bars 1-2 cm less than the width of the slabs or roll of insulation. For bulk materials the optimal distance between the bars is 45-60 cm.

The sheathing elements (bars) are fixed using dowels/screws (if the surface is wooden) or anchors (if the base is stone). The length of the fasteners is also selected in accordance with the base material: for wood - 2-2.5 cm, for permanent structures - from 4 cm.

The specific length of fasteners is determined in accordance with the characteristics of their use. For example, during the installation of sheathing, the fasteners must be of such length that they ensure high-quality fixation of the beam/profile of the selected section. The cross-section of the beam itself, as well as the profile parameters, are determined in accordance with the thickness of the thermal insulation layer being installed.

Additional materials

If you insulate a bath using a material other than foiled mineral wool, you will additionally have to purchase a water vapor barrier film.

If filling is planned concrete screed, the job set will increase to include the following positions:

- reinforcing mesh;

- mixture for pouring the screed or materials for preparing it yourself (cement, sand, water);

- lighthouses;

- damper tape;

- polyethylene.

Prices for water vapor barrier film

water vapor barrier film

The floors in the bathhouse can be wooden or concrete. The technology for arranging the direct thermal insulation layer does not have any special differences depending on the flooring material, except that in the case of a concrete structure it will be necessary to pour more expanded clay.

The thickness of the backfill is usually determined in accordance with the thickness of the walls. On average, a layer of expanded clay is poured at least 2 times thicker than the walls. If the height of the room allows, the thickness of the backfill can be further increased - this will help improve the efficiency of insulation.

First, for greater convenience of work and subsequently more accurate control of the evenness of the backfill, mark the base. To do this, it is enough to divide it with parallel lines into sections up to 1 m wide or along the length of the rule you use.

Important! If you are insulating a floor on the ground, at the very beginning, even before marking, you need to do the following:

- thoroughly compact the soil inside the base (if the foundation design assumes the presence of “free” soil, for example, in the case of strip supports);

- cover the walls with impregnation for waterproofing;

- cover the soil with a 10-centimeter layer of sand, spill it with water and compact it thoroughly;

- cover the sand with roofing felt with a 15-centimeter overlap on the walls. Also lay individual sheets of roofing felt with a 15-centimeter overlap. For fastening, use waterproof construction tape.

The exact procedure for insulating the floor with expanded clay, with illustrations and necessary explanations, is given in the following table.

Table. Insulation of a bath floor with expanded clay

| Stage | Illustration | Necessary clarifications |

|---|---|---|

| The film must be stretched so that its edges along the wall are higher than the floor level. If the base is already covered with roofing felt, there is no need to lay the film. |

|

| For example, a profile for drywall is suitable. The guides are set in accordance with the previously applied markings and secured in a suitable way, for example, with screws or nails. | |

| Align the beacons by level. In the future, these auxiliary devices will help you fill the most even layer of expanded clay, which will ensure best quality carrying out further planned work. Determine the installation height of the guides in accordance with required thickness thermal insulation layer. Many developers do without guides, but this is a less convenient and accurate option. |

|

| Pour expanded clay |

| The previously installed guides will help you do this as efficiently as possible. |

| For leveling, we use a rule or an ordinary strip of suitable length. | |

| To make leveling the insulation more convenient, we can use various auxiliary devices. For example, a rake will come in handy in large areas. |

The floor is insulated and ready for further arrangement in accordance with the developer's plans. At the discretion of the owner, additional thermal insulation material, for example, mineral wool or expanded polystyrene, can be laid on top of the expanded clay.

As an example, a diagram of a concrete floor equipped with expanded clay for thermal insulation is given.

Video - Floor insulation with expanded clay

Insulation of bath walls and ceilings

Wall insulation schemes will vary slightly depending on the material of manufacture. Information on this matter is presented in the following table.

Table. Wall insulation schemes

| Material of manufacture | Scheme |

|---|---|

|

|

1 – wall, 2 – thermal insulation, 3 – sheathing, 4 – sheathing, 5- ventilation gap. |

|

|

Sequence thermal insulation works remains the same for walls made of any materials: if necessary, a water vapor barrier film is attached, sheathing bars are mounted, insulation is placed in the resulting cells, another layer of water vapor barrier is fixed on top (if necessary), sheathing slats are nailed for finishing cladding (at the same time they will provide the required ventilation gap), the selected finishing material (usually lining) is installed.

The ceiling is insulated in a similar sequence. An example of a ceiling insulation scheme is shown in the following image.

Information regarding step-by-step insulation of the walls and ceiling of the bathhouse is given in the following table.

Important! Insulation will be carried out with mineral wool material with a foil layer, which eliminates the need for preliminary fastening of a water vapor barrier material to the surface. The operating procedure is considered using the example of wooden surfaces. In a relationship concrete walls and floors, the recommendations are the same, the only thing is that you need to use other fasteners and for greater convenience, the wooden guides can be replaced with a metal profile.

Table. The procedure for insulating walls and ceilings in a bathhouse from the inside

| Work stage | Illustration | Necessary clarifications |

|---|---|---|

| Information regarding the elements used to construct the frame, as well as fasteners for fixing the guides in different cases was given earlier. The mounting step of the guides is selected in accordance with the width of the insulation. Typically this is about 60 cm, but can be reduced to 59-59.5 cm so that the thermal insulation elements fit as tightly as possible. |

|

| Rules for laying slabs |

| Be sure to put on gloves first - contact of “bare” skin with mineral wool does not give the most pleasant sensation. We place the foil material inside the room with foil - thanks to this, the heat will not only be retained, but will also be additionally reflected into the steam room. |

| The slabs are installed vertically into the frame and do not require additional mechanical fastening. | |

| Installation of slabs on the wall |

Installation of slabs on the wall | The sequence and recommendations for insulating walls and ceilings are similar. To insulate the partition separating the steam room from the adjacent room, a layer 50 mm thick is usually sufficient. |

| Thermal insulation external wall requires a thicker layer - 100-150 mm (in regions with a particularly cold climate - up to 200 mm). | |

| To save money, the insulation can be made in two layers, with one layer made of ordinary mineral wool, and the second, which will “look” into the room, made of foil-coated material. | |

| The use of such insulation, as noted, eliminates the need to use additional water vapor barrier materials. |

|

| Filling the frame thermal insulation boards, seal the seams and joints with foil tape. | |

| A 1-2 cm gap is enough. The exterior trim will be attached to the same sheathing in the future. Important! The order of further installation of the lining depends on the location of the slats: if the slats are fixed vertically, the lining must be fixed horizontally, and vice versa. |

|

| The best material for the interior lining of a bathhouse is lining. The choice of cladding material is at the discretion of the owner. Fixing the sheathing elements is traditionally done using screws/self-tapping screws. |

Video - Insulation of walls and ceilings from the inside

Now you know everything about how to properly insulate a bathhouse with your own hands using the most optimal thermal insulation materials. The information obtained will help you cope with the planned events yourself, eliminating the need to contact third-party specialists and saving significant money.

Good luck!

Video - Insulation of a bathhouse from the inside, diagram

Oh, bathhouse, how nice it is sometimes to sit in a steam room and relax, but you won’t be able to do this if it’s difficult to maintain desired temperature. This happens in most cases due to poor thermal insulation or violation of technology during its installation. How to insulate the walls of a bathhouse from the inside, so that nothing can overshadow the joy of visiting the steam room? I am going to answer this question in this article. Read, don't get distracted.

Advantages of internal insulation

Yes, yes, we will talk specifically about internal insulation, since this method has significant advantages over insulating a bathhouse from the outside. At least three such advantages come to mind.

The first is the opportunity to reduce heat loss in a bathhouse that has already been built, but during the construction of which mistakes were made when insulating the foundation. This defect cannot be corrected by insulating the building from the outside, since the heat will escape through the floor, and it can only be insulated from the inside.

The second advantage is purely economic. Insulating a bathhouse from the inside requires much less materials than completely covering the entire building with thermal insulation and cladding - the work area is much smaller. In addition, when insulating a bathhouse from the inside, the main work is often carried out only in the steam room, which is even smaller in size.

Of course, other rooms, such as the locker room and shower room, also need to be insulated, but the amount of material consumed for them is several times less than for a steam room, therefore, the money spent on all this is an order of magnitude less.

The third benefit only comes into play if the winters in your area are particularly harsh. In this case, the bathhouse needs to be insulated both outside and inside, especially if the building is built of brick or aerated concrete. Even baths from timber frame, which are known for their thermal insulation properties without special treatment, in such winter conditions they cannot do without additional internal thermal insulation.

Selection of material for insulation

On this moment The construction market offers a huge number of different insulation materials for walls. But not all of them are suitable for a bath. You need to choose thermal insulation based on two facts:

- Conditions in which thermal insulation will fall;

- Characteristics of the thermal insulation material itself.

The first fact is the operating conditions. In the bath they are more than aggressive, high humidity and temperature. Its large differences, especially in winter time. From the street side the insulation will be “pressed” by frost, and on the other side by heat. This combination will inevitably lead to condensation.

In addition, high temperatures turn many popular insulation materials into hazardous to human health. Also, do not forget that the bathhouse is a building increased risk fire, so there is no need to insulate it with materials that burn well.

As for the characteristics of the material, they must correspond, again, to the operating conditions. To make it clearer, I will give an example of thermal insulation that should not be used when insulating a bathhouse. This material is ecowool. Yes, it is an excellent heat insulator, but its tendency to accumulate moisture ruins everything. When ecowool is wet, it loses its properties.

What materials cannot be used to insulate a bath?

In addition to ecowool, it should be taboo for you to insulate the walls of a bathhouse from the inside using polystyrene foam, other materials based on it, such as penoplex, and also forget about using classic mineral wool as insulation. I explain why they are not suitable.

At high temperatures, polystyrene foam and all its derivatives begin to release harmful substances that can lead to suffocation; in a steam room you may not even notice this. In addition, polystyrene foam burns well, which is not good.

Formaldehyde resins are used as a binder in classic mineral wool; their vapors are harmful to humans. Yes, all manufacturers claim that these fumes do not exceed the norm. But who cares if this is the norm for poison. And besides, this norm stands out under normal conditions, but the bathhouse is no different.

What materials are suitable for insulation?

- Peat blocks;

- Sawdust;

- Foam glass;

- Minvata on acrylic base.

Peat blocks. This is ordinary peat mixed with a natural filler such as sawdust or straw. A “porridge” is made from these materials by diluting it in water, using molds and a press to produce blocks. They do not rot, do not burn, absorb perfectly, and also release moisture back. They have good heat and sound insulation.

Sawdust is a common production waste when cutting wood. Despite its small size, it is still wood, and it has good thermal insulation. The wall in the bathhouse is insulated with slips, pouring them into niches that are previously covered with a vapor barrier and waterproofing.

Fiberboard - wood fiber boards, are nothing more than pressed wood chips. They have rather mediocre thermal insulation, but at the same time they are inexpensive.

Foam glass. As the name implies, foam glass is foamed glass with excellent thermal insulation characteristics. Doesn't highlight harmful substances, does not burn, indifferent to moisture. In my opinion, foam glass - the best option for insulating a bath, but there is a drawback, like any other a good product, the price for it “bites”. But if the issue of saving is not an issue for you, then choose foam glass, you will not regret it.

Acrylic based mineral wool. These are the same mineral wool slabs, with almost the same characteristics, but do not emit harmful substances. This is because the binder is not formaldehyde, but acrylic resin, which is absolutely inert to any chemical compounds and temperature changes.

“Pie” insulation technology

This technology has this name because of the several layers that make up the wall after the insulation work is completed. The first layer is considered bearing wall, the second is insulation, the third is a vapor barrier, and the fourth is wall cladding, which in a bathhouse is usually wooden lining. To make it clear how to use this technology, I will give an example of how a bathhouse can be insulated with mineral wool on acrylic resin.

The technology involves starting insulation from the ceiling and ending with the floor. The “Pie” begins with the installation of wooden blocks on the surface. They will serve as the basis for mounting mineral wool slabs, which, by the way, will be fastened by surprise, without the use of any additional fasteners.

In order for the insulation boards to fit securely into place, the distance between wooden blocks frame should be 1 cm less than the width of the insulation, only in this case you can be sure that the insulation will not fall out. Once the frame is ready, you can begin to fill it with thermal insulation. Make sure that during installation, the edges of the mats are not pressed, as this may negatively affect its properties.

Important: When installing insulation, all its components must fit tightly to each other. This is also necessary because if there is a gap between the plates, then moisture will accumulate in this place, and a so-called cold bridge will form, through which heat will escape.

After installing the insulation, it must be covered with a vapor barrier. Its role can be traditional roofing felt or more modern foil vapor barriers. The side that is covered with foil should “face the inside of the room to reflect heat back. All seams and joints of the vapor barrier must be sealed using aluminum tape.

Next, after all the seams of the vapor barrier have become airtight, you can begin to make lathing, on top of the vapor barrier, on the protruding frame bars. When installing, keep in mind that the distance between the vapor barrier and the future cladding must be at least 5 cm. This is necessary so that the condensate drains freely, otherwise it will fall on the lining, which will quickly rot because of this.

Features of steam room insulation

The main feature of steam room insulation is the concentration of insulation in this room compared to others. Since the steam room is the main room of the bath, it is necessary to create conditions here so that as much heat as possible remains in the room, and at the same time ensure good ventilation.

To properly insulate a steam room, as already mentioned, you need to use high-quality thermal insulation and follow the technology for its installation at all stages, from preparing the surface and installing the frame, to last stage, wall cladding wooden clapboard. Once again I would like to emphasize the importance of good sealing of the seams of the vapor barrier and dense laying of the insulation.

Sometimes it is permissible to use several layers of insulation, but even in this case, do not forget that you need to leave an air space between the vapor barrier and the finishing wall cladding.

Insulation of ceiling floor and roof

Thermal insulation of all surfaces in the bathhouse, technologically, has a few differences. They consist of only a few nuances, and the basic rules apply to both walls and floors with a roof.

For example, as already mentioned, the insulation of a bathhouse starts from the top, that is, from the roof and ends with the floor, there are several reasons for this. Firstly, it’s more convenient, you see, it’s easier to go down systematically than to rush from wall to roof, and then to the floor.

Secondly, all surfaces must have uniform thermal insulation. That is, the heat-insulating materials must fit tightly to the same elements, but on a different surface, and the vapor barrier must also overlap onto the next surface.

For example, the thermal insulation of the roof and ceiling should be adjacent to each other, the vapor barrier on the ceiling overlaps the walls in order to subsequently connect it with the vapor barrier on the wall using aluminum tape.

In turn, the thermal insulation and vapor barrier of the walls are connected to the floor in the same way. By following this technology, it is possible to achieve uniform thermal insulation and complete sealing of the room so that steam does not leave the room. The latter is especially true for the steam room.

Video “We cover the bathhouse from the inside”

A video explaining the stages of work using the example of a bathhouse with an already assembled frame and surfaces almost ready for installation of insulation.

Traditions, the healing effect of the bath, utilitarian necessity or the way of organizing leisure time - these are some arguments in favor of own bathhouse. Owners of private houses and country cottages when arranging a bathhouse, they are faced with such issues during construction and operation as the need to ensure slow cooling bath rooms. The solution is to thermally insulate the walls, floor, and ceiling of the bathhouse. Let's look at how to do this correctly.

Is it necessary to insulate the bathhouse?

Yes, you need thermal insulation:

- helps to increase the inertia of the bath, as a result it takes longer to warm up, but cools down much longer;

- minimizes heat consumption;

- reduces heating costs;

- ensures the achievement of an optimal microclimate;

- increases moisture control;

- protects against biological activity (fungus, mold).

To get all the benefits listed above, you need to take care proper insulation baths, saunas, steam rooms. At the same time, there are no obstacles to independent thermal insulation: the scope of work is small, the technology is not complicated, the material and tools are available. Recommendations and step-by-step instructions will help organize the process “from A to Z,” even for beginners without experience in construction.

How to insulate a bathhouse with your own hands

A detailed analysis of how and with what you can insulate a bathhouse, which side is better (inside or outside), where to start and how to finish.

1. From the position of the location of the insulation

- External insulation of a bath. When insulating a house, basement or garage, it has been proven that placing insulating material outside will be more effective. This allows you to protect the material from which the bathhouse is built. The roof of the bathhouse must be insulated ( attic space), in case it is a separate building.

- Insulation of a bathhouse from the inside. The operating mode of the bathhouse is such that external insulation alone, with all its advantages, cannot be done. Moreover, in different rooms of the bathhouse it is necessary to maintain its own microclimate, humidity level and set temperature. Therefore, they begin to insulate the bathhouse from the inside. Moreover, for each room they choose suitable materials, which in turn influence the choice of technology for their installation.

As you can see, the insulation process is complex.

2. From the perspective of the heat-insulating material used

Present on the domestic construction market different types insulation materials. Do not forget that a bathhouse can provide a healing effect only if natural and safe thermal insulation materials are used indoors.

Insulation requirements:

- environmental cleanliness. When exposed to high temperatures and moisture, insulating materials can release toxic substances. Considering the temperature and humidity conditions of the bathhouse, this indicator must be treated carefully;

- hygroscopicity;

- thermal conductivity. The lower this indicator, the less amount of heat the material transmits through itself per unit of time;

- biological inertia;

- Fire safety;

- ability to maintain shape;

- availability, cost and ease of installation.

How to insulate a bathhouse from the inside and outside

Let's consider which insulation for saunas and steam rooms is better and meets the requirements.

Organic thermal insulation materials

Known for a long time, even our ancestors sought to protect a heated bathhouse from heat loss using improvised means. The raw materials for the production of organic insulation are natural natural materials. Among the common ones are:

- flax tow, regular and tarred;

- sawdust;

- felt or jute;

- reed

The undeniable advantage of the listed materials is their naturalness. Disadvantages include fire hazard, ability to absorb moisture, difficulty of use, attractiveness to rodents and microorganisms.

Semi-organic thermal insulation materials

Natural raw materials are used for production, but during the production process adhesive compositions, which excludes the insulation of the steam room with their use. These include:

- reed slabs (mats);

- particle boards;

- peat slabs.

Synthetic thermal insulation materials

They are manufactured under production conditions and are combined into two subtypes:

- polymer. These include polystyrene foam, polystyrene foam, penoizol, polyurethane foam. Insulation of the bathhouse with polystyrene foam or its derivatives and near the firebox, because Styrofoam supports combustion; when heated strongly, it will release harmful styrene. But for other rooms or external insulation this material is indispensable.

An exception is the foil insulation penoizol, which is used in the steam room, due to the presence of a layer of aluminum foil that prevents the loss of infrared thermal radiation. The use of penoizol is allowed by standards;

- mineral wool. This category includes glass wool and basalt wool. The advantage is resistance to fire and high temperatures. The disadvantage is the ability to absorb moisture, which requires the use of films. Basalt wool is an environmentally friendly material recommended for use in steam rooms.

3. From the point of view of the material from which the bathhouse is built

When choosing insulation and insulation method, you need to take into account the material that was used to build the bathhouse and the climatic conditions in the region. These conditions will determine the thickness of the insulation.

Insulation of a wooden bathhouse made of timber and logs

A newly built bathhouse (made of logs or timber) does not need insulation. Wood retains heat well, plus inter-crown insulation performs a thermal insulation function. Over time, the log house shrinks and after two or three years, cracks appear between the crowns, through which heat escapes.

When insulating a log house, waterproofing and the choice of heat insulator play an important role. It is recommended to perform inter-crown caulking with natural materials or use basalt wool, because... Thanks to its structure, it helps maintain the microclimate and allows the tree to “breathe.”

In addition to glued or profiled timber, rounded logs are used to build a bathhouse. Thanks to machining, such a log has less shrinkage, so the requirements for insulation, in particular for the arrangement of the frame, are lower. In general, the insulation of a log house is carried out similarly to the thermal insulation of a bathhouse made of timber.

Insulation of a frame bath

Frame or skeleton provides great opportunities for placing thermal insulation material. Frame construction considered the most energy efficient.

For insulation frame bath It is better to use high-density soft insulation, protected by membranes from moisture (placed inside the walls). Organic insulation can also be used, in particular a mixture of sawdust, wood chips, gypsum and lime. This composition serves as a full-fledged insulation (it is placed between the layers of sheathing).

Insulation of a brick bath

Despite the high thermal conductivity of brick, baths made from it are common. A serious drawback of brick is its ability to freeze quickly, and this leads to significant heating costs. Therefore, brick baths usually have an internal wooden frame, which performs a decorative function, and thermal insulation material is perfectly placed behind it.

Insulation of a bathhouse made of foam blocks and gas blocks

Foam concrete or aerated concrete - materials used in modern construction baths Advantage cellular concrete in a porous structure that holds heat well. But this material has an unattractive appearance, plus it is able to absorb moisture (especially aerated concrete, with its open pores). Because wet wall material does not retain heat, then foam blocks need insulation, which is done from the outside.

The peculiarity of insulating foam block baths (as well as from aerated concrete and expanded clay concrete blocks) is that the material requires good ventilation. Therefore, ventilation must be done in an insulated bathhouse.

4. From the perspective of the front of work performed

As shown short review materials, each of them must be used taking into account the location and material of construction of the bathhouse. Therefore, we will consider how to insulate walls in a bathhouse from the inside in the context of individual directions.

Insulation of bath walls from the inside

The direction of thermal insulation of walls depends on what function the room performs.

The steam room is the most important part of the sauna. The temperature in the steam room can reach 90 °C (Russian bath) and 130 °C (sauna). Maintaining such a temperature is difficult and costly if you do not properly insulate the steam room in the bathhouse. The steam room can only be used natural materials. Basalt wool, laid in a frame or natural insulation, has proven itself to be excellent for those who are not ready to sacrifice the natural beauty of wood.

Insulation of walls in a foam concrete bathhouse with cotton wool

Insulation technology:

- frame device. Guides made of timber or metal profile are mounted on the wall. Since the bathhouse is a low building, it is often enough to make only vertical guides and choose cotton wool with a density of more than 65 kr./m3. The distance between the frame slats (pitch) is 15-20 less than the width of the wool and is 580-590 mm.

Important! The specificity of laying wool in a steam room is that you cannot use metal guides, but only wood; in addition, you have to take into account temperature fluctuations and the ability of wood to expand/contract under their influence.

To level out temperature fluctuations, when constructing the frame, vertical cuts are made in the timber, through which the timber is attached to the wall with hardware. The presence of grooves allows the guide to move along the wall; they also compensate for possible shrinkage of the walls if the bathhouse is built from timber.

- A membrane or waterproofing film is placed inside the frame. As a waterproofing material in the steam room, it is recommended to use penoizol, laid with a reflective layer inside the room. The junction of the penoizol strips is glued with foil tape;

- cotton wool is placed on the reflective layer or membrane;

- the cotton wool is covered with a membrane or vapor barrier film;

- a lathing is installed (a 25-30 mm thick lath is stuffed), allowing air to pass between the film and the finishing material;

- insulation

Insulation of bathhouse walls with sawdust (heat-insulating mixture)

Insulation technology:

- a wooden frame is being installed. If the lining is planned to be mounted vertically, then the frame guides should be positioned horizontally;

- preparing a mixture for wall insulation:

Sawdust - 10 parts;

- cement - 0.5 parts;

- water - 2 parts;

- lime - 1 part (used as an antiseptic);

- the prepared mixture is placed in the cells of the frame and leveled;

- finishing work is being carried out.

Insulation of a bathhouse made of timber/logs with jute

Jute - jute rope, tape, felt, interventional insulation (organic material)

Thermal insulation is carried out using a special tool - wooden hammer, mallet (weight 300-400 g), chisels and caulking spatula.

Sealing cracks between logs and beams: jute is placed (hammered) into the inter-crown cracks, while trying to lay the material as tightly as possible.

Insulation of a washing room in a bathhouse

The washing compartment, dressing room or rest room have a lower temperature, so foam plastic can be used to insulate the walls in these rooms.

Operating procedure:

- the frame is made. Some craftsmen recommend laying foam sheets with glue. But this method is only suitable for brick or foam concrete baths, but not for wooden ones;

- foam is placed between the cells of the frame. There is no need to protect the foam from moisture, so films are not used;

- finishing is being carried out.

Recommendation. Insulation of the wall near the firebox is carried out only with basalt wool with the installation of metal trim (protective screen) around the stove. This is due to the fact that cotton wool has a high melting point and does not support combustion.

Bathhouse roof insulation

An important area of thermal insulation work, because Quite a lot of heat escapes through the roof. If the roof is well insulated, insulation of the ceiling can be eliminated. However, it is possible to insulate the roof only if the bathhouse is a separate building with a pitched roof. For insulation, you can use any heat-insulating material that is laid on the attic floor.

The procedure for using synthetic insulation, wool or polystyrene foam is no different from laying it on the wall.

Execution scheme:

- arrangement of the frame;

- sawdust preparation. If sawdust is poured in the form of a dry mixture, then it must be dried, deresined, and impregnated with an antiseptic. Dry sawdust can be poured in the form of a mixture between the cells of the frame and covered with a membrane or covered with ash. But more often they are placed in plastic bags and stacked in bags;

Note. IN pure form sawdust is used only in wooden houses.

- preparation of the mixture. Insulation with sawdust - effective option thermal insulation, if the ceiling is concrete slab. Composition of the mixture for insulation (proportions of components):

Sawdust - 8 parts;

- lime - 1 part;

- gypsum - 1 part.

First, mix the dry materials and then add water to the desired consistency.

There is a second recipe:

Sawdust - 5 parts;

- clay - 5 parts.

In this case, the clay is soaked in water, diluted to the consistency of sour cream and mixed with sawdust.

Advice. Instead of sawdust, you can use straw (densely packed).

An effective insulation will be a 100 mm layer of sawdust mixture.

Insulation of the ceiling in the bathhouse

Note that it is logical to start insulating a bathhouse from the ceiling. After all warm air It collects under the ceiling, which means it is a source of heat loss. The insulation technology depends on the material used.

How to insulate the ceiling in a bathhouse

To insulate the ceiling in the steam room, basalt wool is used, which is laid using the same technology as on the wall - with the arrangement of the frame.

Insulation of the bathhouse ceiling with sawdust is carried out according to the principle of thermal insulation cold roof (attic floor). Sawdust is placed in a plastic bag and placed in a frame made on the ceiling or between the floor beams.

Recommendation. When insulating the ceiling, you need to remember that the temperature at the exit of the heating pipe is very high. In this place, only basalt wool can be used, as a material that has a very high melting point and does not support combustion. The passage of the pipe through the ceiling is covered with a stainless steel metal plate (reflective, protective screen for the furnace pipe).

Instead of sawdust, expanded clay can be used on the ceiling, poured into the frame. But it has significant weight and hygroscopicity. Therefore, according to reviews, users abandoned this material in favor of others.

Bathroom floor insulation

The floor in the bathhouse can be concrete or wood. Depending on the type used different technologies thermal insulation. Insulation of a concrete floor can be done with expanded clay or polystyrene foam.

Insulating the floor in a bathhouse with expanded clay

Execution order:

- the foundation is being prepared. To do this, the subfloor is removed and the soil is removed. The depth of the recess is 400-500 mm. below the threshold level;

- Waterproofing is laid on the floor - film or roofing felt. It is important that the edges of the film extend onto the wall to the full height of the floor after insulation;

- a rough screed with a thickness of 100 mm is performed. or a crushed stone-sand cushion of 150 mm is laid;

- Expanded clay gravel is poured. The minimum thickness of the expanded clay layer is 300 mm, otherwise it will not serve as a heat insulator;

- a reinforced mesh is laid on top of the expanded clay and a layer is poured cement screed 50-70 mm. When pouring concrete mortar it is important to ensure correct angle tilting the floor towards the drain;

- a finishing floor is formed.

It is worth noting that expanded clay can be laid without using a screed. For this purpose, a frame is made from wooden beam. Expanded clay is poured into the cells of the frame, a waterproofing film is laid on it and the finishing layer is covered. flooring from wooden board for the floor. However, this method is not suitable for steam rooms and washing rooms, where high level humidity.

When considering how to insulate the floor in a bathhouse, it is better to give preference concrete base followed by laying tiles on it (if it is a washing room or dressing room), or wooden flooring, which is best used in a steam room:

- For laying tiles, use tile adhesive and a notched trowel;

- for laying wooden flooring, the floor is ironed and then installed wooden joists, with a slope of 5° towards the drain. Floor boards are installed on the joists, maintaining a gap of 5-10 mm between the boards. The gap is needed for water drainage and ventilation.

Concrete floor in the bathhouse - practical solution, since it is resistant to moisture, and its service life is 3-4 times longer than the service life of a wooden floor on joists.

Insulating the floor in a bathhouse with penoplex

A more modern and technologically advanced method of insulation. However, many users believe that insulating a steam room using synthetic material(essentially, penoplex is extruded polystyrene foam) is incorrect, because... under the influence of high temperature it . Therefore, penoplex is used in other rooms, with lower temperatures.

How to insulate the floor in a bathhouse with penoplex

- prepare the base: remove the old screed, remove wood flooring or remove the soil if the bathhouse is new;

- pour a 50-100 mm layer of rough screed to level the floor surface for laying foam boards;

- lay sheets of foam plastic or materials from this group of insulation;

- lay the reinforcing mesh;

- pour a layer of screed 50-100 mm thick;

- lay the finished floor.

Insulation of the bathhouse floor with a warm floor system

Another option that is gradually gaining popularity is heated floors in the bathhouse. Its essence is that pipes are mounted in the screed, creating warm contour, along which heated water moves (water floor). Thus, we're talking about not about insulation, but about how to heat the floor in a bathhouse. And these are different concepts.

Insulation of openings in the bathhouse

Insulating doors and windows in a bathhouse also helps improve the energy efficiency of the room. To reduce heat loss, window and door openings are initially made minimally acceptable (in particular, the door to the steam room), and the windows are also located closer to the floor surface. But they still need to be insulated; for this it is necessary to install sealed double-glazed windows and seals along the contours of windows and doors.

Conclusion

When insulating a bathhouse with your own hands, you should not forget about the arrangement high-quality ventilation. This will have a positive effect not only on the health of bathhouse users, but also on the properties of finishing materials.

The Russian bathhouse is still made of wood, but for changing log house came technologically more advanced designs:

- log house made of rounded logs;

- log house made of timber (glued or profiled).

If the thickness of the logs of a Russian bathhouse in the old days allowed for insulation only of the space between the crowns, then the less powerful body of a rounded log, and even more so, a beam requires complex work to insulate the structure, intended for use in any season of the year.

Bath must comply with the thermos principle- keep warm at any external temperature. In this regard, the design solutions of the project are significant: according to the method of connecting wooden elements when knitting crowns, according to the location of the steam room relative to the soap room and dressing room, the height and thickness of the windows, the size doorways, the height of the thresholds, the design of the heater.

But the system of measures for insulation of external walls, floors and ceilings cannot be belittled, technological features this process in different rooms baths

Materials suitable for baths

A bathhouse is a place where all structural elements constantly endure temperature changes and their contrasts. In conditions of moist heat, the evaporation of many synthetic substances and polymers is activated; tactile contact with heated building materials can result in burns.

These operational features determine the mandatory technical characteristics of materials used for insulating baths: thermal conductivity, moisture resistance, fire safety, natural components, environmental friendliness.

In order for the bathhouse to become a place for improving health, it is preferable to assemble a log house made of wood Siberian forests (cedar, larch, pine) harvested in winter. For cladding premises, hardwoods are chosen that do not release resins and essential oils when heated.

Popular insulation materials have been popular since ancient times. organic and natural: clay, peat, expanded clay, flax fiber, moss, jute, tow.

New synthetic- non-flammable mineral insulation, magnesite boards, gypsum fiber, polystyrene foam, honeycomb.

Waterproofers often used are bitumen mastic, glass hydrosol, euroroofing felt (except for use in the steam room), polyethylene film density 140 microns.

Optimal types vapor barriers for bath rooms are - kraft paper, aluminum foil, and at the same time insulation - foil foamed foam (NPP polypropylene laminated with foil).

Sequence of insulation work

- The very first stage of insulation will begin during the assembly of the log house, when between its elements you will have to lay an organic fiber heat insulator: tow, jute, flax wool, dried moss or a combination thereof.

- When laying a bathhouse, you can take measures to insulate the floors, especially if they are constructed of concrete. In this case you will have to do ground work for leveling, filling with sand and expanded clay; pouring the base floor.

- How to insulate the ceiling and walls of a bathhouse? Insulation is carried out from the inside and outside, but after the process of shrinkage of the structure has been completed.

- Measures for insulating windows and doors, external and internal cladding work to preserve heat in the bathhouse premises.

Only in six months is it possible complete this process using a hammer and caulk (a special spatula), carefully sealing the ends of the fibers into the seam. True, synthetic sealants have also appeared for this purpose, but for a bath it is especially important to maintain environmental safety under conditions of heating and evaporation.

Insulating a wooden bath from the inside

How to insulate a bathhouse made of logs (timber)? You should start with insulating the ceiling, it is he who takes on the first wave of heat and steam. The heat-insulating layer must be significant (in the steam room - up to 15 cm) with a mandatory vapor barrier membrane: for the steam room it is foil, for other rooms - kraft paper or thick polyethylene. It is also enough to upholster the walls in the soap bar and dressing room from the inside with clapboard or wooden dies made of wood hardwood(aspen, linden).

- Ceiling insulation algorithm:

- Line the surface with clean roll paper and overlap it wooden ceiling(secure with tape and stapler);

- we attach bars across the ceiling that exceed the thickness of the insulation used (preferably rigid mats made of basalt wool or slag fiber); for the ceilings of the dressing room and soap box, expanded clay, sand and even sawdust mixed with clay can be used as insulation;

- the mats are laid out in the crate;

- the next layer is aluminum foil, the joints of which are taped;

- the sheathing is attached to the foil as a basis for the front cladding;

- if the ceiling of the bathhouse will be used as the floor of another room, then 3 cm of cement-sand screed under the wooden flooring is placed on top of the insulating layer.

First way:

- bitumen mastic is applied to the concrete surface;

- after it dries, the floor is covered with thick plastic film;

- next comes installation ceramic tiles or underfloor heating installation.

Second way:

- a layer of 15 cm of mineral wool is laid;

- covered with euroroofing felt extending to the level of the plinth;

- logs are treated with an antiseptic;

- subfloor is laid;

- finished wooden floor made of tongue and groove boards.

The first method is more suitable for the utility rooms of the bathhouse, the second - for the steam room.

We insulate the bathhouse from the outside

Insulating does not only mean protecting from blowing. Insulate - ensure conditions for maintaining a stable thermal regime

indoors.

Insulating does not only mean protecting from blowing. Insulate - ensure conditions for maintaining a stable thermal regime

indoors.

For log cabins or when building bathhouses in areas with mild winters, it is quite enough to carry out external insulation of the walls to protect the bathhouse from heat leaks. Inside there is only finishing made from natural materials.

At the same time, it is possible to insulate the walls from the outside immediately after the shrinkage of the log house, based on the thickness of its elements and the density of the crowns.

The attic is subject to external insulation:

- the ceiling is covered with glass hydrosol;

- it is filled with expanded clay, slag, or mineral mats are laid over the insulator;

- a reinforced or non-reinforced screed is made on top.

For external wall insulation ventilated facade technology is used:

- a sheathing frame is created along the width of the sheets (mats, slabs) of insulation, exceeding the thickness of the sheets by 3 cm (for the ventilation gap);

- the insulation is laid in the sheathing structure from bottom to top:

- the diffuse membrane is attached to the sheathing with a stapler;

- Facades are faced with varnished lumber, false beams or colored siding.

Requires special attention insulation of the basement, where the cooling of the walls, especially during the cold period, occurs especially intensively.

To do this, formwork is installed around the perimeter of the structure from boards up to half a meter high and 30 cm deep. The formwork cavity is lined with any waterproofing material and filled with soil or expanded clay. The top is covered with a board to prevent erosion by rainwater.

Additional insulation

Additional insulation windows are subject. To preserve heat, it is preferable to make them small and at the bottom of the wall. The most reliable are triple-glazed windows, provided they are tightly inserted into the wall openings and seal the cracks.

High thresholds and small door frames with a low ceiling will also help preserve heat in the room. The entrance from the dressing room to the soap room and steam room should not be located on the same axis.

The dressing room should have a door insulated with thick felt vinyl covering. The insulation should be 10 cm larger than the dimensions of the door. It’s even better if the entrance to the dressing room is equipped with a closed vestibule.

The efforts and costs of insulating a bathhouse depend subsequently the cost of firewood to heat it, and, finally, its safety and durability.