Winter came and I had to do something with the bike so as not to fall on the ice. I could buy ready-made studded bicycle tires - it would cost me 4-5 thousand rubles. Not only because of the thirst to save money, but also from the eternal desire to do something with my own hands, I decided to make winter bicycle tires myself.

Purchased: 2 budget tires for 250 rubles each. each; 400 pcs. 13 mm. self-tapping screws (about 100 rubles).

Tires were chosen with large “teeth” so that self-tapping screws could fit comfortably into them. The tire had a total of 80+140+80 teeth. I didn’t want to screw in 300 self-tapping screws, so I inserted one screw into the side rows. As a result, about 190-200 screws were inserted into each tire. This made the tires about 200 grams heavier.

So, the tires have been purchased, and the screws too. We need to get to work. First you need to make guide holes in the tires. Without them, the screws will often go crooked and come out in the wrong place. It is very important that the screws “peek out” from the center of the “tooth” - this will extend the life of the tire. To do this, I took a drill and started drilling holes. It was, to put it mildly, difficult, so I came up with new way: I clamped the nail with pliers, heated it over the fire and used it to make holes in the tires. It was no longer difficult, but it still took a lot of time. And then a brilliant idea came to my mind - making holes with an awl! I didn’t have an awl at home, so I had to buy it. Making holes with an awl is the best option.

The holes are ready, it's time to screw in the screws. I bought 13 mm self-tapping screws with a press washer. It is very important to buy with a press washer, because... only they have a fairly wide “hat”. I screwed the screws into the tire with a regular screwdriver. I didn't turn the tire inside out. The main thing is that the screws are screwed in evenly. There is no need to plant them with glue. The self-tapping screw needs to be screwed in so that at the exit it slightly bends the rubber under itself with the thread.

Here's what I got:

On last photo It can be seen that on the side rows the screws are inserted one after another. In the center, too, sometimes there are empty teeth, the order there is: 1-2-1-1-2-1-1-2-1, etc.

The screws are screwed in, let's move on. Now they need to be sharpened. I didn't have a sharpener, so I asked a friend to sharpen the tenons. The self-tapping screws were very strong and the sharpener was more likely to wear off than they were. But, anyway, we managed to sharpen them. One tire had slightly longer studs; I put it on the front wheel, because it carries less load and the quality of handling depends on it. The side row of screws can be ground less (the main thing is that they are not sharp), because they will only work when turning. A tire with machined screws looks like this:

This is the front wheel. The spines on the back are one and a half times shorter.

The screws are screwed in and ground, but that's not all. To prevent the screw heads from damaging the camera, you need to make a lining. To do this, I brutally cut two cells - one old and one, dare I say it, new. Now you can assemble the wheel. When placing the camera, be careful not to scratch it on the spikes.

Yesterday I tested my homemade winter bike tires, riding about 25 km on snow and about 35 km on asphalt. When driving on asphalt, a rather loud noise is created, but this cannot be called a big drawback. When driving on snow and ice, the tires showed themselves to be the most the best way- while my friends on regular tires constantly fell on the ice, I drove absolutely without bothering, as if on asphalt :) If you compare studded tires with regular ones, albeit with a bad tread, during emergency braking the difference is simply monstrous. Heaven and earth! With studded tires, when braking sharply at high speed on ice, it does not skid at all; the studs leave a deep mark on the ice.

There is only one drawback - it is difficult to maintain a high driving speed and a little more difficult to drive in general. You can feel this when driving on asphalt, but driving on ice/snow is a real pleasure.

As I already said, yesterday I had to drive about 35 km on bare asphalt. A friend who has much more experience said that when I get home I will have to change the tires, since the studs will wear off from the asphalt. But it turned out that the screws were practically not worn out. They were just sharpened and became less sharp, but the length remained the same. However, it’s worth noting that it’s not necessary once in a while - I was just lucky with the purchase of high-quality screws. In general, although it is not advisable to drive on asphalt with such tires, it is possible if you do not maintain a high speed.

And finally, a short video:

Bicycle lovers often don’t get off their bikes even in winter. Anyone who has ever tried to drive on ice will appreciate the advantages of studded tires. Only the price for it bites. For a normal studded tire they ask from 1000 UAH. Here we reviewed the famous Nokian WXC-300.

What if you make it yourself? Why not. Let's make studded tires for a bicycle with our own hands.

We take a certain amount of banknotes and go to a bicycle shop. You can read reviews of some stores here.

We choose an inexpensive one so that you don’t feel sorry for throwing it away if something doesn’t work out as planned. But at the same time, it should be wide enough and have a large tread.

Then we go to hardware store and buy self-tapping screws with a flat head. Their length depends on the tread depth of the tires. It is necessary that the end of the screw protrudes 1-2 millimeters. I chose the ones in the photo. I bought two sizes 10 and 12 mm. Which I didn’t regret later (I’ll tell you later).

In general, you need to measure the thickness of the tire before buying studs. How to do it? The easiest way is to pierce the tire with an awl at the future location of the spike and measure the awl. But I realized it after returning from the hardware store.

Next, we pierce holes with the same awl at the locations of the spikes. These places can be seen on branded spikes. It is better to do the puncture with outside, this allows you to clearly see where the tip of the spike will come out later. And screw in the screws. I repeat that they should protrude 1-2 mm from the tire.

Since I had two sizes of screws, I screwed the longer ones into the sides. Which I didn’t regret later. They help well when cornering. The main thing is not to touch the fork.

Thus, one tire requires about 100 studs (depending on how often you install them). This slightly increases the weight of the tire, but for budget option it's not scary.

Studded bicycle tire with your own hands

Studded bicycle tire with your own hands Then you need to place a gasket inside the tire between the screw heads and the tube so that the heads do not rub against the tube. It can easily be cut from an old camera. But it’s still better that the gasket is made of more hard material. For example, there is an idea to make it out of leather. Cut old shoes or boots)

Well, that’s all, you can put on studded tires and go test it out. I skated on this for two seasons. The flight is normal.

When I decided to stud a bicycle tire for the first time, one of the main reasons was the lack of winter bicycle tires on sale, or rather, they were very rare, and therefore there was no choice of options. But now they are on sale, and there is some choice, and you can probably buy any of them in online stores.

But looking at the arrangement of metal and rubber studs in bicycle tires, and understanding how and where there is a desire to ride in winter, my mood did not improve. It’s as if the employees of tire manufacturing companies who come up with products care about their products from too idealistic positions. Either asphalt and smooth ice, or compacted snow alternately with a snow-free road. And the studs are specially made so that they are more likely to get lost on hard surfaces, and you would have to buy another bicycle tire.

As a result of the reasoning - spend money on what is available or do what is much cheaper, but exactly as needed, I chose to do it.

Choice of base - tires

First I decided on the parameters - what the tire should be. And taking into account the previous experience of studding old ones with a partially worn tread, I decided that only a new one and not a random one that can be obtained for free (or almost for free), but chosen from catalogs, or from those suitable ones that are on sale. As a last resort, I decided to wait for the one ordered from the online store, but the one that would be more suitable.

- - it must be folding, since it is much easier to remove and install in the cold than with a wire frame - tires with an aramid frame are softer and more manageable. Yes, and pierce with an awl, drill, holding the direction of piercing and drilling, under the right angle easier, just like screwing in a tenon screw. If the tire can be turned flat. It is easy to press it with a clamp to the plane of a workbench or plywood (board).

- - must be with Kevlar cord, since puncturing a tire in the cold and then gluing it is not an easy task due to that very frost. I already had experience of a tire bursting in winter - I drove over a broken section metal fence with a protruding rod that is not visible under the snow. Then I sealed not only the tube, but also the tire - the gap was one and a half centimeters. The cold procedure took more than two hours. The fire had to be lit in order to glue at a positive temperature.

- - The main point is the location of the rubber studs of the tire, because metal studs will have to be installed in them. So that the height is no more than 4 mm - less than the branded winter ones by 1.0 - 1.5 mm, and the location and quantity would allow driving on hard surfaces with less losses. And so that when turning and passing inclined ice surfaces, the spikes end up in the place of the most advantageous application of forces - holding abilities. And it is imperative that the spikes be located more often along the contact path, for less mechanical losses when driving on ice.

- - dimensions of the rubber studs of the tire. So that the size of the tenon, along or across, should not be less than 8 by 8 mm, since it will be impossible to hold the tenon under load - the rubber tenon will tear in the direction of the load on the metal tenon.

The tire we found and liked in all respects had 444 studs measuring 9 by 11 mm and 8 by 11 mm, 4 mm high, located in the best way for the planned winter rides on ice, asphalt and rocky dirt roads.

|

|

Shopping fasteners I had to spend a long time, because what some offered could be worse than what could be found somewhere else. Only two sellers had visual stands to select screws, but for clarity, there were only one, two standard sizes, and not all that could be on sale. And I had to search the sites for links to articles by home-made people who were ahead of me in this idea.

In all the articles I read, self-tapping screws with sharp ends of screws or washers with curved pointed edges (homemade or furniture ones with a threaded recess - a washer-nut with horns) riveted with rivets or regular rivets were used. Both of them have one feature - to tear and tear everything that they touch or drive over - clothes, wallpaper, linoleum, etc. Another reason for refusing washers is that those for furniture need to be secured with a screw with a flat washer, but even with a thread locker they can be easily lost. But the main thing is that it is impossible not to get hurt when putting on or taking off such a tire, even with gloves or mittens made of strong, thick leather. An attribute that you will definitely need to take with you along with other tools if the spikes are so sharp. How to harden them is also a problem. And the losses when moving with such washers are large. In general, no to washers.

In the end, the choice was made on self-tapping screws with a washer head, hardened, galvanized with a drill tip.

The drill ends of these screws do not scratch your hands and do not cling to fabric, fleece, or down jackets. They don’t stick into linoleum, they don’t tear wooden surfaces under light load. But since the tips are made for drilling metal, they are more hardened (harder) than ordinary self-tapping screws. I tested it by trying to scratch the glass with self-tapping screws and sharp regular drills. With drills I was able to scratch with less pressure and right away.

|

|

|

|

The sizes were suitable - 7.5 mm, 9 mm, 13 mm, and 16 mm in length, and diameters - 3.8 mm and 4.0 mm, which were quite suitable for installation in tires at different thickness rubber.

True, the 2 smallest sizes had caps with a diameter of 7.75 mm and without washer-like extensions. The rest have head-washers with a diameter of 10.7 mm. For some reason, sellers call them prewashers.

Since the studs were found and purchased, I could also buy the tires I liked, which were waiting for me at the Trial-Sport store.

Combining theory, guesses, other people’s and one’s experience into a single whole

|

|

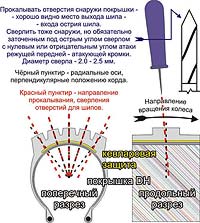

First I had to think about the installation method - screwing in the tenon screws, how to drill and pierce the tire so as not to damage the cord. Trying on a cut piece from an old tire, cutting along the drilled hole different angles and with different speeds, drills different diameters- from 1.0 mm to 4.0 mm, and changing the sharpening, I came to the conclusion. You need a drill with a diameter of 2.0 mm - 2.5 mm, sharpened at an angle of 45 degrees or more, with a zero or negative angle cutting edge, the attacking part of the drill. Best indicator was when drilling with such a prepared drill, but in the opposite direction, as when unscrewing, the cord threads were not damaged at all. But even with right rotation, the results were not bad - the cord broke in isolated cases.

The technology is this: first, use an awl to pierce the tire where the spike will be installed. At an angle where the tenon is installed. Pierce from the outside so that the awl sticks out 15-20 mm inside the tire, so that you can see the location and angle - the direction of the hole. Take a drill with a drill and the direction of rotation switched to the opposite direction. The maximum rotation is no more than 1000. It is more convenient if this cordless drill with speed control by trigger. Note the location and direction of drilling, pull out the awl and immediately drill into the resulting hole. Put the drill and drill aside, take a second drill - an electric screwdriver with a Phillips screwdriver installed in the chuck - a pin that matches the number of the cross for the screw-drill. Place the screw-drill on the tip of a Phillips screwdriver (pin) and screw it into the hole at an angle of drilling - piercing with an awl. Check that the tenon screw drill comes out exactly in the right place, marked with an awl. And do the same 443 more times, and then for the second tire the same amount - exactly 444 identical procedures - “Chinese labor”. A little “trick”, so as not to pierce the tire for each stud separately, was to puncture as many holes as the number of studs intended to be installed on a given day (work shift). Then he stuck parquet nails into the resulting holes, and took them out only before drilling, one at a time. Then he again inserted nails into the resulting holes, but thicker - 3 mm thick, immediately after drilling. And when he had drilled enough for the day, then he took out three-millimeter-thick nails one at a time before screwing in the tenon screw. So the holes did not “disappear” - they did not tighten, and it was faster and more accurate than repeating all the procedures with each spike.

First, a row of outer ones, at appropriate angles, pierced and inserted parquet nails (they are inserted easily) - you can immediately see whether the holes are straight and correctly marked by the protruding row of nails. Then the other extreme row, and then the rest along the rows. But not all around, but a section - a sector into which the tire was divided, like on working days. Observing accuracy and attention, each stage of work can be easily visually controlled using evenly placed nails.

The work listed above took approximately 30 working hours - two weeks in the evenings.

It could be faster, but I worked out the control technology, and it’s already beautiful - the result of the work is visible and predictable.

|

|

Attention - you need to pierce the tire with an awl once for one tenon, accurately marking the location of the hole according to the drawing, taking into account the angle along the red dotted line - 3-5 degrees from the black dotted line, no more.

Tire 26 by 2.25 inches, used stud screws different sizes- the middle row is the smallest, blued, then - slightly larger galvanized, and on the outer rows the largest with a pre-washed cap.

Close-up - 26 x 2.35 inch tire. It can be seen that the screws are screwed into the outer rows at an angle favorable for holding the ice. All the spines are the largest, with a pin-shaped cap.

I called a trial specialist I know and asked: “Are there any unnecessary thick rubber tubes left with the nipple torn off?” It turned out that there are as many as 3 pieces. It was from these chambers that I cut out the strips. I cut the sides in the middle and used the outer part. Two chambers with a wall thickness of 1.5 mm and one with a wall thickness of 3.5 mm - heavy, the whole chamber weighed 600 grams, like a tire.

Thick-walled chamber, cut off in the middle of the sides. For insertion into the rear studded tire - protects the bicycle tube from the heads of the studded screws. There is also more load in the middle rows of tenon screws, small-diameter caps are more prominent.

I installed a thick-walled strip under the rear tire, and a thinner one under the front. One thinner one is a spare one. Inflatable bicycle tubes, used by Schwalbe, priced at 240 rubles - regular, but made of rubber High Quality. I bought it at Leader-Sport, on the street. K. Marx.

|

|

| Front tire from the inside |

|

|

| Rear tire from the inside |

Rear tire from the inside, visible inner tube with marks from the heads of the stud screws. There were no breakthroughs, there was no hint of abrasion - the “gaskets” can be thin.

Tests

This most exciting and interesting thing happened from the Tyomnaya Pad station and while crossing Lake Baikal on the ice.

At first, of course, I was driving to the central passenger station on the asphalt.

The first impression is the sound, like a dog running along linoleum or parquet with its claws extended, but stronger. We are driving with a friend whose wheels have no spikes. But since there is no ice, we drive quickly and seem to be stress-free, although we are careful not to slip and away from the cars.

The trials of skating on the skating rink were surprising, but only for a moment - normal skating, turns and braking without problems. But there were no cars with pedestrians at the skating rink.

So no unusual impressions appeared. I tried to brake sharply and turn around - it was fine. It seemed that without spikes my friend was less confident, but this did not seem to be some kind of indicator. We're going by train to Tyomnaya Pad. How will it be there?

We arrived, looked down at the path and... drove off. At first, slowly, and then somehow inexplicably confident and taking more and more risks. Braking with the rear wheel, helping and sometimes dragging one foot in the snow, like motocross athletes, and even accelerating and jumping in some areas. Creepy. Suicide slope.

I look around - my friend is gone, his bike is gone too. I had to dismount and search. It turns out that he brakes with the rear wheel and discovers that this has no effect on steep slopes track, began to slow down with the front one, but this did not help on the snowy path. He began to accelerate and ran into a piece of soil bare of snow. The front wheel, locked by the brake, and it had rim brakes, stopped them both and threw one, over the handlebars of the other, down the slope. But somehow silently - he didn’t have time to get scared and scream. Then the bike flew away too. One lies below, silently in the deep snow, and the other, rotating its wheels in an inexplicable position, ten meters to the side. The one without wheels responds with some phrase from an anecdote and unprintably about a close relative. The snowdrifts received both without defects - they flew next to huge stones and lying tree trunks.

Watching the action described above, for the first time I became proud of my bicycle studding. After all, I never slipped even once, although I was afraid a lot.

Further down, on the Angasolka River, there was a super test. I drive down the path to the bridge, and from there onto the lumpy ice - snow on top, a layer of wet slush underneath, and ice at a depth of 5-10 cm. I reached the tree, looked back, and my friend was walking around this ice disgrace along the slope with a bicycle on his shoulder. He shouts that it is impossible not only to drive, but even to walk - it is slippery and wet. Once you fall, you will have to continue driving wet.

I let go of the tree and food, no sensations, normal driving, only splashes of sludge to the sides. I even liked it, I skated in different directions, because the ice on the river is lumpy and inclined, like a slope. Amazingly, no uncertainty, the ride is easy, like on dry and hard gravel. I didn’t want to go further, an absolutely unusual feeling from ordinary confident skating - you go easily, shift, accelerate, brake, but this is a very slippery and uneven place, more slippery than just ice. I haven’t walked through such places yet, but on the contrary, I avoided them.

While we were driving to Lake Baikal, out of interest I chose the opportunity to drive on the ice of the river, where it is under slush, wet, bumpy, or whatever - the driving is absolutely normal, there is no stress, so as not to slip. It’s easy to slide onto the ice and drive back onto the shore where the trail runs.

On the shore of the lake, several skiers took skis and poles in their hands and went to the snow drift so that they could ski along it to Slyudyanka.

Looking at the absolutely flat and smooth ice, I was a little confused - how would it go? But having driven onto it, I heard the noise from the thorns and that’s it... no other feelings - as if smooth road. I accelerate, I brake, I make such turns that I almost fell several times, I jumped and bucked as best I could and... NOTHING. It’s even strange, because you can ride on smooth asphalt in exactly the same way. I began to mock myself and my bike, but no amount of maneuvering or braking allowed me to slip or skid, either on the ice or on thin crust. True, I turned over the steering wheel several times, both straight and sideways. That day, only my friend had problems - he was driving no faster than 6-9 km/h, and then on low tires. At normally inflated speeds, even 3 km/h, the problem was falling and slipping every 5-10 meters. I can’t imagine how many bruises and bumps I brought home. True, I brought it too - from flying over the handlebars. One of the flights was caused by sharply braking with one rear wheel.

The main impression is one thing - NO IMPRESSIONS - normal skating without problems and uncertainty. Self-studded tires “hold” on ice or a dense snowy road much better than new tires on clean summer asphalt.

Another time, to the Angasolka River, I drove along the highway and gravel road for almost 20 km - I didn’t lag behind, even sometimes went ahead on the descents, although everyone with whom I rode in a small “gang”, except me, was riding on branded spikes.

We went down to Lake Baikal past the village of Angasolka along a frozen dirt road. I'm crooked and wet ice on the Angasolka River, and those on branded spikes, along the trail. The owners of the “company” tried it, one even fell, and stopped taking risks - driving on wet ice, and on Lake Baikal they didn’t risk sharp maneuvers, but in a straight line they could race with the company guys on equal terms. True, at the “firm” they could afford to press the rear brake sharply and strongly - the rear wheel skidded slightly to the side, and I could fly over the steering wheel.

It’s a pity that I didn’t take a camera and there are no pictures of those tests. Twice I rode in company with Diagran (who knows) on his spikes, both on the highway and on the snow and ice of Baikal - you can’t keep up with him even on highways on asphalt, he drives on ice at 35 km/h on ordinary branded spikes - a monster.

On the train, when setting up the bike, there was no fear that clothes or fleece gloves could be torn on the homemade spikes, was taken on purpose.

By spring, it became noticeable how the drill bits of the tenon screws became dull and became semicircular, but this did not affect the holding power on ice and compacted snow. True, due to the fact that the spikes have become a little shorter, it seems to be easier to drive on asphalt and ice. And also - the more dull the drill bits become, the slower their abrasion occurs - the contact surface area increases. It becomes approximately equal to the area of hardened studs, like branded bicycle tires, without Pobedit inserts. In the first winter I rode about 700 km with studs, I don’t know more precisely, since the bicycle speedometer “died” after 600 km. On asphalt and concrete with ice, it turned out to be about 100 km, about another 250 km on gravel and dirt roads, the rest about 400 km on ice and dense snow.

I think that with my use, it will be enough to drive at least 1500 km before replacing some studs.

Theory confirmed by practice

The proposed stud installation angle was derived from the assumption that the greatest shear load on the stud is during braking. And in order for the spike to “bite” into the ice in the best way, it must be installed at a negative angle to the plane of the support when moving forward.

The side spikes are also at a negative angle to the plane of support from the corresponding side, as when driving on a slope or when turning at speed. And since, under shear load, the studs will deflect in the elastic rubber of the tire, this deflection will be smaller due to the greater thickness of the rubber behind the stud and the greater elasticity of the thicker layer of rubber.

I did not glue the gasket between the bicycle tube and the heads of the self-tapping tenon screws, since the gluing will not be tight, and water and dust will get into the leaks - dirt will be in it, and inserting and removing this gasket is not particularly difficult.

How will water get there?

Let's say you had to drive in wet places, and then remove the tire and tube in a warm place - water from the internal volume of the rim will flow into the tire.

And you need a lot of glue - 2-3 full tubes per wheel. With mediocre results - poor quality gluing. After all, the raised caps will interfere with the ability of the rubber of the cut tube to stick to the inside of the tire. And with a thick layer of glue, “chewing” sounds will be made, which happened when I glued bicycle tubes to road bicycle wheels on an excessively thick layer of glue - poor quality gluing. And since high-quality gluing cannot be achieved, then why do it poorly? After all, if you have to replace any spike, you will still have to tear off the glue.

I hope that what happened in the end, and which gave me the opportunity to be convinced of the correctness of my guesses and the work I put in, will help those who are not afraid to spend work, accuracy and attention for the final result - riding a bicycle where it was impossible before, but with These tires are safe and pleasant.

Today we will talk about how to install studs on a bicycle tire yourself to make winter studded bicycle tires. We will also consider installation techniques homemade spikes DIY bicycle tires for cycling in winter

A bicycle, of course, means riding more in the warm season, but some extreme cycling enthusiasts do not leave their “iron horses” alone in the winter, organizing winter rides in nature or simply using them as a regular vehicle.

Operating a bicycle in winter requires not only excellent physical fitness of the cyclist, but also places special demands on the bicycle. So, a few useful tips on winter use of a bicycle:

· Be sure to install winter studded tires. If you frequently drive on ice or packed snow, you need tires with at least 200-350 studs; for driving on city streets, there may be fewer spikes - from 50 to 200 pieces.

· If the bicycle only has caliper brakes, then at least one of them (front) must be replaced with disc brakes. The thing is that V-brake brakes operating on the rim clamp significantly lose their effectiveness in the cold due to icing of the rims. The wheel can make up to 10 revolutions from the moment you press the brake. What kind of safety can we talk about when a bicycle travels a distance of 20 meters in 10 revolutions? In cold weather, disc brakes also work worse than in summer, but are still significantly more effective than V-brake brakes.

· When driving on winter roads, the chain is sure to become clogged with dirt and road reagents. After each ride, be sure to clean and lubricate the chain.

· When driving in snow, the sprockets and gear shifters become clogged with snow very quickly. It is recommended to periodically stop and clean the gear shift mechanism.

· If there are cracks or chips on paint coating bike, paint over the damaged areas, otherwise the rust will corrode the frame, and in the summer you will no longer have anything to ride on.

· The bushing and carriage seals “harden” in the cold, letting dirt and other nasty things in. We recommend disassembling and replacing the grease of the bushings and carriage once every two months.

· It gets dark very quickly in winter, so be sure to install a red flasher and reflectors on your bike to indicate your presence in the dark, and install a headlight on the front, preferably an LED one.

Many cyclists ask themselves the question in winter: whether to switch to studded tires or not. One of the decisive factors against studs on a bicycle is the considerable price of high-quality winter tires. Just one bicycle tire with spikes can cost five thousand rubles - people are not always willing to spend that much on bicycle tires.

But by the way, such tires are worth the money - the studs reliably bite into icy areas, allowing the bike to maintain its trajectory.

No desire to buy? You can do it yourself

Let’s say right away that it’s unlikely that you’ll be able to maintain the roll-up when studding yourself, but decent contact with the ice surface can be achieved quite easily.

What do we need for self-made studded bicycle tires:

An old tire with a high tread (a completely worn one will not work);

- awl;

- a couple of hundred self-tapping screws with a press washer;

- silicone or shoe glue;

- old bicycle tube;

- pliers;

- screwdriver;

- file.

All necessary materials found? Begin!

Decide what kind of drawing you are going to do. It is optimal for most cases to insert the spikes in three rows - on the sides and in the center. You can do without a center to maintain the roll and give the rubber the properties of a winter grip for turns and in narrow icy tracks.

You can also stud in four rows - this is especially reasonable if the checkers in the tread have an even number.

Having decided on the patterns of the studs, mark the punctures along the centers of the lugs (bumps) of the tire.

Turn the tire inside out and start screwing the self-tapping screw into the pierced hole - a small part of it should come out right in the center of the lug. The task is tedious and long.

On next stage Let's start making a fur coat. For this we need an old bicycle tube. Cut it, lay it out inner side tires (not to the very edge of the cord), measure and align everything again and start attaching it with glue. The purpose of the fur coat is to protect the working bicycle tube from cuts from the heads of the self-tapping screws.

The next stage involves grinding down the screws to an acceptable level. You can leave the side ones, but you will have to cut off the radial spikes. Leave the edges of the radial screws protruding no more than 1-2 mm. With the sides - to taste.

What to cut with? – wire cutters, pliers, file, grinder. Using wire cutters or pliers you will make a rough cut, and with a file you will level it to a condition close to what we see on factory tires.

That's all.

Features of self-made winter bicycle tires

Not the most ideal roll;

- Quite a massive mass of the structure;

- An archaic stud, inferior to what we see on factory tires;

- Cheap and cheerful!

Video instruction

Is all this necessary?

The Vashen spike is for those who race downhill, or participate in country racing, or on bicycle trips.

It is customary to clean downhill trails before skiing, but this will not make the ground softer - the stud increases traction with the frozen ground, this is important and you can feel it.

In winter country racing without spikes it is objectively more difficult to work at full strength. As long as the snow is soft, it’s good, but the sections on the slopes are different.

In cycling tourism, the spike is safety. When you are riding along the trails, think about how dangerous it is for a wheel to go off on a sudden icy bump, and even off the trails - in the forest, in snow-covered areas, bicycle studs save lovers of winter cycling trips.

Buy good bicycle tires for winter, or make them yourself, as described above in the article. There will be less pressure, but there will still be more advantages to using it.

Cycling is a pleasant pastime for many people. But for those who like to ride a bike in winter period Other studded tires are available. Next we will need a tool: a good, suitable screwdriver for self-tapping screws, a 7 (8 mm) screwdriver or drill, a drill (2-3mm chalk, an awl, a tire spacer. We mark the tire, the places where the spike will sit. You can use chalk or a marker . We mark evenly. We take into account the fact that large quantities studs increases the weight of the tire, and with too little studs the necessary grip will not be provided. Needed here creativity. You should also not forget about the weakening of the tire due to the cord breaking with a drill and screws. We drill the marked places with a drill with a diameter of 2-3 mm. We insert between the sides.

I “made” the tires in one evening using a screwdriver, by eye. Between the tube and the tire there is a gasket - a strip of adhesive in one layer. The self-tapping screws are the smallest, 2.5x10. Impressions: the tires are extremely inconvenient to install, the new screws are prickly. On ice and compacted snow, traction is very good. From the icy rut the motorbike is very small angle leaves without problems. It holds the road when braking and turning. It is impossible to drive on loose snow - the resistance force is too great. The photo shows the wheel after 400 km. Half is on ice, the other half is on asphalt. #eleven.

Use a screwdriver to press the screw into the slots, with the head on the outside. We tighten it so that the first turn of thread appears above the nut. We visually and manually check that the tire is well compressed by the stud head on the inside and the washer and nut on the outside. And so with each thorn. Be careful, the ends of the screws are dangerous! The following may be harmed: body and limbs, clothing, parquet flooring, varnished/polished objects and particularly sensitive animals! Do not forget that at speed and when rotating, such a wheel can seriously injure both its owner and those around him. When assembling the wheel between the tube and the tire. Today I decided to renew the worn out screws on the rear wheel of my bicycle. Why only in the back? Because they haven’t worn out on the front one :) Although the front wheel is mainly responsible for handling, I wanted to update the screws on the rear one in order to get rid of slipping and skidding on ice.

So, although the self-tapping screws on the front wheel have worn out a little, they still need to be rolled and rolled, and I don’t see the point in replacing them, they work well. On the rear wheel, the screws have worn out almost completely and they have very little effect: I began to slip a lot on ice, and the rear wheel often drifts off. There were no falls, but control over the road weakened.

I would like to talk in more detail about how self-tapping screws wear out. Only the center row is sewn. The side rows work very rarely, so they hardly wear out on both wheels. The front wheel is lightly loaded, so they practically do not wear out there. On the rear wheel everything is more serious. Let's imagine that we have a wheel with new screws. After 10-20 km of driving on asphalt, the screws will noticeably wear out. Then the wear rate will decrease. After 40-60 km of asphalt, the screws will protrude from the rubber just a little, but will still provide good grip on ice. After this, the wear rate will be reduced even more, and only after 100-200 km of asphalt will they wear out so much that they stop working. Therefore, do not be alarmed if you notice that after a few kilometers asphalt pavement The brand new screws have noticeably worn out :) I've driven a little over 400 km this winter so far and only now I decided to stud the tires again. Moreover, we must remember that the winter of 2011-2012 until mid-January was practically snowless and I had to drive almost exclusively on asphalt. I think if the winter had been normal, my thorns would have lasted until spring.

I will also mention gaskets. After the tube was cut through with screw heads 3 times, I decided to take extreme measures and made a gasket between the tube and the tire from three old tubes on the rear wheel, and on the front wheel from an old semi-slick tire. The bike became noticeably heavier, but I got used to it and can now maintain a fairly high speed.

So, this is what old worn out screws look like. They hardly help anymore:

And this is what the new ones look like, just screwed in. They look scary, but you only need to be afraid for the linoleum :)

Replacing screws is not difficult. I just unscrewed the old ones and screwed in the new ones. Of course, I didn’t touch the side rows. It took less than an hour to unscrew the old screws. It took a little over an hour to screw in the new ones. The rubber, by the way, was practically not worn out and the new screws fit quite tightly. I also want to draw your attention to the fact that although I use the most budget tires (250 rubles per piece), its condition can be assessed as excellent, despite the fact that I drove at least 300 km on asphalt and only a little more than a hundred on snow (it’s winter , damn it, snowless). Those. self-tapping screws reduced tire wear when driving on asphalt.

Last time I asked a friend to sharpen my screws to the required length. I didn’t want to disturb the person a second time, so I decided not to grind off the screws at all. As you can see in the photo, they protrude from the rubber by 0.5 cm

I hoped that I would drive a few kilometers on the asphalt and they would wear out. Actually, that’s almost what happened, only they didn’t wear off, but broke off a little at the ends. After just a couple of (quite heavy, by the way) kilometers of asphalt, they were without sharp ends, and after 10 km of asphalt and 20 km of snow (well, snow doesn’t count), the screws are quite suitable, slightly hypertrophied spikes that hold perfectly on ice and protrude just 1.5-2 mm. Now that they have become shorter, their wear will be noticeably reduced and you can drive safely

Actually, the result is this: there is no need to grind down the new screws, you just need to drive literally 2-3 km on asphalt.

Studded tires for a bicycle allow its owner to enjoy riding a bicycle in ice and snow, without fear that he will not be able to cope while moving and will fall on a bad road. After all, the road is often simply unpredictable during winter driving.

Studded tires are similar to car tires, with a durable metal tread that is located on both sides of the tire. It makes it possible to drive on icy surfaces without problems, but only if the tires are not overinflated.

The studs on the tire themselves are various shapes:

- pointed;

- flat.

In addition, studded tires come with different numbers of studs.

One type is double-row tires. They are located on the sides. When the wheels are well inflated, they practically do not come into contact with the surface, only when turning. This applies to weather conditions when there is no ice on the asphalt surface. But if you need to drive on an icy surface, the tire should be less inflated. And the weather will work exactly those side metal spikes that are necessary for contact with the slippery surface.

Another type is four-row tires. They are similar to double-row tires, but the difference is that they also have two additional rows of studs. That is, the number of studs on the tire has been increased by one and a half times. They are more powerful and make it possible to move comfortably where there are no normal roads. But first of all, they are designed for driving on icy surfaces, but at the same time making it possible to drive on roads.

Important when using this tire:

1.do not carry out strong pumping. And then the cyclist will not care about steep turns and descents.

2.And then this makes it possible for the tire to have good grip on a slippery surface.

3.No sudden braking and studded tires will last quite a long time.

And after installing studded tires, you need to go through the break-in process. But this must be done very carefully. This is necessary in order not to harm the studs and the tire themselves. The running-in process itself is carried out on asphalt and for an hour with the bike moving slowly. This will provide the studded tire with more long term service in good condition and without loss of studs. And then any bike ride will be a joy, even in winter.

Winter came and I had to do something with the bike so as not to fall on the ice. I could buy ready-made studded bicycle tires - it would cost me 4-5 thousand rubles. Not only because of the thirst to save money, but also from the eternal desire to do something with my own hands, I decided to make winter bicycle tires myself.

Purchased: 2 budget tires for 250 rubles each. each; 400 pcs. 13 mm. self-tapping screws (about 100 rubles).

Tires were chosen with large “teeth” so that self-tapping screws could fit comfortably into them. The tire had a total of 80+140+80 teeth. I didn’t want to screw in 300 self-tapping screws, so I inserted one screw into the side rows. As a result, about 190-200 screws were inserted into each tire. This made the tires about 200 grams heavier.

So, the tires have been purchased, and the screws too. We need to get to work. First you need to make guide holes in the tires. Without them, the screws will often go crooked and come out in the wrong place. It is very important that the screws “peek out” from the center of the “tooth” - this will extend the life of the tire. To do this, I took a drill and started drilling holes. It was, to put it mildly, difficult, so I came up with a new method: I clamped a nail with pliers, heated it over the fire and used it to make holes in the tires. It was no longer difficult, but it still took a lot of time. And then a brilliant idea came to my mind - making holes with an awl! I didn’t have an awl at home, so I had to buy it. Making holes with an awl is the best option.

The holes are ready, it's time to screw in the screws. I bought 13 mm self-tapping screws with a press washer. It is very important to buy with a press washer, because... only they have a fairly wide “hat”. I screwed the screws into the tire with a regular screwdriver. I didn't turn the tire inside out. The main thing is that the screws are screwed in evenly. There is no need to plant them with glue. The self-tapping screw needs to be screwed in so that at the exit it slightly bends the rubber under itself with the thread.

The screws are screwed in, let's move on. Now they need to be sharpened. I didn't have a sharpener, so I asked a friend to sharpen the tenons. The self-tapping screws were very strong and the sharpener was more likely to wear off than they were. But, anyway, we managed to sharpen them. One tire had slightly longer studs; I put it on the front wheel, because it carries less load and the quality of handling depends on it. The side row of screws can be ground less (the main thing is that they are not sharp), because they will only work when turning. A tire with ground screws looks like this

The screws are screwed in and ground, but that's not all. To prevent the screw heads from damaging the camera, you need to make a lining. To do this, I brutally cut two cells - one old and one, dare I say it, new. Now you can assemble the wheel. When placing the camera, be careful not to scratch it on the spikes.

Yesterday I tested my homemade winter bike tires, riding about 25 km on snow and about 35 km on asphalt. When driving on asphalt, a rather loud noise is created, but this cannot be called a big drawback. When driving on snow and ice, the tires showed their best performance - while my friends on regular tires constantly fell on the ice, I drove absolutely without bothering, as if on asphalt :) If you compare studded tires with regular ones, albeit with an evil tread , during emergency braking the difference is simply monstrous. Heaven and earth! With studded tires, when braking sharply at high speed on ice, it does not skid at all; the studs leave a deep mark on the ice.

There is only one drawback - it is difficult to maintain a high driving speed and a little more difficult to drive in general. You can feel this when driving on asphalt, but driving on ice/snow is a real pleasure.

As I already said, yesterday I had to drive about 35 km on bare asphalt. A friend who has much more experience said that when I get home I will have to change the tires, since the studs will wear off from the asphalt. But it turned out that the screws were practically not worn out. They were just sharpened and became less sharp, but the length remained the same. However, it’s worth noting that it’s not necessary once in a while - I was just lucky with the purchase of high-quality screws. In general, although it is not advisable to drive on asphalt with such tires, it is possible if you do not maintain a high speed.

Using homemade winter studded bicycle tires. Advantages and disadvantages

I recently wrote about how to make studded tires for a bicycle. Some time has passed, I managed to ride it and now I’m ready to talk about the advantages and disadvantages of this bicycle tire.

First, about the advantages.

Although some people say that they drive normally in winter on regular tires, but, whatever one may say, the difference is obvious. Especially when braking. But it is the quality of braking that is most important when cycling in winter. Well, everything is clear with the advantages, let’s move on to the disadvantages and difficulties.

Flaws

Of course, such tires are a little more difficult to drive. But that's not the main thing. When driving on asphalt, the studs on the rear wheel wear off noticeably, so the rear wheel won’t last me for the whole winter (the front one is ok) and I’ll either have to make a new tire, or unscrew the worn-out screws and screw in new ones. But in this case, the tire rubber can wear out quickly, because A new batch of self-tapping screws will most likely not go along the existing thread, but will create a new one. But this is not the main thing. When I decided to stud a bicycle tire for the first time, one of the main reasons was the lack of winter bicycle tires on sale, or rather, they were very rare, and therefore there was no choice of options. But now they are on sale, and there is some choice, and you can probably buy any of them in online stores.

But looking at the arrangement of metal and rubber studs in bicycle tires, and understanding how and where there is a desire to ride in winter, my mood did not improve. It’s as if the employees of tire manufacturing companies who come up with products care about their products from too idealistic positions. Either asphalt and smooth ice, or compacted snow alternately with a snow-free road. And the studs are specially made so that they are more likely to get lost on hard surfaces, and you would have to buy another bicycle tire.

As a result of the reasoning - spend money on what is available or do what is much cheaper, but exactly as needed, I chose to do it.

Choosing a base - tires

First I decided on the parameters - what the tire should be. And taking into account the previous experience of studding old ones with a partially worn tread, I decided that only a new one and not a random one that can be obtained for free (or almost for free), but chosen from catalogs, or from those suitable ones that are on sale. As a last resort, I decided to wait for the one ordered from the online store, but the one that would be more suitable.

1. – should be folding, since it is much easier to remove and install in the cold than with a wire frame – tires with an aramid frame are softer and more manageable. Yes, and piercing with an awl, drilling, holding the direction of piercing and drilling, at the desired angle is easier, as is screwing in a tenon screw. If the tire can be turned flat. It is easy to press it with a clamp to the plane of a workbench or plywood (board).

2. – must be with Kevlar cord, since puncturing a tire in the cold and then gluing it is not an easy task due to that very frost. And I already had experience of a tire blowing out in winter - I drove over a broken section of a metal fence with a sticking out rod that was not visible under the snow. Then I sealed not only the tube, but also the tire - the gap was one and a half centimeters. The cold procedure took more than two hours. The fire had to be lit in order to glue at a positive temperature.

3. – The main point is the location of the rubber studs of the tire, because metal studs will have to be installed in them. So that the height should be no more than 4 mm - less than the branded winter ones by 1.0 - 1.5 mm, and the location and quantity would allow driving on hard surfaces with less losses. And so that when turning and passing inclined ice surfaces, the spikes end up in the place of the most advantageous application of forces - holding abilities. And it is imperative that the spikes be located more often along the contact path, for less mechanical losses when driving on ice.

4. – dimensions of the tire’s rubber studs. So that the size of the tenon, along or across, should not be less than 8 by 8 mm, since it will be impossible to hold the tenon under load - the rubber tenon will tear in the direction of the load on the metal tenon.

The tire we found and liked in all respects had 444 studs measuring 9 by 11 mm and 8 by 11 mm, 4 mm high, located in the best way for the planned winter rides on ice, asphalt and rocky dirt roads.

They turned out to be – KUJO DH 2.25 K, for installation on the rear wheel, and KUJO DH 2.35 K, for installation on the front, according to the condition of turning, and therefore at a greater angle than the rear wheel, to run into (slide over) ice obstacles.

Produced by – IRC.

They also had embossed inscriptions that were pleasing to the eye - MADE IN JAPAN, and sidewalls made of red rubber, softer in the cold, prettier than an all-black tire.

Basically, as if everything was about the tires, now we need to find what will then be metal studs.

Finding suitable tenon screws

It took a long trip to go shopping for fasteners, because what one offered could be worse than what could be found somewhere else. Only two sellers had visual stands to select screws, but for clarity, there were only one, two standard sizes, and not all that could be on sale. And I had to search the sites for links to articles by home-made people who were ahead of me in this idea.

In all the articles I read, self-tapping screws with sharp ends of screws or washers with curved pointed edges (homemade or furniture ones with a threaded recess - a washer-nut with horns) riveted with rivets or regular rivets were used. Both of them have one feature - to tear and tear everything that they touch or run over - clothes, wallpaper, linoleum, etc. Another reason for not using washers is that those for furniture need to be secured with a screw and a flat washer, but even with a thread locker they can be easily lost. But the main thing is that it is impossible not to get hurt when putting on or taking off such a tire, even with gloves or mittens made of strong, thick leather. An attribute that you will definitely need to take with you along with other tools if the spikes are so sharp. How to harden them is also a problem. And the losses when moving with such washers are large. In general, no washers.

In the end, the choice was made on self-tapping screws with a washer head, hardened, galvanized with a drill tip.

The drill ends of these screws do not scratch your hands and do not cling to fabric, fleece, or down jackets. They do not stick into linoleum or tear wooden surfaces under light load. But since the tips are made for drilling metal, they are more hardened (harder) than ordinary self-tapping screws. I tested it by trying to scratch the glass with self-tapping screws and sharp regular drills. With drills I was able to scratch with less pressure and right away.

The sizes were 7.5 mm, 9 mm, 13 mm, and 16 mm in length, and the diameters were 3.8 mm and 4.0 mm, which were quite suitable for installation in tires with different rubber thicknesses.

True, the 2 smallest sizes had caps with a diameter of 7.75 mm and without washer-like extensions. The rest have head-washers with a diameter of 10.7 mm. For some reason, sellers call them prewashers.

Since the studs were found and purchased, I could also buy the tires I liked, which were waiting for me at the Trial-Sport store.

Combining theory, guesses, other people’s and one’s experience into a single whole

First I had to think about the installation method - screwing in tenon screws, how to drill and pierce the tire so as not to damage the cord. Trying it on a cut piece from an old tire, cutting off the drilled piece at different angles and at different speeds, with drills of different diameters - from 1.0 mm to 4.0 mm, and changing the sharpening, I came to the conclusion. You need a drill with a diameter of 2.0 mm - 2.5 mm, sharpened at an angle of 45 degrees or more, with a zero or negative angle of the cutting edge, the attacking part of the drill. The best performance was when drilling with such a prepared drill, but in the opposite direction, as when unscrewing, the cord threads were not damaged at all. But even with right rotation, the results were not bad - the cord broke in isolated cases.

The technology is this: first pierce the tire with an awl where the spike will be installed. At an angle where the tenon is installed. Pierce from the outside so that the awl sticks out 15-20 mm inside the tire, so that you can see the location and angle - the direction of the hole. Take a drill with a drill and the direction of rotation switched to the opposite direction. The maximum revolutions are no more than 1000. It is more convenient if it is a cordless drill with speed control using a trigger. Note the location and direction of drilling, pull out the awl and immediately drill into the resulting hole. Put the drill and drill aside, take a second drill - an electric screwdriver with a Phillips screwdriver installed in the chuck - a pin that matches the number of the cross for the screw-drill. Place the screw-drill on the tip of a Phillips screwdriver (pin) and screw it into the hole at an angle of drilling - piercing with an awl. Check that the tenon screw drill comes out exactly in the right place, marked with an awl.

And do the same 443 more times, and then for the second tire the same amount - exactly 444 identical procedures - “Chinese labor”. A little “trick”, so as not to pierce the tire for each stud separately, was to puncture as many holes as the number of studs intended to be installed on a given day (work shift). Then he stuck parquet nails into the resulting holes, and took them out only before drilling, one at a time. Then he again inserted nails into the resulting holes, but thicker - 3 mm thick, immediately after drilling. And when he had drilled enough for the day, then he took out three-millimeter-thick nails one at a time before screwing in the tenon screw. So the holes did not “disappear” - they did not tighten, and it was faster and more accurate than repeating all the procedures with each spike.

First, a row of outer ones, at appropriate angles, pierced and inserted parquet nails (they are inserted easily) - you can immediately see whether the holes are straight and correctly marked by the protruding row of nails. Then the other extreme row, and then the rest along the rows. But not all around, but a section - a sector into which the tire was divided, like on working days. Observing accuracy and attention, each stage of work can be easily visually controlled using evenly placed nails.

The work listed above took approximately 30 working hours – two weeks in the evenings.

It could be faster, but I worked out the control technology, and it’s already beautiful - the result of the work is visible and predictable.

Attention - you need to pierce the tire with an awl once for one tenon, accurately marking the location of the hole according to the drawing, taking into account the angle along the red dotted line - 3-5 degrees from the black dotted line, no more.

The tire is 26 by 2.25 inches, stud screws of different sizes are used - the middle row is the smallest, blued, then - slightly larger galvanized, and on the outer rows the largest with a washer cap.

Close-up – tire 26 by 2.35 inches. It can be seen that the screws are screwed into the outer rows at an angle favorable for holding the ice. All the spines are the largest, with a pin-shaped cap.

I called a trial specialist I know and asked: “Are there any unnecessary thick rubber tubes left with the nipple torn off?” It turned out that there are as many as 3 pieces. It was from these chambers that I cut out the strips. I cut the sides in the middle and used the outer part. Two chambers with a wall thickness of 1.5 mm and one with a wall thickness of 3.5 mm are heavy, the whole chamber weighed 600 grams, like a tire.

Thick-walled chamber, cut off in the middle of the sides. For insertion into a rear studded tire – protects the bicycle tube from the heads of the studded screws. There is also more load in the middle rows of tenon screws; small-diameter caps are more prominent.

I installed a thick-walled strip under the rear tire, and a thinner one under the front. One thinner one is a spare one. Inflatable bicycle tubes, used by Schwalbe, at a price of 240 rubles - ordinary, but made of high quality rubber. I bought it at Leader-Sport, on the street. K. Marx.

Rear tire from the inside, visible inner tube with marks from the heads of the stud screws. There were no breakthroughs, there was no hint of abrasion - the “gaskets” can be thin.

Tests

This most exciting and interesting thing happened from the Tyomnaya Pad station and while crossing Lake Baikal on the ice.

At first, of course, I was driving to the central passenger station on the asphalt.

The first impression is the sound, like a dog running along linoleum or parquet with its claws extended, but stronger. We are driving with a friend whose wheels have no spikes. But since there is no ice, we drive quickly and seem to be stress-free, although we are careful not to slip and away from the cars.

The trials of skating on the skating rink were surprising, but only for a moment - normal skating, turns and braking without problems. But there were no cars with pedestrians at the skating rink.

So no unusual impressions appeared. I tried to brake sharply and turn around - it was fine. It seemed that without spikes my friend was less confident, but this did not seem to be some kind of indicator. We're going by train to Tyomnaya Pad. How will it be there?

We arrived, looked down at the path and... drove off. At first, slowly, and then somehow inexplicably confident and taking more and more risks. Braking with the rear wheel, helping and sometimes dragging one foot in the snow, like motocross athletes, and even accelerating and jumping in some areas. Creepy. Suicide slope.

I look around - my friend is gone, his bike is gone too. I had to dismount and search. It turns out that, braking with the rear wheel and finding that this had no effect on the steep slopes of the track, he began to slow down with the front wheel, but this did not help on the snowy path. He began to accelerate and ran into a piece of soil bare of snow. The front wheel, locked by the brake, and it had rim brakes, stopped them both and threw one, over the handlebars of the other, down the slope. But somehow silently - I didn’t have time to get scared and scream. Then the bike flew away too. One lies below, silently in the deep snow, and the other, rotating its wheels in an inexplicable position, ten meters to the side. The one without wheels responds with some phrase from an anecdote and unprintably about a close relative. The snowdrifts received both without defects - they flew next to huge stones and lying tree trunks.

Watching the action described above, for the first time I became proud of my bicycle studding. After all, I never slipped even once, although I was afraid a lot.

Further down, on the Angasolka River, there was a super test. I drive down the path to the bridge, and from it onto the lumpy ice - snow on top, a layer of wet slush underneath, and ice at a depth of 5-10 cm. I reached the tree, looked back, and my friend was walking around this ice disgrace along the slope with a bicycle on his shoulder. He screams that it’s impossible not only to drive, but even to walk – it’s slippery and wet. Once you fall, you will have to continue driving wet.

I let go of the tree and food, no sensations, normal driving, only splashes of sludge to the sides. I even liked it, I skated in different directions, because the ice on the river is lumpy and inclined, like a slope. Amazingly, no uncertainty, the ride is easy, like on dry and hard gravel. I didn’t want to go further, an absolutely unusual feeling from ordinary confident skating - you go easily, shift, accelerate, brake, but this is a very slippery and uneven place, more slippery than just ice. I haven’t walked through such places yet, but on the contrary, I avoided them.

While we were driving to Lake Baikal, out of interest, I chose the opportunity to drive on the ice of the river, where it is under slush, wet, bumpy, and whatever - the driving is absolutely normal, there is no stress, so as not to slip. It’s easy to slide onto the ice and drive back onto the shore where the trail runs.

On the shore of the lake, several skiers took skis and poles in their hands and went to the snow drift so that they could ski along it to Slyudyanka.

Looking at the absolutely flat and smooth ice, I was a little confused - how would it go? But having driven onto it, I heard the noise from the spikes and that’s it... no other feelings - just like on a flat road. I accelerate, I brake, I make such turns that I almost fell several times, I jumped and bucked as best I could and... NOTHING. It’s even strange, because you can ride on smooth asphalt in exactly the same way. I began to mock myself and my bike, but no amount of maneuvering or braking allowed me to slip or skid, either on the ice or on thin crust. True, I turned over the steering wheel several times, both straight and sideways. That day, only my friend had problems - he was driving no faster than 6-9 km/h, and then on low tires. At normally inflated speeds, even 3 km/h, the problem was falling and slipping every 5-10 meters. I can’t imagine how many bruises and bumps I brought home. True, I brought it too - from flying over the handlebars. One of the flights was caused by sharply braking with one rear wheel.

The main impression is one thing - NO IMPRESSIONS - ordinary skating without problems and uncertainty. Self-studded tires “hold” on ice or a dense snowy road much better than new tires on clean summer asphalt.

Another time, to the Angasolka River, I drove along the highway and gravel road for almost 20 km - I didn’t lag behind, even sometimes went ahead on the descents, although everyone with whom I rode in a small “gang”, except me, was riding on branded spikes.

We went down to Lake Baikal past the village of Angasolka along a frozen dirt road. I’m on the crooked and wet ice on the Angasolka River, and those on the signature spikes are on the trail. The owners of the “company” tried it, one even fell, and stopped taking risks - driving on wet ice, and on Lake Baikal they didn’t risk sharp maneuvers, but in a straight line they could race with the company guys on equal terms. True, at the “firm” they could afford to press the rear brake sharply and strongly - the rear wheel skidded slightly to the side, and I could fly over the steering wheel.

It’s a pity that I didn’t take a camera and there are no pictures of those tests. Twice I rode in company with Diagran (who knows) on his spikes, both on the highway and on the snow and ice of Lake Baikal - you can’t keep up with him even on highways on asphalt, he drives on ice at 35 km/h on ordinary branded spikes - a monster.

On the train, when setting up the bike, there was no fear that you could tear your clothes or fleece gloves on the homemade spikes, I took it on purpose.

By spring, it became noticeable how the drill bits of the tenon screws became dull and became semicircular, but this did not affect the holding power on ice and compacted snow. True, due to the fact that the spikes have become a little shorter, it seems to be easier to drive on asphalt and ice. And also - the more dull the drill bits become, the slower their abrasion occurs - the contact surface area increases. It becomes approximately equal to the area of hardened studs, like branded bicycle tires, without Pobedit inserts. In the first winter I rode about 700 km with studs, I don’t know more precisely, since the bicycle speedometer “died” after 600 km. On asphalt and concrete with ice, it turned out to be about 100 km, about another 250 km on gravel and dirt roads, the rest about 400 km on ice and dense snow.

I think that with my use, it will be enough to drive at least 1500 km before replacing some studs.

Theory confirmed by practice

The proposed stud installation angle was derived from the assumption that the greatest shear load on the stud is during braking. And in order for the spike to “bite” into the ice in the best way, it must be installed at a negative angle to the plane of the support when moving forward.

The side spikes are also at a negative angle to the plane of support from the corresponding side, as when driving on a slope or when turning at speed. And since, under shear load, the studs will deflect in the elastic rubber of the tire, this deflection will be smaller due to the greater thickness of the rubber behind the stud and the greater elasticity of the thicker layer of rubber.

I did not glue the gasket between the bicycle tube and the heads of the self-tapping tenon screws, since the gluing will not be tight, and water and dust will get into the leaks - dirt will be in it, and inserting and removing this gasket is not particularly difficult.

How will water get there?

Let’s say you had to drive in wet places, and then remove the tire and tube in a warm place - water from the internal volume of the rim will flow into the tire.

And you need a lot of glue - 2-3 full tubes per wheel. If the result is mediocre, the gluing quality is poor. After all, the raised caps will interfere with the ability of the rubber of the cut tube to stick to the inside of the tire. And with a thick layer of glue, “chewing” sounds will be made, which happened when I glued bicycle tubes to road bicycle wheels on an excessively thick layer of glue - poor quality gluing. And since high-quality gluing cannot be achieved, then why do it poorly? After all, if you have to replace any spike, you will still have to tear off the glue.

I hope that what happened in the end, and which gave me the opportunity to be convinced of the correctness of my guesses and the work I put in, will help those who are not afraid to spend work, accuracy and attention for the final result - riding a bicycle where it was impossible before, but with These tires are safe and pleasant.

Recently, to make the ride easier, I decided to pump up the tires more. Actually, I didn’t pump them up too much, just the way everyone usually pumps up their tires in the summer. I went on business, and on the way back my rear tire went flat. At home, I pulled out the tire and found two strange holes on the tube, despite the fact that the tube lining was intact. I didn't bother and just taped the camera. The next day I went on a night ride and on the way my front tire went flat. Thoughts began to creep into my head that this was the work of self-tapping screws, or rather, the heads of self-tapping screws that could damage the camera. I disassembled the wheel, pulled out the inner tube, and sure enough, the entire inner tube had noticeable marks from the heads of the screws, and the hole was located exactly along the edge of the mark. In short, it was clear that the cause of the damage to the camera was the screw head.

There are 3 or 4 such damages on the camera. Moreover, this is not a hole, i.e. The chamber does not allow air to pass through. But, of course, you don’t want to travel with such a camera, because the crack can open at any moment. Let me remind you that I used an old camera as a gasket. As you can see, it is clearly not enough.

On a note

After inspecting both wheels, it turned out that only the camera on the front wheel was damaged. The rear wheel camera is fine. This is most likely due to the fact that the length of the screws on the front wheel is 2 times longer than on the rear. This is logical: when braking, 2-3 central screws bite into the asphalt/ice and, if they protrude strongly, they dig into the camera with the edge of the cap. Almost the same thing happens when hitting curbs. From this we can conclude that it is not advisable to leave the screws protruding more than 1.5 mm. In addition, if there are a lot of screws in the central row, then when braking a larger number of screws will work, which means there will be less impact on the camera.

What to do?

It became clear that the spacer camera alone was not enough. Also, adhesive tape will not be enough. In several places on the Internet I saw that people used a piece of linoleum as a gasket. I didn’t have any extra linoleum, but I remembered about the old semi-slick tire collecting dust on the balcony. I cut off its sides and inserted it into the front tire. I had to cut it down a bit to make it fit. If you do the same, cut the tire very carefully, because... if you cut off the excess, there will be a gap between the ends of the tire spacer, which will damage the tire. To avoid this, I sealed the joint with a piece of rubber from a bicycle first aid kit.

The wheel has become noticeably heavier and this is bad. On the other hand, if everything is done correctly, I will be almost completely protected from punctures and will be able to heavily inflate the tires to make the ride easier. Some may say that in winter you need to drive at low pressure, but when there are studs, increase the area work surface there's just no need.

Because I had one extra tube spacer left, so I decided to add it to the rear wheel. A gasket of two chambers should be enough.

Honestly, I don’t know what will come of this and how much more difficult it will be to drive. I decided on a desperate act: to make a lining between the tube and the tire from... a tire. It sounds scary, but in reality, everything is so =) She was found on the balcony old tire semi-slick, the sides were cut off. The tire itself was also cut and shortened a little, because It simply did not fit inside the working tire. I sealed the resulting joint with a piece of rubber so that the corners of the tire would not damage the tube. The resulting gasket was installed on the front wheel. On the back, I used as many as three (how many were old, I put in that many) cameras as a spacer.

Naturally, the bike became noticeably heavier after such abuse. To be honest, I assumed that I would not be able to maintain even 20 km/h all the time. However, I drove normally for about 35 km.

After driving about 100 km on these wheels, I disassembled the rear wheel to see how the tube felt. On the rear wheel, let me remind you, 3 old tubes act as spacers. Upon detailed inspection, no damage, tears or scratches were found. On the camera there were only soft, not sharp prints from the heads of the screws and nothing more. As I thought, this turned out to be an impenetrable option. The wheels, although noticeably heavier, are still quite possible to drive.

Separately, I would like to say about the wear of screws. The fact that the rear wheel will not be enough for the whole winter is for sure. The central screws on it were very worn out.

Basically, what else can you expect in such a snowless winter? If there was snow, everything would be fine. But I think when the screws protrude only 0.2-0.3 mm, the erasing process will slow down. When they wear off completely, I plan to unscrew them and screw in new ones. I'm thinking of screwing in more, because... The more self-tapping screws (and they don’t weigh much), the less wear they will have. On the front wheel, the screws stuck out 2-2.5mm and still do. Even the central ones have not worn off. This is very good, considering that it is the front wheel that is responsible for control on the road.