To give the doors a finishing touch, special strips are installed. Let's look at how to choose the dimensions of the extensions for interior doors and correctly install all the elements.

What is a door accessory?

Extensions are specialized planks that differ in parameters and textures. They are attached to openings and cover slopes.

They are placed in several situations:

- If the width of the box does not correspond to the thickness of the wall (masking irregularities, sealing slopes);

- To strengthen the mounted canvas and eliminate distortions.

Accessories for interior doors are important detail, so they must be selected according to the style, shade and structure of the panel (looks like a frame). They are bought as a set to avoid mistakes. The panels can be mounted in already installed or new doors on one or both sides of the opening (according to the location of the frame).

Mounted extensions look prestigious and, based on general style, make the interior solid, luxurious or discreet. They are fixed quickly and easily, which saves time and money. When finishing door block does not come into contact with wet compounds, does not get wet and does not deteriorate. This prolongs the life of the structure. Compared to standard slopes, the additional board becomes an extension of the missing width of the box.

What types of extras are there?

Everyone chooses their own technique for installing planks; you can do this yourself or turn to professionals. A flat, tongue-and-groove or edged board is suitable for the manufacture of elements.

If the walls are thicker or the installation is carried out in a damp room, then waterproof plywood, which resists various deformations (delamination, cracks), is considered suitable. Extensions made in production look more aesthetically pleasing and economical. The main material is MDF panel covered with a decorative layer. In addition to the fact that the finished boards have different dimensions (length 80-550 mm), they differ in the type of material and cost.

Based on the type of construction, there are the following options additional:

- telescopic;

- standard without edge;

- standard with edge;

- combined.

Rice. 2. Types of extras

Standard elements are simple laminate or MDF slats, covered with veneer, other coating or without it. Based on the quality of the end processing, they may have an edge. Some experts believe that there is no need to glue the facing edge to the edges, since one end is in close contact with the door frame, and the other is covered by the platband. In such a situation, it will be necessary to carry out the installation carefully, since even with a slight deviation the raw edge will become noticeable.

If you cover the end of the plank in advance with an edging tape of the appropriate shade, then minor imperfections will not be noticeable. The cost of the edge is low, and it can be glued quickly with a simple iron. Edging the ends will be preferable, as it prevents swelling of the material from moisture.

More complex design has a telescopic (stackable) element that can be attached to another thanks to a special ridge and groove on the edge. With its help you can line an opening of any width. The principle of its manufacture is identical to lining. Telescopic extensions differ in shade, thickness and type of material. The bar is placed in a groove where it can be adjusted, wedging deeper or plunging to a shallow depth. Installation does not require the use of fasteners. Typically, telescopic products correspond to the material of the panel, therefore they are made of plastic or wood.

The combined plank has an angular shape, since it simultaneously plays the role of a platband and an extension. For the production of planks, MDF, fiberboard, and waterproof plywood are used, which are veneered or covered with decorative film.

Do I need an extension for the door frame?

In any room, doors and frames differ in parameters and characteristics. For example, in the bathroom their dimensions are narrower than those of the interior rooms; they are more spacious entrance doors. That's why there are standards and size ranges.

When measuring the width of the box, it is necessary to determine the indicators of the opening and panel, since all characteristics are interrelated.

Rice. 3. Scheme and composition of the strip

Regardless of the convenience and aesthetics of the extensions, they do not always need to be installed. Their installation is carried out only in a situation where the width of the box is less than the wall opening for framing.

How to choose the right type and size

You can make the planks yourself or buy them from finished form. On construction market additions from standard parameters(0.7-2.5 cm wide, 0.6-3 cm thick and 2.1 m long).

To determine the required panel width, add the size of the slope to the depth of the box groove. With very thick walls, the plank can be 40 cm thick, but it will need to be ordered individually (its parameters should not exceed the dimensions of the groove in the box).

To make the slats yourself, you should take wood, MDF, chipboard or plastic.

When using natural wood, it is coated with antiseptic compounds to protect it from rotting and prolong its service life. Homemade MDF products will differ from purchased ones, since in the latter the cavity between the boards is filled with cellular material. Chipboards worse than MDF or wood panels in terms of operation and aesthetics, but they can be used indoors.

Planks are less often made of plastic, but if this happens, then metal-reinforced PVC panels are used.

Rice. 3. Variety of planks

Rice. 3. Variety of planks Installation of additional panels

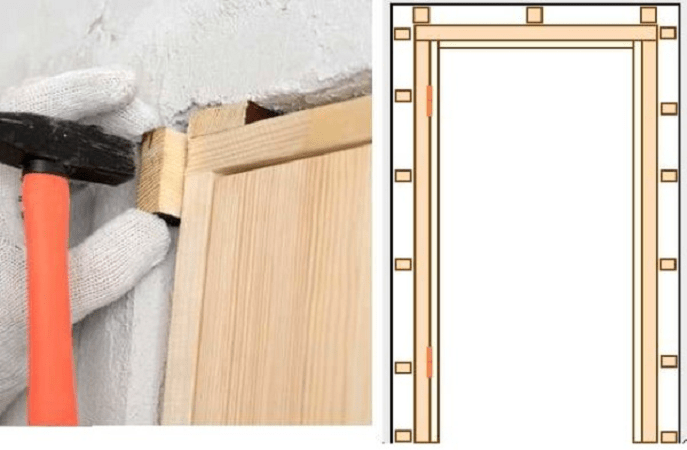

The following tools are used to fasten the panels into the opening: level, plane, tape measure, jigsaw, hammer and sharp knife. The building materials you will need are foam, fasteners and planks. To install the products correctly, you must follow the instructions.

Installation of any types of extensions on interior doors can be done in several ways:

- Slot mounting. If you plan to use planks, then it is desirable that the box has a special groove. This will speed up the installation process and allow you to slightly extend (or push) the bar inward, increasing accuracy.

Rice. 4 Taking measurements and installing the strip

Rice. 4 Taking measurements and installing the strip The box must be fixed in the opening, so before placing it, measure the distance from it to the edge of the wall. The size of each slope is made separately at at least 4 points using a construction square. Usually these indicators differ. The width of the slope is added to the depth of the groove in the box, resulting in the parameters of the plank. You can trim the extension with a saw or jigsaw to the optimal size.

When using telescopic products, platbands and a box of the same type are selected. The assembly of the block is carried out like a construction set, by inserting protrusions into the recesses of the parts. Glue provides additional strength to the panels and trim.

- Installation without groove. If there is no groove in the box, then the elements are attached tightly. Such an installation requires precise measurements, detailed adjustment of elements and accuracy.

Rice. 5. Fastening with self-tapping screws

Rice. 5. Fastening with self-tapping screws The size of the slopes is determined similarly to the first installation method, the parts are trimmed, and an edge is glued to the cuts. Nails are driven into the end parts at intervals of 20-25 cm and their heads are bitten off with pliers. Then the side planks are placed, after which the top one is at a right angle and nailed with a hammer.

- Fastening with self-tapping screws. The width of the extension is determined, which is screwed to the wall, the side parts are adjusted to size. Holes are made for self-tapping screws and screwed to the wall. After sealing the joints, the casing is attached, and furniture plugs are installed to mask the screws.

Eliminating gaps after installation

Rice. 6. Closing gaps

Rice. 6. Closing gaps The immobility of the extensions can be ensured by fixing them with masking tape to the frame and walls. Spacers are placed between the two elements, and if they are missing, the gap is filled with foam. You should take a balloon and introduce foam in small portions (so that the structure does not move). After it dries, the excess is cut off with a knife at the level of the wall.

Door extensions allow you to aesthetically design the opening. With minimal skills in handling glue, nails, saws and foam, such work can be done independently.

When installing door frames, it often becomes necessary to cover the remaining part of the slope with something. Most often, “extras” are used for these purposes, which can be purchased along with door leaves and trim. However, in most cases, such additional elements require adjustment, since the additional elements should be attached to the box as tightly as possible, and always strictly according to the size of the visible part of the slope.

Door frames

There are two options for door frames to which extensions are usually attached:

- with a groove for it,

- without groove.

In the first case, the additional element is inserted into the groove of the box with one (long) side, while its second side is unattached.

In the second option, the extension will need to be attached to the slope, without fixing it to door frame.

Choice of extras

Extensions are strips made of laminated MDF. The color of these elements usually matches the color of the door frame and trim. But if you wish, you can always purchase additional colors of other colors, if this option is more suitable for the design of your room.

Do not forget that the extensions cover the slopes on three sides - on top and on two sides. In this case, it is desirable that the top addition be longer than width doors, and the vertical extensions rested against it at right angles.

The varied width of the extensions allows you to choose them for slopes of almost any width. The main thing is that the additional element does not turn out to be narrower than necessary. If you cannot choose the exact size of the extension, you can trim it. To do this, it is recommended to contact furniture workshops, since you should additionally order a sticker there edge tape on one or two ends of the extension.

Installation of extensions with a groove

First, let's look at how to attach the extensions to the door if the door frame has a special groove:

- Install and secure the door frame in the opening. You can even hang the door - this will not affect the installation of the extensions.

- Trim the extensions to the required length.

- Measure the distance from the outer edge of the wall (slope side) to the door frame in at least three places. If these distances do not coincide, then the extension will have to be cut in a furniture workshop. On the end of the extension to which the casing will be attached, it is also necessary to stick the edge tape there.

- Insert the extensions into the grooves of the door frame: first the top horizontal, then the side vertical ones. The extensions must be located strictly at an angle of 90 degrees to the plane of the door frame.

- Check that they are horizontal and vertical.

- Paste masking tape in 4-5 places along the length of the extension in such a way as to use it to fix it in the desired position.

- Fill the space between the wall and the extension with polyurethane foam.

- Wait until the foam hardens, cut off any excess.

- Attach the trim.

Installation of extensions without a groove

After installing the door in the doorway, it is necessary to measure the remaining uncovered part of the wall (slopes). If the extensions have to be cut lengthwise long side, then it is better to do this also in a furniture workshop. There you can also order the edging tape sticker on the two ends of the extensions (both on the side adjacent to the door frame and on the side of the platbands).

If the slopes are not plastered, then the extension should be secured as follows: take a wooden plank or small beam and attach it to the slopes in such a way that the extension can be secured on top of this plank, while maintaining its verticality (horizontal for the upper extension) and a right angle between it and the door frame.

With smooth plastered slopes, you can do without an additional wooden plank, provided that there is no need to leave any space between the extension and the wall.

- Attach the extension to the bar.

- Fill the remaining space between the wall and the extension with polyurethane foam. To make the foam harden faster, spray it with water.

- Trim off any excess hardened foam.

- Secure the trims.

Benefits of using extras

As you can see, the technology of fixing the extensions allows you to avoid such a tedious procedure as plastering the slopes. A correctly selected additional element makes the slope smooth and beautiful, no matter how bad the slope looked before. However, if the space between the extension and the wall exceeds 3-4 centimeters, it is better to additionally secure the extension using small wooden blocks screwed to the wall.

In cases where you do not have the opportunity to use factory-made additions, you can make their man-made “analog” from laminate or MDF panels. This solution will make it possible to create “diverging” slopes (not located at an angle of 90 degrees relative to the door frame).

Video

Useful instructions for installing extensions:

Below you can see how the extensions are installed:

The ability to handle carpentry and measuring tools is already a reason to try to solve such a difficult task as installing interior doors with your own hands. The work is simple, but tricky in its own way. It will take scrupulousness and even tediousness in marking and adjusting, otherwise it will not be possible to install the interior door with the frame correctly.

Features of installing interior doors

At first glance, nothing complicated, but this is only a superficial impression. It's about about not just installing the box and door leaf into the interior opening, and do it beautifully, without distortions, scratches or sagging hinges. If this is your first experience, then it is best to make detailed step-by-step instructions for installing interior doors yourself before starting work. This is not shameful for beginners. Even experienced craftsmen often make notes with their own hands - what not to forget and what to pay attention to when installing a door frame on a specific interior partition.

During the installation process, you will need to solve two of the most difficult problems yourself:

- Correctly assemble and install the frame of interior doors, align and secure it so that the frame does not sag under the weight of the door leaf;

- With your own hands, mark and cut out mounting grooves on the vertical post of the box and on the end of the canvas interior door.

It takes an experienced craftsman 2-3 hours to install an interior door; a beginner will need at least a day to completely install the frame and hang the door leaf.

Advice! It is not necessary to stupidly follow the instructions for installing interior doors, which recommend sequentially installing lock fittings, attaching hinges, and only at the very end solving problems with hanging interior doors. The main thing is to install the frame and door leaf with your own hands with a fresh mind, and you can put off the trim, locks and handles with trim for the next day.

There will be a lot of measuring and sawing. All cuts are made by hand hand hacksaw, therefore, in addition to fresh forces, you will need to stock up on quality tools.

Tools for installing interior doors

A day or two before the start of work, you will need to assemble a working arsenal for working with lumber. You can collect it from friends or rent it. Why two days before installation? Because well before starting work, you will need to check with your own hands the serviceability and functionality of each tool:

- Construction levels - small, 70-100 cm, and large, 150 - 200 cm, with a working bubble indicator. Usually they don’t pay attention to the condition of the camera and beacon, considering them to be in good working order, but at rental stores you can sometimes find bent and even broken copies, these are the most important tool in the installation of interior doors;

- Marking tool - carpenter's corner with a ruler, tape measure and meter metal ruler. We check for the presence of angle marks at 90° and 45°;

- A screwdriver or electric drill with a bit attachment for cross-head screws. We check with our own hands how the cartridge holds, and the serviceability of the wiring - batteries;

- Cutting tool, you can cut the timber of interior doors with a jigsaw, but it is best to stock up on a pair of hacksaws - carpentry and metal. The first is used for cutting box parts, the second is used for fine cutting of platbands.

In addition to the tool, you will need a hammer, a clamp, a carpenter's chisel, foam in a can, tape and gloves. There is little dust and waste generated when installing interior doors, but you will still have to periodically remove it with your own hands so as not to spread it throughout the apartment.

In addition, it would be correct to have a hammer drill with a bayonet blade in stock, because when installing an interior door frame, problems may occur with the doorway in the wall. Ideally, the gap between the frame posts and the ends of the opening should remain 10-20 mm, for normal alignment and foaming of the cracks. In reality, the opening may be uneven, and you will need to knock down part of the concrete or stone with your own hands, a hammer drill or a hammer and chisel.

How to assemble an interior door frame

The best option would be to purchase a ready-made door kit, which usually includes:

In this case, the entire process of installing the box interior frame comes down to transferring the second parts of the hinges onto the frame parts with your own hands, assembling the holes with self-tapping screws and installing them in the opening.

The entire job will take less than two hours. One of the options for installing interior doors with your own hands in the video

The only drawback of the above scheme is that not all manufacturers modern models interior doors manufacture their products in kits designed for do-it-yourself installation. Most often, the customer buys a door leaf, and the trim and frame parts are purchased with the expectation of installing an interior door with a frame on their own.

How to install an interior door with your own hands

First of all, you need to lay out the door leaf on a level area. Next, the selected pair of beams is laid to the left and right ends of the sash. Using a tape measure, we measure the width and expected height of the future supporting frame. Then, using a building level and a tape measure, check the dimensions of the interior passage.

Important! This is done in order to determine whether the platbands will cover the edges of the hole in the wall, and what thickness of additional elements should be used.

If you “miss” the height or width of the frame, you will have to redo the trim yourself or, even worse, you will need to raise the interior door in height.

Assembling a door frame frame of any size

In order to install the interior door without distortions, it is important to choose the correct distance between the left and right posts so that the door leaf fits into the frame with a small gap, no more than 2 mm on each side. In this case, the door will open freely without jamming in the hatch.

The easiest way to assemble the frame with your own hands is using a clamp, a saw and two blanks. Vertical posts, as in the case of preparation, are placed at the ends, leveled and secured with clamps.

On the side of the upper and lower edges of the canvas, an allowance equal to the thickness of the timber is left on the workpieces. At the same time, on the left allowance, a cut line is applied with your own hands at an angle of 45° for further joining with the horizontal crossbars of the frame. Without disassembling the structure, markings are applied to cut out the grooves for the canopies, lock and handle.

If the interior door is too wide or complex shape, then usually at this stage they check the conformity of the configuration of the frame with the door to the shape of the interior opening. To do this, a pair of nails are driven into a wooden plank at a distance from each other equal to the outer width of the frame. The plank must be secured above the opening, and a couple of plumb lines are hung on the nails. If the gap between the frame and the wall is 10-15 mm, then the calculation is correct.

Installing hinges on an interior door

After all checks have been completed, it is necessary to cut out mounting grooves for the awnings in the canvas using a chisel or carpenter's knife and hammer. The easiest way is to mill a niche using hand router, but, as practice shows, the work can be done with your own hands and without expensive power tools.

If this operation is difficult, then for interior doors you can use overhead hinges or models for drilling. For installation you only need to drill holes for screwing in the fasteners.

We fix the frame in the doorway

- We mark the level of the upper horizontal cross member of the frame with a marker on the steppe, this will help to perform the correct installation horizontally and vertically;

- Using wedges and a building level, we level the frame vertically and horizontally with our own hands. We fix the position of the frame in the opening wooden plugs and wedges.

Advice! If the frame and door leaf are light in weight, then the frame can be fixed with mounting perforated petals to the wall of the interior partition.

Next, you need to blow out the space between the frame and the wall with polyurethane foam; while installation is being carried out on the polyurethane foam, you need to check it again and, if necessary, finally level it vertically using a long building level. Apply a small amount to the top mark building level and, if necessary, we adjust the frame to the required height.

Installation of door leaf

After the loot is firmly fixed with hardened foam, it is necessary to install the mating parts of the canopies. To do this, initially the door leaf is raised with wedges so that there is a gap of 1-2 mm between the threshold and the lower edge.

All that remains is to install the sash on the awnings, and you can move on to decorative finishing interior doors.

Installing trim on interior doors

Covering the frame with platbands is not particularly difficult. First of all, install the vertical trim strips. The height of the plank is measured according to the mark made earlier, after which the platband is applied to the frame and the cut line is marked at an angle of 45 degrees.

Advice! It is best to make the cut yourself using a thin hacksaw blade for metal. First stick tape onto the cutting line. The plank is nailed with wallpaper nails or placed on glue.

The second vertical casing is installed in a similar way. After the installation of the vertical parts has been completed, you can mark the cut line on the horizontal strip and install it on the door frame in the same way.

What are the sizes of extensions for interior doors?

Additional strips are used as additional element to increase width or thickness door frame. Most often, installing extensions on interior doors is required in a situation where the wall is much thicker than the canvas, and there is a gap between them that needs to be closed.

The width of additional slats ranges from 10 mm to 200 mm, for interior designs the most popular size is 10-20 mm, and often, due to the non-standard profile of the slot, the extensions have to be ordered or cut out with your own hands from the trim strips.

How to install extensions on an interior door

If after installing the box the unpleasant fact is discovered that vertical plane frame is recessed into the space of the interior opening relative to the wall surface, then the only way to correct the position is to use additional strips.

You must first determine the size of the extension; to do this, place a building level on the wall and use a ruler to measure the distance to the front edge of the box. Thin strips are nailed with wallpaper nails, wide extensions are glued to the frame.

Professional advice on how to install interior doors

Among the features of installing home doors are the following: problem areas.

Before installing the trim, you need to make sure that the frame or additional strip is located in the same plane with the surface interior wall. Otherwise, even if you do it perfectly with your own hands, a gap will definitely appear between the platbands.

The second problem we have to face is sagging doors if installed incorrectly. To correct the position, you need to remove the door leaf, place washers, or trim the edge and install the door in place.

Conclusion

Installing interior doors with your own hands will require a little practice in installing awnings and extensions, but in general the work is not difficult, and with the right skill you can hang the door in a few hours. The craftsmen claim that with each installation, the quality of their DIY work doubles.

Why are extras needed and what are they? Before answering this question, we need to remember a little, and young people need to study history. As it was before? Each production plant building materials strictly complied with the current state standards for its products. The sizes of bricks, blocks, panel slabs, etc. were regulated. d. Construction organizations had standards for the thickness of plaster. This allowed woodworking enterprises to produce woodwork (windows and doors) with standard door frame sizes. After installing them in the openings, no additional adjustment with additional trims for the platbands was required.

Today everything is different. The vast majority of enterprises are not guided by state standards, and their own technical specifications. This has led to the fact that the same brick or block from different manufacturers can have various sizes. Now no one can confidently determine the thickness of the walls, make several standard sizes door and window frames are not possible. The solution was found simple and effective. The box is made with the minimum permissible width, which guarantees its physical strength, and the missing width, depending on the thickness of the walls, is gained by installing extensions.

Due to the fact that most modern door frames are made of MDF in order to reduce costs, the same material is also used during the manufacture of extensions. There are, however, door frames and trims made of natural wood, but they are rare and cost much more. Principles for installing wooden and MDF dobor are no different.

Extensions are ordinary boards made of MDF, have a width from 100 mm to 200 mm, are produced by door manufacturers, and have the same color and texture as the doors. According to their design, they can be ordinary (simple) and adjustable. Simple extensions rest against an L-shaped cutout in the sides of the box; adjustable ones with the box have a tongue/groove connection. This allows you to accurately adjust the protrusion after taking the preliminary dimensions and preparing the extensions. In addition, the presence of the connection somewhat simplifies and speeds up the foaming process.

| Photo | Size | Color | Price |

|---|---|---|---|

| 8x100x2070 mm | bleached oak | 114.00 RUB/pcs. | |

| 10x100x2070 mm | Italian walnut | 167.00 RUB/pcs. | |

| 12x2150x2150 mm | snow rosewood | 188.00 RUB/pcs. | |

| 12x80x2100 mm | pine | 193.00 RUB/pcs. | |

| - | acacia | RUB 2,192.00/piece | |

| 100x2150 mm | nut | RUB 468.00/piece |

We will look at installation methods for both types of extensions, starting with simple ones.

Prices for extras

Installation of simple extensions

Simple additions can be connected with foam (the most quick way), nails and screws (the longest method). Choose yourself the method that seems most appropriate to you; experienced builders install extensions only on foam. The method of installing the extensions has almost no effect on the reliability of fastening the platbands, and the work is significantly simplified and accelerated.

Adjustable extensions are installed only on foam.

Measuring and preparing accessories

The technological task of the extensions is to serve as a platform for attaching platbands. In order for the platbands to lie correctly, the end of the extensions must lie in line with the plane of the wall. Measurements should be taken on an already installed door frame. Sizing is performed in the following ways.

Now you need to find out the height of the left and right elements and the length of the horizontal one. At the top of the box, the extensions are connected by the letter P, take this into account when taking dimensions.

You can cut additional boards hand saw, jigsaw, portable electric saw or at stationary machine. The latter option is preferable - the work is much faster, its accuracy increases and the risks of chipping are minimized.

First, cut the pieces to length, then make width marks on each one at the ends. Draw a straight, even line and carefully cut off the excess part. It is better to draw a straight line using the same extensions; you don’t have to look for straight and long wooden slats. At the cut site, you need to remove a small chamfer, so the board will fit more tightly to the door frame.

Jigsaw prices

jigsaw

Video - Measuring extras

All elements are prepared, you can start installing them. Let's start with the most complex method and end with the simplest.

Installing extensions with self-tapping screws

Step 1. On the extensions, make a hole for the screws.

The thickness of the MDF boards is 10 millimeters; for melting you need to take a drill with a diameter of no more than 9 millimeters. The exact diameter should be coordinated with the diameter of the screw head. The diameter of the caps, in turn, changes with their length. The length of the screws is selected so that they fit into the door frame two or three turns, otherwise it may crack.

It is advisable that the drills be made to look like wood; they have thin needle-like protrusions at the end, which allow more accurate centering of the hole and prevent the drill from moving during drilling.

Important. Always leave at least 1.5 mm of board thickness on the side of the front part of the extension; there is nothing to worry about if the hole for the countersunk completely drills out the side of the extension with reverse side. The depth of the hole is regulated by the length of the screws; the main condition, as we have already mentioned, is that they should be screwed into the box no more than two or three turns. In total, it is enough to install 4 screws for the long vertical part, and make the same number of holes.

Step 2. Drill holes for screws. The diameter of the drill must correspond to the diameter of the screws. Drilling these holes is somewhat more difficult; you need a keen eye and dexterity.

How to drill them?

- It is better to drill holes on the back side of the holes for the countersunk.

Very important. You will need to drill not perpendicular to the plane of the board, but at a slight angle. This is done so that the self-tapping screw is directed towards the center of the door frame - they are reduced possible risks its cracking on the front part. If the end of the screw comes out from the back of the box, there is nothing to worry about.

- Place the drill perpendicular to the drilling plane exactly opposite the hole for the countersunk.

- Drill a few millimeters deep, turn off the drill. Place the drill under the right angle and continue drilling until its end appears in the hole for the countersunk.

We have already mentioned that this method is the most difficult, and we do not recommend using it. But, if someone has convinced you, then we will continue to talk about him. Prepare all the elements of the accessories using the described method.

Step 3. Insert the screws into the holes and twist them until the ends appear on the opposite side.

Step 4. Screw on the vertical extensions first, then the horizontal ones. If the self-tapping screw is tightly screwed, do not use much force, unscrew it a few turns, and then screw it in again.

Step 5. Check the position of the extensions; if there are places with a loose fit to the door frame, press them with any available materials.

Step 6. Prevent the boards from bending with polyurethane foam.

To do this, you can fix them in two ways: with construction paper tape or spacers. Construction tape has high tensile strength in the perpendicular direction and calmly holds the force of the foam. If the wall is smooth, use carpenter's tape and stick it to the paneling and the wall in three or four places. vertical elements and two or three on the horizontal.

If the tape does not stick to the wall, use spacers. They can be made from wooden slats. The length of the slats should be 1÷2 centimeters shorter than the width of the doors. Subsequently, the spacers are pressed with various pads.

Step 7 Fill the gap between the wall and the extensions with polyurethane foam.

Very important. It is rare to find responsible builders who, before foaming any structures, clean them of dust and wet the surfaces. And foam has very weak adhesion to dry surfaces; there is nothing to say about dust and dirt. Try to touch fresh foam with a wet finger - then you won’t be able to wash it off with anything.

For foaming, use any foam, the extensions are not a door frame, they do not carry any load, you can use the cheapest brands. The main thing is don’t leave any gaps. If the gap between the wall and the extension is narrow and deep, fit various extensions to the nozzle. For very thin cracks, we used cocktail tubes - we taped them to the existing outlet of the foam can and worked. This design, however, is disposable, but you don’t need more.

Step 8 Wait at least 24 hours for the foam to cool, sharp assembly knife cut off any excess that appears. Check the stability of the position of the extensions by tapping. If you find problem areas, add foam to them.

Prices for polyurethane foam

polyurethane foam

Video - Installing extensions with screws

That's it, the work on installing the extensions is finished, you can start working with

Installation of extensions on studs

In this section we will talk about another way to measure the dimensions of the extensions. They need to be inserted one by one into the seats of the door frame and using the sharp side of the rule to draw a wall line.

You must act carefully. If you inserted additional elements in the position in which they will be fixed, then the marked line must be symmetrically moved to the other side of the board and only cut along it. But you can insert the board rotated, then the line will immediately be in its place. Further, all circumcision operations are identical to those described above.

Step 1. Using a small diameter drill (should correspond to the diameter of the finishing nails no more than one millimeter), drill holes at a distance of approximately 20 cm in the end of the extension adjacent to the door frame.

In the photo - the finishing nail next to the finisher

Important. Drill carefully and keep the drill strictly vertical. The depth of the holes should be 3–5 millimeters less than the length of the nails.

Step 2. Insert the nails into the drilled holes until they stop. Before this, you need to bite off the caps with pliers; the carnations are inserted with the sharp end outward.

Step 3. Carefully insert each accessory element one by one into its place in the door frame. Hammer through wooden spacer drive the sharp protruding ends of the nails into the door frame. Take your time; before fixing, firmly press the additional element against the side of the protruding seat of the box. If you are inattentive and miss a gap, you will have to remove the additional element and start all over again or seal the gap with sealant that matches the door. Both options are highly undesirable. In the first case, because you will have to pull out the “wrong” nail and drill a hole for it in another place. The fact is that the incorrect fastening is located a few tenths of a millimeter from the correct one. And in this case, the nail will never make a new hole for itself, but will always slide into the existing one. In the second case, any sealing of cracks with sealant will not go unnoticed and will indicate the low professionalism of the performer.

Step 4. Wedge the extensions on the back side, secure their position with tape or spacers to prevent them from bursting with foam.

Step 5. Clean the surfaces from dust and dirt, moisten them with an ordinary water spray (spray).

Step 6. Fill the gap with sealant over the entire surface. After the foam has cooled, carefully cut off the protruding part.

Video - Installing extensions on studs

We deliberately left the simplest method for last, this will give you the opportunity to compare all the described methods and make right choice. Marking and cutting out elements is no different from the first two.

And then everything is simple. Put the extensions in place, wedge them with inside until the surfaces are completely pressed against seats prevent the door frame from bursting with tape or spacers and foam it after cleaning and wetting the surfaces. As you can see, there are no steps, drilling or hammering. Why do we recommend using this particular method?

- The strength of such an installation is no different from complex methods.

- You never run the risk of damaging the extensions while drilling holes or driving in nails for one simple reason - there are no holes or nails.

- While the “big” specialist is drilling holes for screws or nails, you will completely install the extensions on two door frames yourself with the same quality of work as him.

Compare how much less technological operations, how much less are the risks of damage to the extensions and door frame and how many more are the benefits? Now make your decision.

Video - Installing foam extensions

Installation of adjustable extensions

Adjustable extensions have several advantages.

- Connecting the elements into a tongue/groove allows the elements to be tightly pressed with visible planes. The appearance of cracks is completely eliminated; there is no need to wedge them.

- The extensions can move up/down or out/in in the door frame. These few “free” millimeters allow you to precisely adjust their location and compensate possible mistakes during measuring or sawing.

Such extensions also have a drawback - they cannot be installed without a stationary circular. The fact is that only a stationary circular saw can be used to cut a tenon on additional elements required thickness and depth.

How are they installed?

Step 1. Take measurements, while taking into account the depth of the groove on the door frame. You can measure it and add it to the resulting width values, or you can take a piece thin plywood or a ruler, insert it into the groove and in this position measure the width of the extensions. Take measurements in several places around the entire perimeter of the doorway; walls are often uneven.

Step 2. Mark the left and right extensions and transfer the dimensions to the blanks.

Important. In order to simplify the installation of all elements in the future, reduce their width by 2–3 millimeters. This reserve will make it possible to move the extensions in the grooves in the desired direction.

Step 3. Cut the blanks to length and width.

Step 4. Set the stop circular saw to the width of the tenon, raise the saw table in such a way as to ensure required height thorn. Place the board on the edge and carefully cut out the tenon.

Step 5. In the same way, prepare all the remaining elements of the additions.

Everything else is simple. Install them in place, align them at the joints and along the plane of the wall. To prevent expansion, stick construction tape to the wall and extensions, clean the surfaces from dirt and dust, wet them and foam them. The presence of a tongue/groove connection eliminates the need for wedging; the extensions already hold their size perfectly and are tightly pressed to the door frame.

Video - Installation of adjustable extensions

When installing accessories, do not create unnecessary problems and difficulties for yourself, use only the third most in a simple way– installation on foam. Why?

- Firstly, the extensions are never affected by pulling forces; in any case, they will reliably hold the platbands.

- Secondly, the nails serve only to securely press the extensions to the door frame, and do not keep them from being pulled out. Ordinary wedges made of foam plastic, paper and other available materials cope with the same task no worse.

- Thirdly, any “drilling” in thin boards and in the door frame can cause cracks to appear on the front side. You will have to change the accessory or repair the box.

No one needs the first, second, and third. Why are there the first two installation methods? We think this is one of the effective methods undeserved increase in wages for unscrupulous builders. They importantly tell customers that for such complex work they need to pay appropriate amounts.

You should not nail the horizontal expansion to the vertical ones in the corners of the joints; it is already perfectly pressed with foam. If you are worried, press it in these places with any wedges. Extra nails in thin trims are an extra chance to see a hole on the front part, and this is a direct defect in the work.

Do not nail the planks together

You may find advice to connect all the elements with the letter P before installing the extensions in the door frame. We do not recommend doing this for two reasons.

- Firstly, it does not reduce, but increases installation time.

- Secondly, the connection is “flimsy”; during the movement and installation of the structure, the nails will still move a little and a gap will appear between the horizontal and vertical extensions. In any case, it will need to be eliminated on the spot.

- Thirdly, the structure may become so distorted during transportation that the nails will break the integrity front side doborov. This is a very unpleasant situation; it will never be possible to repair the crack “to its original state.” Experienced master will always see the problem area.

AND last tip. Sometimes there are times when you have to invite a specialist to help. You install several yourself door trims, and a few must be installed by the wizard. Perhaps you want to finish this stage of building a bathhouse as soon as possible, or you don’t have enough time, your vacation is ending, but you want to finish finishing the bathhouse as soon as possible, the reasons may be different.

The master has come - look what tools he has. If they are dirty, it is immediately obvious that they are not being looked after - refuse the services of such a master. If among his tools you see sealants for cracks, shake the “craftsman’s” hand and send him back. Modern doors made of MDF must be installed so accurately that the presence of cracks only indicates carelessness, inexperience or irresponsibility of the master.

Video - Installing a door extension

When replacing doors in a private house or apartment, you often have to install the doors yourself. Naturally, they can be replaced with platbands or slopes can be made, but it will not look as impressive as a correctly selected and established extra. Therefore, every novice master should know how to install extensions on interior or entrance doors in order to do it himself, thereby saving time and the family budget.

When purchasing a ready-made door frame, its thickness may not correspond to the thickness of the wall in the room. Then you have to install an additional board. This is a special plank made of solid wood, fiberboard or MDF, which can have a thickness from six millimeters to three centimeters. Its width can be different, depending on the size of the section of the wall that needs to be covered with additional cover.

Types of extras:

- A simple extension is a regular extension strip, up to 25 centimeters wide. May be different colors, from which you select the one most suitable for the decoration of your door.

- A telescopic extension is a set of planks that can be inserted into one another due to the presence of grooves and ridges. Thus, by connecting the planks, you can cover any section of the wall.

- Combined boarding is an additional board 2-5 centimeters wide, connected to a platband. Installed only where it is necessary to veneer small area walls.

Before installing the extension, you must take the most accurate measurements possible, since the thickness of the walls may not be the same everywhere.

Correct installation of interior doors with your own hands

When starting to install the extension, you must first install and secure the door block. Most door frames have a ready-made groove for installing additional boards, but some models do not have it. Therefore, the installation technology will be different.

Installing the extension into a box with a groove:

- The groove intended for picking up is completely cleared of residues polyurethane foam or other finishing materials;

- Then the top bar is inserted into the recess for fitting, the necessary marks are made on it and connected to each other by a straight line;

- The board is cut evenly with a jigsaw or sawmill;

- The side extensions are adjusted in the same way;

- Wedges can be placed between the frame and the extension for a more precise fit;

- Next, the extensions are inserted into the grooves and filled with polyurethane foam along the contour.

If there is no recess in the door frame, you can cut it out yourself using a router.

Methods for installing additional strips in a box without grooves:

- Fastening can be done to wooden blocks, screwed to the wall and located at the same distance from each other;

- Installation of additional elements is carried out by attaching them to box beams using self-tapping screws;

- WITH outside a strip is driven in around the entire perimeter on which the extensions should be secured.

How to attach a telescopic extension to an interior door

The technology for installing telescopic extensions is practically no different from installing extensions in a box with grooves. Only the extension of the planks takes place in stages, and the installation of each subsequent batch is carried out after the polyurethane foam has completely hardened.

It is strictly not recommended to install a fully assembled shield, since after applying the foam there is a high chance of gaps forming between the planks. This method of installing a telescopic extension can only be carried out professional builders when using special slats.

Advantages of telescopic extension:

- A doorway decorated with additional strips looks impressive in any interior;

- Can even be used on expanding doorways;

- Thanks to the addition, the slopes do not get dirty or destroyed;

- A large selection of shades allows you to choose telescopic slopes to match the color of the doors.

The adjustment of the planks must be done extremely carefully so as not to damage the recesses and ridges of the fasteners.

Quick installation of extensions and trim on interior doors

Extensions with platbands are installed quickly and easily because they do not need capital fastenings. They just need to be inserted into the recesses of the box. This perfect solution for narrow doorways.

Work order:

- The upper additional strip is adjusted exactly to size;

- Side trims are cut only at the bottom to the required height;

- All elements are tightly inserted into the grooves.

The side trims cannot be sawed off from above, because there are grooves there for attaching the top strip.

Close attention should be paid to adjusting the corners, otherwise the platband may become crooked and ruin appearance doors.

Professional installation of extensions on interior doors (video)

In order for a door with an extension installed on it to look aesthetically pleasing, it is necessary not only to correctly calculate all the dimensions, but also to correctly install the extension strips. You should also think about the design in advance: if the store doesn’t have a selection that matches your door, then you can take strips of contrasting color that will look perfect in the interior. By following all the advice of professionals and following detailed instructions, you can easily install additional elements of any complexity. If the walls are not too smooth and have a big difference in thickness, then there is a reason to install plastic slopes with a wood pattern or to match the color of the walls.