Final stage construction of a house - arrangement of the roof. Traditionally, a gable roof is erected for any residential building, and a single-pitch roof is erected for outbuildings. Technological processes The work of installing, fastening and arranging a roof with a rafter structure in a gable roof version has been perfected for centuries, and these operations do not change depending on the type of roofing materials (clay tiles, corrugated sheets, metal tiles, asbestos slate, metal or plastic).

Types of gable roof

People say: “a roof like a house,” that is, they mean not only the shape, but also the reliability of the structure, which has a long list of advantages:

- A variety of roofing scheme options and architectural roof shapes;

- Simple calculations and cost-effectiveness of the roof;

- Natural runoff of precipitation;

- Simple geometric shapes of the roof ensure a low probability of water accumulation and roof leakage;

- Large usable attic area, it is possible to make an attic;

- Good maintainability, high strength, durability and wear resistance of a roof made of two slopes.

The three most common options for a gable roof:

- Symmetrical gable roof: This is the most popular solution due to its absolute reliability and ease of execution. Symmetrical slopes evenly distribute all loads on the mauerlat and walls of the house. The choice of roofing material does not depend on the type and thickness of the thermal insulation layer. The load-bearing load can be easily increased by making the rafter system from thicker timber; the jibs and spacers can be attached anywhere. Negative factor - a full-fledged attic will not work in such an attic - either there will be low sloping walls with many “dead” zones, or a small but rectangular room;

- Asymmetrical roof of two slopes: Different slope angles reduce usable area attic, but on one side you can make a full-fledged living space. Because of different angles roof slope, the load on the load-bearing walls and foundation of the house is distributed unevenly, which requires recalculating the load-bearing capacity of the base and load-bearing walls of the house, recalculating the types of materials and their quantities, as well as changing the methods of insulation, waterproofing and finishing;

- Asymmetrical gable roof with internal or external bend: Allows you to design living spaces without regard to the roof structure. The disadvantages are the same as in the paragraph above.

Preparing to build a house roof

The shape of the roof and its design can be selected based on the size of the building, the material of the load-bearing walls, and the geographic location of the site. These and other parameters specified in the project determine what loads a gable roof can withstand during operation.

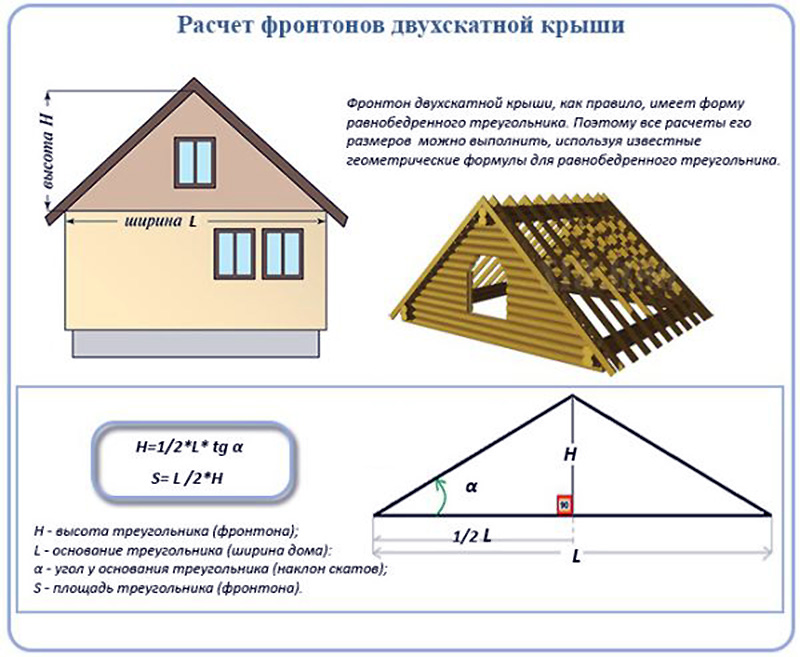

The slope angle of the slopes has a certain optimal range, in which weather conditions have the least influence on the formation of maximum loads on the roof. If the slope angle is ≤ 400, then this limits the possibilities of equipping an attic or a full-fledged room in the attic, and a slope angle ≤ 100 increases the load on the roof from rain, wind or snow. If you want to definitely have an attic or a room in the attic space, it is better to use the polyline option asymmetrical roof, and if the walls of the house are more than 6 meters long, then the rafter system must be strengthened with additional purlins.

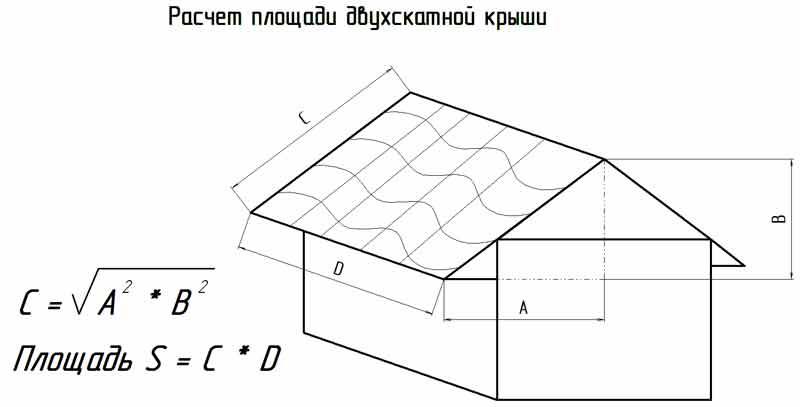

When calculating building materials for gable roof it is necessary to proceed from the axiom that the weight of roofing materials should be as small as possible so as not to load the walls and foundation of the house. Wooden elements will be stronger not only when their cross-section is increased, but also when suitable types of wood are used. Main parameter when calculating materials - the total area of the roof, and a symmetrical structure in this regard is easier to calculate than others - it is enough to know the perimeter of one slope, double its area, and get an accurate result.

The main load from the weight of the roof is borne by the long walls of the house, so the rafter system is built on the principle of distributing the load along the system. Not for home large sizes(≤ 6 m) it is more practical to use a system of hanging rafters (without supports); when building a larger house, a system of layered rafters with more complex configuration.

A finished gable roof for a private house consists of the following elements and components:

- Mauerlat is a wooden (sometimes metal, if the roof will be covered with rolled metal) beam or log that is attached to the surface of the external walls to support the rafters on it;

- A rafter system, the design of which is selected based on the design of the house;

- Struts (diagonal fastening of rafters to each other) and ridges (beams along the roof ridge for fastening the slopes);

- Lathing – used for installation of roofing and hydro-noise insulation elements;

- Insulation and moisture protection;

- Roofing covering.

How to mount the Mauerlat

The Mauerlat along the walls of the house holds the weight of the roof, evenly distributing it over the walls and base of the house. The width of the timber for the mauerlat should be equal to the width of the wall. The timber is impregnated with an antiseptic and substances that increase the fire resistance of the wood. The outer border of the Mauerlat should not protrude beyond the outer edges of the walls.

The Mauerlat is attached in different ways. Steel wire Ø 8-12 mm is laid in the brick wall, holes for the wire are drilled in the wood, and through them the timber is tied to the wall. The timber can also be secured with staples, threaded rods of one or two teeth, metal plates, wooden pegs or anchors through the same holes in the Mauerlat. The gables and lower edges of the sheathing are attached either directly to the mauerlat, or to a beam of smaller cross-section, which is nailed (screwed) to the top trim.

Floor beams

When settling in beam floors For the roof of a private house, it is necessary to use a wooden beam with a cross-section of 200 x 100 mm. The larger the area of the house, the larger the section of the supporting beam should be. Begin the installation of beams by attaching the outermost elements along the long wall of the house. Then the points where the remaining floor beams will be attached are marked.

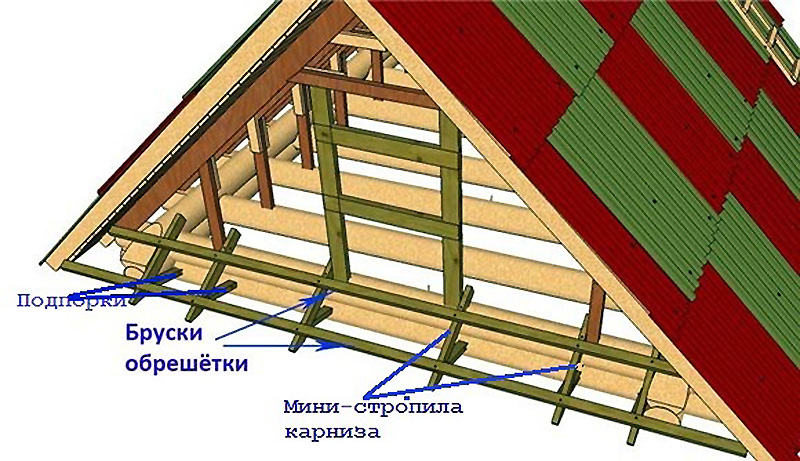

The lathing is mounted on longitudinal beams, which are located at a distance of 50-60 cm, and attached to the mauerlat with nails 200 mm long or any of the above methods. The beams are carried beyond the edges of the walls to a distance that determines the width of the cornice - from 30 to 50 cm. The cornice will be nailed (screwed) from below to these beams. Since a pediment will be installed at the ends of the roof, to attach the cornice and pediment, an insert is made into a groove on the transverse beam of the mauerlat. During construction sloping roof for an attic at the gable it will be enough big square, therefore it is necessary to ensure the design of the ebb and gable overhang.

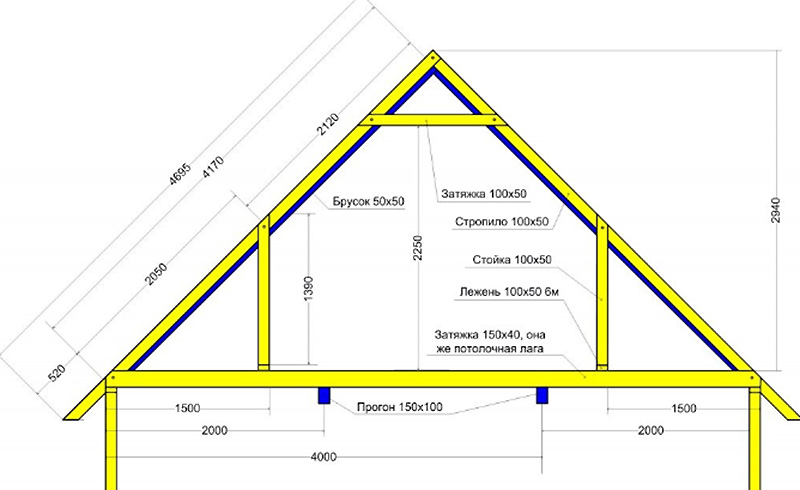

The rafters of a gable roof are several identical wooden beams of the same length and cross-section. After installation of the floor beams, the ridge beam, for which beams with a cross section of 100 x 50 mm are fastened along the central longitudinal axis of the house with spacers. Rack height in standard scheme gable roof is equal to the distance from the floor to the upper surface of the Mauerlat. Instead of timber for the ridge, you can use boards 50 mm thick.

Before installing the rafter system, it is recommended to make a scale template. For this board from truss structure you need to attach one end to the beam, the other to the ridge, and mark its length. This will be the standard length of the rafters.

The rafter system is also installed according to the template, observing the sequence of processes. After installation and securing from the lower end of one rafter beam you need to immediately fasten the opposite rafter and connect the beams with their upper ends to each other through the ridge. The rafters are nailed to the ridge beam, and to the floor beam - with steel brackets or angles, self-tapping screws or anchors. For a roof of any shape with two symmetrical or asymmetrical slopes, boards are fastened lengthwise and crosswise under the rafters to give rigidity to the system.

Pediment and cornice

The pediment is sewn up after the construction of the rafter structure is completed. Modern materials are increasingly replacing traditional wood when sheathing gables, and now they use lining, siding, corrugated board, and other durable decorative finishing materials. Any cladding material is attached to a frame, which is mounted in advance. Regardless of whether or not there is a room or attic in the attic, it is necessary to leave a window opening in the gable - for ventilation and minimal natural light space.

The cornice must be installed around the entire perimeter of the house - it is necessary for moisture and wind protection of the truss structure, the walls of the house and the foundation. Since every self-respecting owner always makes drainage around the perimeter of the house, they are also attached to the eaves, and drain pipes- to the walls. Plastic system The drainage system is mounted on plastic clamps. The bottom of the cornice boards or cornice frame is painted, sheathed with siding, clapboard or corrugated sheeting - in unison with the finishing of the pediment.

The roof is mounted on the sheathing, and, based on the type of roofing materials, the sheathing is first done with vapor barrier, hydro- and heat-insulating materials. For roofing you can use ondulin, metal tiles, ceramic materials, soft tiles, etc.

- Self-tapping screws for roof construction must have the manufacturer’s mark and EPDM gaskets ≥ 2 mm thick, otherwise roof leakage cannot be avoided;

- Poor-quality protective coating of fittings will quickly collapse under the influence of weather conditions, which will lead to leakage at the fastening points and unsightly appearance in the form of rusty or dirty spots;

- The absence of a snow retention system means the possibility of unexpected snow falling off the slopes, which can lead to failure of the roofing and drainage systems;

- Poor ventilation leads to the formation of condensation in the under-roof space.

You will be able to build a reliable house if you build a high-quality roof for it. To do this, choose a good project, calculate how many materials will be needed to build this or that part of the house. Fasten the rafters of your gable roof conscientiously.

Do not forget that you will need to make high-quality waterproofing throughout the house and on the roof, and insulate your home. Choose the best roofing material you can afford. For each type of roof, rafters are made differently.

You don't have to build it the way you see fit. There are certain, proven technologies for building houses. Read the instructions, buy necessary materials and start building your home yourself or with help.

For example, according to standards, a rafter system is considered reliable when it can withstand a pressure of 200 kg per m2. First, decide what type of roof you will build over the house, and then study the features of installing rafters for it.

In this article

How to add strength to a rafter system?

Ideal when you built a country cottage with your own hands. You can choose the house design and room layout that you like. Personally choose and order quality material and take part in all stages of construction and then arrangement of your home. It will be a pleasure to live in such a house, where every corner is familiar.

About rafter legs

A large load falls on the rafters - the weight of the roof. They must be of high quality, reliable and well attached.

Layered rafters include the following materials:

- Lezhni;

- Rafter legs;

- Racks;

- Struts.

Rafter legs are medium-thick bars. They are installed along the slopes. It is the rafters that keep the roof from sagging in one place or another. The load of the covering weight is distributed to other parts of the roof.

Structures are made layered when there are too large girders between the pillars located vertically. When you are provided with a project, the pitch between the rafters will already be calculated. The rafters on a gable roof must be fastened in such a way that after installation the roof remains strong and lasts a long time. There are racks here that similarly support the roof.

Types of rafters

The rafters are included in the roof frame and can be of their own specifications. characteristics sloping and hanging. Let's take a closer look at each type:

- The layered ones have supports under the 2 heels and are reliable. The rafters are fastened to the mauerlat in such a way that the lower end rests on the mauerlat or on the upper crown of the frame located on the ceiling. The lower one can rest on another rafter located in the purlin. This beam is horizontal and lies under the ridge. In the first case, the rafter system is spacer, in the second - non-spacer.

- Hanging rafters rest against one another with their tops. And the bottom is located on another beam, which is called a tie. It connects the heels located below the 2 rafter legs. This results in a triangle, which is called a roof truss. Thanks to the tightening, there is no strong stretching of the materials. This means that the load on the walls will only come from top to bottom. This design of rafters is called spacer. Its advantage is that it does not create additional load on the walls of the house.

When you purchase beams for rafters, don’t be too lazy to drive up to the warehouse. The wood should be seasoned, not wet, smooth and not chipped, with no signs of mold or that a bug has worn it down. Buy only high-quality material, discard the bad ones. Then you will treat the beams with an antiseptic composition so that they do not become moldy or damaged by insects.

We fasten the roof bars

The beds serve as supports for the bars and this is how the girder is supported. The rafter legs will rest against the mauerlat at one end, and at the other against the purlins. They are attached to the latter.

The struts are made to make the rafter legs even more stable.

Make sure that the connections between the parts are strong and reliable. Attach the parts to each other:

- Insertion method;

- Nails;

- Anchor bolts;

- Self-tapping screws are used.

Fastening methods

When you just start building a roof, you need to attach a Mauerlat around the perimeter of your walls. What it is? A large beam, it is attached to the load-bearing walls of the house using anchor bolts. Mauerlat is the basis for a roof with rafters.

Before assembling the truss, you must carefully trim all the strips with beams and bars. They are cut obliquely.

At the top, where the base of the mauerlat is, the rafters need to be fastened end-to-end using screws. Want to avoid cracks? Drill a hole slightly smaller in diameter than the screw itself.

The most popular slings are made of wood. They are preferred by the vast majority of those under construction. The material is light but durable. Both an experienced builder and a beginner who decides to build a house on their own can work with it.

We install rafters on a gable roof ourselves

Many people make this design when the rafter legs hang down. The system is good for both home and bathhouses. Some work can be done on the ground, and then the material can be lifted and secured to the installation site. Relatively little lumber is used for such a structure, which will allow you to save money.

You need 1 triangle of rafters, which is made according to clear dimensions and adhering to the rules. The completed rafters, which will have well-measured and fastened crossbars with ties, are pulled onto the roof. Here they need to be placed in certain places vertically and very evenly. They are attached to the ridge with the Mauerlat.

If the roof slopes are longer than 4.5 m, then in order for the system to be stable and more reliable, the racks must be installed in a vertical position. One of their ends will support the rafter leg, 2 will rest directly on the beam located on the ceiling.

Do this and it doesn’t matter what kind of rafters you installed: layered or hanging. When slopes are added to a structure, it becomes stiffer. Do not forget that the rafters are most often attached to a ridge beam with a Mauerlat. The result will be a reliable gable house.

How to avoid additional calculations?

Entrust the creation of a house project to a professional. He will tell you what cross-sectional diameter the beams are needed, the length of the planks and other parts. After all, the specialist knows that the roof is held in place by the rafter system. It bears the heaviest load and requires correct calculations and high-quality building materials.

It’s better not to ask advice from house builders like yourself. Yes, they built their house, but how strong is it? Not known.

It is best to contact a foreman you know and ask him for practical advice. After all, he owns the documentation. There are clear standards permissible load per 1 m2, which must be adhered to when building a house. The documentation states what load is given and what material can handle it.

Take a notepad and pen to your meeting with the foreman and immediately write down his advice. So, you definitely won’t forget anything or mix it up. Build it the way he expertly recommends.

For two pitched roofs Most owners make rafters from wood. Choose the one that has been aged. Now treat it carefully so that mold does not form or a bug can undermine it.

When you assemble the structure, make sure that the angle between the rack and struts is no more than 45 degrees. The timber beams need to be cut diagonally so that the construction truss tilts at an angle of 40 degrees.

The rafter parts can be fastened to each other not only with brackets, but also with corners. Purchase metal corners of a suitable size to attach the rafters to the mauerlat. The latter in any of the parts must be strong and reliable. Parts of the system can be connected to each other using nails with cutouts, corners with screws, and other devices.

When you're putting up the roof, don't fuss. Everything needs to be done carefully and thoroughly. After all, even wooden frame houses last at least 50 years, and log houses - 100 years.

Your task is to adhere to technology, not to make mistakes anywhere, so that the roof does not become warped after a year or 5. Consult with craftsmen and experienced comrades who have already made roofs for themselves or to order and build the roof little by little.

The rafter system is the supporting load-bearing frame for the roof. That is why it must be reliable, since the durability of the entire structure directly depends on the quality of the material from which the system elements are made, and the professionalism of its assembly.

It is quite possible to manufacture and install it if you have a craftsman nearby who has dealt with similar work more than once. Without experience in this work and a reliable adviser, it is dangerous to undertake it yourself - it is better to entrust this undertaking to a team of qualified craftsmen. However, if you still decide to try your hand, then you need to approach all the details of the system with all responsibility and caution, since the work is not only difficult, but also quite dangerous.

Requirements for rafters

In order for the entire roof system of the house to serve for a long time, dried wood is selected for the manufacture of its elements coniferous species. For the rafters you need a beam with a size of 100÷150 × 50÷60 mm.

Coniferous wood is light in weight, which is beneficial for the entire construction of the house, since a heavy rafter system, creating a lot of pressure on the walls, can lead to their damage and destruction.

Another plus coniferous material for the construction of a foundation for a roof, there is a high percentage of foliage in its structure, which means an increased ability to withstand atmospheric moisture.

To manufacture elements of the rafter system, it must meet certain requirements that directly affect the durability of the entire structure:

- The wood for installing the rafter system must be seasoned, which will eliminate the risk of its deformation in the structure.

- Wood moisture content should be no more than 2-2.5%.

- If a hanging rafter system is being installed, then for the tie-downs and the rafters themselves, be sure to use only first-grade wood.

- When constructing a layered system, the second grade of material is also suitable.

- For supporting elements - racks and struts, you can use a third grade of wood, however, trying to choose raw materials with a minimum number of knots.

- The exact thickness of the blanks is selected depending on the weight of the selected roofing material and the weather conditions in the given region. This is especially true for the maximum thickness of snow cover in winter period. For example, for middle zone Russian regions, it is necessary to calculate the load per 1 kv.m. roofs 180÷200 kg.

- In addition, the parameters of the rafter legs depend on the overall dimensions of the rafter system and its slope.

- Before installing the system, the wood must undergo antifungal and fireproofing treatment.

When installing a structure, you need to know and types of loads that the entire roof system is subjected - they are also taken into account when choosing rafter parameters and installing the structure.

- Temporary loads are the weight of a person at repair work roofs, snow cover in winter and the strength of wind gusts. this is the weight of roofing, insulation and insulation materials.

- TO special types loads include seismic impact if the structure is located in earthquake-prone regions.

General design of the rafter system

The most widespread The rafter system has the shape of a triangle and is intended for arrangement. It includes several triangular elements consisting of two rafter legs and auxiliary supports and ties. Each such triangular structure is called a rafter. The triangular elements of the system are located at a certain distance from each other, and most often it ranges from 50 to 80 cm.

This form has become traditional, as it creates better rigidity and reliability of the structure. It can end at the level of the walls or be continued to install overhangs, which can be 40 centimeters or more in length. Sometimes rafters ending on the walls are extended with additional bars - “fillies”.

So, as mentioned above, the rafters are one triangular section, including:

- Two rafter legs connected on a ridge beam, or without its use, directly to one another.

- Struts or rafter legs are spacers that support the rafter leg and relieve the load placed on it. They rest against the bed and are secured to it.

- Racks or vertical supports, consisting of bars. They, like the spacers, support the rafter leg, but closer to the center of the triangle. The stand is installed on a bench.

- A crossbar is a board that holds two rafter legs together.

- The scrum is two crossbars attached to both sides of the rafter leg. It performs the same task as the crossbar - it gives rigidity to the structure.

- Headstocks are a vertical block that is supporting and is installed in the middle of the triangle, resting against the floor beam and supporting the ridge. This part is used in hanging rafter systems.

- Purlin - it connects individual rafters into a common system. They are located parallel to the wall.

- Ties are floor beams that connect the rafter legs, completing the rafter triangle.

- - a powerful beam installed at the upper end of the wall structure, to which elements of the rafter system are subsequently attached.

There are three types rafter systems- this is layered, hanging and combined, i.e. including elements of both one and the other.

Hanging system

The hanging rafter system is used to cover buildings without internal main walls. The rafter legs are laid on a mauerlat attached to load-bearing walls.

Since such a system experiences a large load, which is transferred to the load-bearing walls, the following additional elements are used to relieve this stress:

- A tie that simultaneously acts as a floor beam. It can be used for flights up to 6 meters. If the span is larger, then it is raised higher along the rafter leg, and in the lower part the triangle is also closed with a floor beam.

- The headstock supporting the ridge is required if the span between the load-bearing walls is more than eight meters.

- Struts extending from the headstock at an angle and supporting the rafter legs.

- Help that strengthens the rafter leg.

- A ridge beam is required in this system.

All elements are fastened together with metal corners, brackets or screwed together.

Layered system

The layered system is more stable and reliable, thanks to additional supports in the form of permanent partitions inside the building. Their presence makes it possible to make attic extra room.

When making such a decision, the racks in the rafter system are installed closer to the load-bearing walls, freeing up space.

In this system, the rafter legs are installed on a mauerlat, which is secured to the side load-bearing walls. To ensure reliable installation, special grooves are cut into the rafter legs, and the elements are fastened together with brackets.

A ridge beam in this system is desirable if there is a large span between the load-bearing walls, and it is planned to arrange a living space in the attic. The same applies to the ties, which in this case are fixed at the ceiling level of the future room.

You also need to know that the Mauerlat must be very securely fastened to the wall with pins going 350÷400 mm deep into the wall, since it bears a large weight and dynamic load from the entire rafter system.

If it is assumed that the main walls of the building may shrink slightly, then the lower parts of the rafters are attached to the Mauerlat with sliding fasteners, allowing the element to take the desired position without causing harm to either the walls or the entire rafter system.

Video: installation of a gable roof rafter system

Prices for various types of timber

Installation of truss structure

Having prepared suitable material and having a design for the roof structure, you can begin its installation.

Gable roof

On load-bearing walls, mauerlat bars are fixed to a pre-laid waterproofing material - roofing felt, and the installation of rafters is marked on them. It is very important to mark the two sides of the installation equally, otherwise the rafters will be skewed.

- The first rafters are adjusted and rigidly fastened directly at height, so as not to make mistakes in fastenings and in selections for installation on.

- Then, they are lowered down, and all other rafters are made according to the first sample. On the ground it is much easier and safer to fit all structural elements to each other and make reliable fastenings.

- When sawing timber for rafters, you need to leave a small margin, i.e. make them a little longer than required so that you can adjust them to fit.

- To make it easier to navigate, when setting up the first rafters, take a beam whose length is equal to the distance between the outer edges of the walls - this will be the base or hypotenuse of the future triangle.

- The middle of the block is determined, and a perpendicular board is temporarily nailed to it, having a height from the front wall of the structure to ridge - peaks equilateral triangle.

- Then they are laid out and secured sides - legs triangle, they are also rafter legs.

- If a hanging rafter system is chosen, then the ties are immediately marked and secured.

- If it is intended to install additional fasteners, then they are fixed in place after installing the rafters on the roof.

- Next, the first rafters are first raised and temporarily installed. On each of them, places are marked where rectangular selections will be made to secure them to the Mauerlat.

- Then, the rafters are lowered down again, and grooves having a right angle are cut out on them.

- Using the first pair, taking it as a sample, the same grooves are measured and cut out on the remaining rafters.

- Next, two triangles are climbed onto the walls, which are installed at the beginning and end of the future. If a ridge beam is provided, then both installed parts are immediately connected with it.

Video: how rafters are attached to the Mauerlat

- Along each slope, cords are stretched between the already mounted rafters, which will also serve as guides for aligning the remaining parts of the structure.

- The first installed rafters are immediately reinforced with racks, struts and other elements of the system that provide rigidity and reliability of the structure.

- Next, the remaining rafter pairs are raised and installed.

- If necessary, they are connected to each other by purlins and beds.

- When installing a rafter system, all its elements are fixed temporarily, since some of them may have to be adjusted and reinstalled later. They are firmly attached only after the entire system has been aligned. Then corners, brackets are used for fastenings, and, if necessary, sliding elements. Self-tapping screws, nails, bolts, staples and studs are used at various joints.

If necessary, the rafters can be extended with “fillies”

If necessary, the rafters can be extended with “fillies” - After the system is basically installed, the rafters can be “filled” on the overhangs - this is done so that the walls of the building are as well protected as possible from moisture getting on them during rain.

- The next stage of work is the installation of lathing on top of the rafters. The thickness and width of the boards for this part of the structure are selected taking into account the installation technology of the selected roofing material - this will depend on the width, weight and length of its sheets.

Video: installation of a gable roof rafter system

Prices for various types of fasteners for rafters

Rafter fasteners

Single slope systems

It is generally accepted that a lean-to system is used only when constructing roofs for garages, sheds, gazebos and other non-residential buildings, but this is not at all true. This type of roof also serves well as a covering. residential buildings, and you can even arrange an additional warm room under it if you correctly calculate the slope of the structure.

A shed system can be considered as half of a gable roof, but with some deviations. For example, if when installing a gable roof, the gable part is the width of the building, then with a shed roof it is its length.

The pediment can be raised from brick or wooden beams and boards. Its height will depend on the selected roof slope. The roof gable is raised high if an additional room is built underneath.

Rafters in this system are easier to lay, but if the distance between the walls is large enough, then it is still necessary to install additional supporting elements for rigidity.

To correctly determine desired angle slope, you need to rely on the following factors:

- Snow depth in winter and average precipitation in other seasons.

- The weight of the roofing covering that is planned to cover the rafter system.

- Temporary loads, in the form of gusts of wind.

The angle of this type of roof can vary from 5 to 45, and sometimes there are buildings with an angle of even 60 degrees.

Installation of the single-slope option is carried out on site, i.e. at a height, since the gable and back wall buildings.

If the roof slope in a one-story mansion is not too large, then the rafters can be extended forward from the front or rear side of the house. This is done in order to arrange a veranda or terrace under the roof.

Attic systems

The most difficult to perform - attic systems roofs

The most difficult to perform - attic systems roofs If the project immediately includes making the attic of the house residential, then you can choose one of two roof designs. The choice will depend on the desired attic area and ceiling height. It can be a gable roof with a high ridge or a broken mansard roof.

Gable roof

In order to arrange an additional room under a gable roof, the space must be free from various additional fastenings. Therefore, you will have to make do with a minimum number of them.

Stands and ties will be mandatory in this design - they will also perform the functions of the sheathing on which it will be attached. finishing material walls and ceiling of the created room.

But in this case, it is very important to use massive beams for the floor beams, which will easily support the weight of the rafter system with insulation and roofing material, plus the entire load given by the pieces of furniture that will be installed in the room. In addition, it is necessary to install the floor beams at a short distance from each other, which should not exceed 50 ÷ 60 cm, but in order for the walls of the building to withstand the entire load without problems, they must be quite massive and strong.

Installation of the system takes place in the same sequence as a gable roof.

Attic “broken” structure

The mansard roof structure of a house is more complex than a conventional gable roof, but its advantage is that the living space resulting from its installation will be much larger and the ceiling will be higher.

Approximate diagram of an attic “broken” system

Approximate diagram of an attic “broken” system This type of roof is called broken, since the system consists of two parts, in each of which the rafters are located at a different angle.

The side rafters can be located at an angle of 30 or 45 degrees from the vertical - this is the most common option for their installation.

The top is fixed at an angle that can vary from 5 to 30 degrees from the horizon.

IN attic structure Both rafter systems can be used. It is preferable to arrange the lower rafters using a layered system, but if the building does not have permanent partitions, then a hanging system can also be used. In the latter case, the attic floor beams, as well as the rafters, should be installed at a distance of no more than 50-60 cm from each other. It should be noted that the walls must be well reinforced, since the load on them will be quite serious, much more significant than when installing a gable roof.

- The construction of the lower rafter system begins with the installation of racks, secured with strapping at the top and at the bottom with floor beams. The distance between the rack systems will be the width of the room, and their height determines the height of the room.

Beginning of installation - installation of two rows of racks

Beginning of installation - installation of two rows of racks - This frame will determine the placement of the remaining elements of the system.

- Next, you need to find the middle of the distance between the rows of racks, and this will determine location in the upper part of the attic. A vertical beam is installed in this place, the same height as the rack system.

- Then, the side rafters are installed and secured to the rack frame and beam overlap, thus creating triangles in which the stand and beam the overlaps form a right angle.

- When all the side elements are installed, begin installation of floor beams; they are also attached to the frame bar and the end of the side rafter. The diagram of this bundle is shown in the first figure in this section.

- Next, the floor beams are connected to each other by a horizontal rail, which is placed on top of them, in the middle of the structure.

- Ridge rafters are installed and supported by struts. They are attached to the rail connecting the floor beams.

- On a ridge, the rafter legs can be fixed to a ridge board or connected to each other with a metal or wooden overlay

- Sometimes, for structural rigidity, a supporting headstock is installed between the ridge and the floor beam.

- The gable walls with openings for windows are lathed. If the entrance is from the street, then on one of the gables, in addition, there will be an opening for a door.

- Further, if necessary, the entire rafter system is sheathed with sheathing or plywood, if the roofing material is chosen soft roof, for example, flexible tiles.

Video: example of installation of a roof truss system

It is not at all necessary to equip the rafter system Just, and you can’t cope with this work alone - you will need at least two assistants. It is desirable that at least one of the invited craftsmen have some experience in this field of construction.

The rafter system of a gable roof is considered one of the simplest in purely structural terms. It consists of only a few elements, the number of which decreases or increases due to the size of the roof itself. But despite its apparent simplicity, the process of erecting a gable roof requires knowledge of some nuances that affect the quality of the final result.

Rafter system for a gable roof

What is a gable roof?

From the name it becomes clear that the roof structure consists of two slopes with rectangular shape in a plane. More often, the slopes have the same dimensions, but there are so-called asymmetrical designs in which the slopes differ in size from each other.

In this case, the slopes are installed to each other at a certain angle, which is called inclination. The line of contact is the ridge beam, which is part of the rafter system. Simply called the ridge, it is the highest point of the roof.

The side planes formed by the slopes are called pediments. They have a triangular shape. After constructing the roof, the sidewalls are lined with sheet or panel materials: plywood, OSB, even boards, etc.

What is a gable roof rafter system?

The basis of the structures of the slopes are the rafter legs, also known as rafters. They are made either from lumber (timbers, boards), or from steel profile(corner, channel). Wood is used in private house construction. It’s easier to work with, plus the lumber is cheaper.

The construction of a gable roof rafter system is not only about rafters. In addition to these, there are several more required elements. The photo below shows all the elements of a gable roof. Let's label them.

Each roof element has its own purpose

Elements of a gable roof rafter system

Mauerlat. Essentially, this is a beam on which the rafters rest. Its purpose is to evenly distribute the loads from the rafter legs onto the walls of the house. If the Mauerlat is not used, then the rafters will put pressure on the walls pointwise, that is, large stresses will arise at the installation sites, which will lead to cracking of the walls.

Rafters installed at an angle.

Horse, aka ridge beam or purlin. Its task is to form the joining point of the rafter legs. Ridge beam is an optional element of a gable roof. There are designs in which it is not installed. But more on that below.

Puffs. They are not always used, but only on hanging rafters or if the rafter system is installed on a wide house.

Floor beams, which form the ceiling in the room and the floor in the attic.

One of the floor beams, called let's lie down. It additionally serves as a base for the support posts that support the rafters. Not always used.

Support posts, they are also the headstocks that support the rafter legs. They are installed only if the span of the house is at least 6 m.

Struts, they are also diagonal supports. They are used only if the support posts cannot ensure the overall reliability of the rafter system.

There is one more element that is clearly visible in the photo below. These are support posts for the ridge girder. They are installed if the structure of the rafter system is heavy. That is, the entire structure is assembled under heavy roofing material, for example, ceramic tiles.

Layered rafters with support posts under the ridge girder

You might be interested! Warm roof– this is an important detail when building an energy-efficient house. From the article at the following link you can find out.

Types of rafters

The roof rafter system (gable) can be assembled from layered or hanging rafters.

Layered

They got their name because their lower ends rest on the walls of the house, and their upper ends rest on the ridge girder. Wherein rafter elements are subjected to loads that bend them. The design is reliable, durable, with high load-bearing capacity.

The photo above just shows a layered rafter system. It is clearly visible that the legs rest on the ridge at the top. In this case, there are two types of fastening of the rafters themselves in the upper part:

fastening is done to the ridge:

fastening is done to each other with emphasis on the ridge (photo above).

Hanging

It is necessary to immediately indicate that this type rafter system can be used if the distance between the walls of the house does not exceed 12 m. Because the rafters rest with their lower ends on the walls, and their upper ends only with each other (there is no ridge girder in the design). Hence the low load-bearing capacity with a large spread.

The hanging rafters for the roof have one clear design flaw– large supporting load on the walls of the house. To reduce it, strings are installed between the legs to form a rigid triangle. Often the functions of tie bars are performed by load-bearing floor beams.

If it is necessary to strengthen the hanging rafters, racks and struts are installed under them.

Hanging rafters of a gable roof

Installation of a gable roof rafter system

Two types of rafter systems determine two types of assembly technology. Let's look at each one separately.

Installation of layered rafters

There is a certain sequence for assembling layered rafters.

Two outer support posts are installed under the ridge beam. They will not only support the timber, but will also be the elements that form the gables of the building. They are attached at the bottom to the Mauerlat. In this case, they are strictly aligned vertically, and the upper ends are in one horizontal plane. To do this, stretch a strong thread between the posts and check it with a level to ensure it is horizontal. If there are deviations, then one of the supports (low) is raised using wooden supports.

Intermediate support posts are mounted along a horizontally stretched thread in increments of 2-2.5 m. To prevent the beams of the posts from moving, they are supported with temporary fasteners: supports or tie-downs.

A ridge beam is placed on the racks, which is also attached to them.

Produced in pairs installation of gable roof rafters. Installation can begin from any side. The fastening is carried out immediately to the Mauerlat and to the ridge. The main thing is to maintain the distance between the legs, which is determined depending on the severity and bearing capacity roofing material. Usually this parameter is indicated in the house design.

If necessary, intermediate support posts and struts are installed.

Installing rafters on a ridge along a tensioned thread

Installation of hanging rafters

The technology for installing hanging rafters is different. To do this, the entire structure, assembled from two rafters and a tie, is assembled on the ground. That is, roof trusses are prepared in the required quantity, which are then lifted onto the roof. Sometimes craftsmen assemble roof trusses. They assembled one, installed it, and assembled the next one.

It should be noted that such farms have a significant mass. Lifting them manually is difficult and dangerous, so they use the services of a crane. And this increases the cost of construction.

Hanging roof trusses assembled on the ground

The most difficult thing is to display the farms. All of them are installed at the installation site with a planned step, where they are temporarily secured with jibs and supports. Then a thread is stretched between the outer trusses. It must be positioned so that, firstly, it is stretched strictly along the horizon, and secondly, along a structure that is higher than the rest.

All that remains is to raise the rafter structures that are below the tension level. And the last thing is the installation of the sheathing, which will secure all the trusses into one rafter system. Please note that in the lower part of the rafters will be fixed to the Mauerlat.

This might interest you! When the installation of the rafter system is completed, it’s time to roofing works. From the article at the following link you can find out.

Calculation of rafters

length of rafter legs;

step of their installation;

cross-section of the lumber used.

With length, everything is simple; for this you will have to use the Pythagorean theorem, which is based on the formula: c 2 =a 2 +b 2, where c is the hypotenuse of the triangle (this is the rafters), a and b are the legs. The latter are the height of the roof and half the width of the house. All parameters can be easily measured.

The length of the rafter is l 2 +H 2

The installation pitch is more difficult, because much will depend on the weight of the roofing material and the loads from natural precipitation. The greater both loads, the smaller step installations. But, as practice shows, this parameter varies from 60 cm to 2 m. The latter indicator is used if corrugated sheeting with large corrugation parameters, for example, H75, is used as a roofing material.

As for the cross-section of the rafter legs, here, as in the case of the installation step, the loads are taken into account, as well as the length of the legs and the step of their installation. Here the relationship is as follows: the greater the load, pitch and length, the larger the cross-section.

Video description

In the video, the installation process of the rafter system:

And one moment. Rafters for a gable roof are laid at a certain angle (indicated by the letter “a” in the photo). The slope is selected based on the choice of roofing material. That is, some coatings cannot be laid on roofs if the angle of inclination is less than the required one. Here are some ratios:

the minimum angle of inclination of the rafter system for slate is 22°;

for corrugated sheets – 12°;

for metal tiles – 14°;

soft tiles – 15°.

Ratio of roof slope to type of roofing material

On our website you can find contacts construction companies who offer turnkey roof design and repair services. You can communicate directly with representatives by visiting the “Low-Rise Country” exhibition of houses.

Generalization on the topic

Gable roofs are traditional designs. But from the article it becomes clear that there are two rafter systems that form the basis for the construction of roofs. The one that fits the size of the house is selected. The loads pressing on them are also taken into account as a selection criterion. Therefore, it is important to correctly correlate everything, taking into account the nuances of construction processes.

Rafters perform a number of significant roofing functions. They set the configuration of the future roof, absorb atmospheric loads, and hold the material. Among the rafter's duties are the formation of smooth planes for laying the covering and providing space for the components of the roofing pie.

In order for such a valuable part of the roof to flawlessly cope with the listed tasks, information is needed about the rules and principles of its design. The information is useful both for those who are constructing a gable roof truss system with their own hands, and for those who decide to resort to the services of a hired team of builders.

Wooden and metal beams are used to construct the rafter frame for pitched roofs. Source material For the first option, use a board, log, timber.

The second is constructed from rolled metal: channel, profile pipe, I-beam, angle. There are combined structures with the most heavily loaded steel parts and wood elements in less critical areas.

In addition to its “iron” strength, metal has many disadvantages. These include thermal qualities that are unsatisfactory to owners residential buildings. The need to use welded joints is disappointing. Most often, industrial buildings are equipped with steel rafters, and less often, private cabins assembled from metal modules.

In the matter of independent construction of rafter structures for private houses, wood is a priority. It is not difficult to work with, it is lighter, “warmer”, and more attractive in terms of environmental criteria. In addition, to perform nodal connections you will not need welding machine and welding skills.

Rafters - a fundamental element

The main “player” of the frame for constructing a roof is the rafter, which among roofers is called a rafter leg. Beams, braces, headstocks, purlins, ties, even a Mauerlat may or may not be used depending on the architectural complexity and dimensions of the roof.

Rafters used in the construction of gable roof frames are divided into:

- Layered rafter legs, both heels of which have reliable structural supports under them. The lower edge of the layered rafter rests against the mauerlat or the ceiling crown of the log house. The support for the upper edge can be a mirror analogue of the adjacent rafter or a purlin, which is a beam laid horizontally under the ridge. In the first case, the rafter system is called spacer, in the second, non-spacer.

- Hanging rafters, the top of which rests against each other, and the bottom is based on an additional beam - a tie. The latter connects the two lower heels of adjacent rafter legs, resulting in a triangular module called a rafter truss. Tightening dampens the tensile processes, so that only vertically directed load acts on the walls. Although a structure with hanging rafters is braced, the bracing itself does not transmit to the walls.

In accordance with the technological specifics of rafter legs, the structures constructed from them are divided into layered and hanging. For stability, the structures are equipped with struts and additional racks.

To support the top of the layered rafters, planks and purlins are installed. In reality, the rafter structure is much more complex than the elementary templates described.

Note that the formation of the frame of a gable roof can generally be done without a rafter structure. In such situations, the supposed planes of the slopes are formed by slabs - beams laid directly on the load-bearing gables.

However, what interests us now is specifically the structure of the rafter system of a gable roof, and it can involve either hanging or layered rafters, or a combination of both types.

Subtleties of fastening rafter legs

Fastening the rafter system to brick, foam concrete, aerated concrete walls is carried out through the Mauerlat, which in turn is fixed with anchors.

Between the Mauerlat, which is wooden frame, and walls made of the specified materials must be laid with a waterproofing layer of roofing material, waterproofing material, etc.

The top of brick walls is sometimes specially laid out so that along the outer perimeter there is something like a low parapet. This is so that the mauerlat placed inside the parapet and the walls do not push apart the rafter legs.

Roof frame rafters wooden houses rest on the upper crown or on the ceiling beams. The connection in all cases is made by notches and is duplicated with nails, bolts, metal or wooden plates.

How to do without mind-boggling calculations?

It is highly desirable that the section and linear dimensions wooden beams were determined by the project. The designer will provide clear calculation justification for the geometric parameters of the board or beam, taking into account the entire range of loads and weather conditions. If available home handyman design development no, his path lies to the construction site of a house with a similar roofing structure.

You don’t have to pay attention to the number of floors of the building being constructed. It is easier and more correct to find out the required dimensions from the foreman than to find out them from the owners of a shaky self-built building. After all, in the hands of the foreman is documentation with a clear calculation of the loads per 1 m² of roof in a specific region.

The installation pitch of the rafters determines the type and weight of the roofing. The heavier it is, the smaller the distance between the rafter legs should be. For styling clay tiles, for example, the optimal distance between the rafters will be 0.6-0.7 m, and for corrugated sheets 1.5-2.0 m is acceptable.

However, even if the pitch required for proper installation of the roof is exceeded, there is a way out. This is a reinforcing counter-lattice device. True, it will increase both the weight of the roof and the construction budget. Therefore, it is better to understand the pitch of the rafters before constructing the rafter system.

Craftsmen calculate the pitch of the rafters according to the design features of the building, simply dividing the length of the slope into equal distances. For insulated roofs, the pitch between the rafters is selected based on the width of the insulation slabs.

You can find it on our website, which may also help you a lot during construction.

Rafter structures of layered type

Layered rafter structures are much simpler to construct than their hanging counterparts. A reasonable advantage of the layered scheme is to ensure adequate ventilation, which is directly related to long-term service.

Distinctive design features:

- It is mandatory to have support under the ridge heel of the rafter leg. The role of support can be played by a purlin - a wooden beam resting on posts or on the internal wall of the building, or the upper end of an adjacent rafter.

- Using a Mauerlat to erect a truss structure on walls made of brick or artificial stone.

- The use of additional purlins and racks where rafter legs are required due to the large size of the roof additional points supports.

The disadvantage of the scheme is the presence structural elements, affecting the layout of the internal space of the used attic.

If the attic is cold and it is not intended to organize useful rooms, then the layered structure of the rafter system for installing a gable roof should be given preference.

Typical sequence of work for the construction of a layered truss structure:

- First of all, we measure the heights of the building, the diagonals and horizontality of the upper cut of the frame. When identifying vertical deviations of brick and concrete walls, we eliminate them cement-sand screed. Exceeding the heights of the log house is cut off. By placing wood chips under the mauerlat, vertical flaws can be combated if their size is insignificant.

- The floor surface for laying the bed must also be leveled. It, the Mauerlat and the girder must be clearly horizontal, but the location of the listed elements in the same plane is not necessary.

- We treat all wooden parts of the structure with fire retardants and antiseptics before installation.

- On concrete and brick walls We lay waterproofing under the installation of the Mauerlat.

- We lay the mauerlat beam on the walls and measure its diagonals. If necessary, we slightly move the bars and turn the corners, trying to achieve the ideal geometry. Align the frame horizontally if necessary.

- We mount the Mauerlat frame. The beams are joined into a single frame using oblique notches; the joints are duplicated with bolts.

- We fix the position of the Mauerlat. Fastening is done either with staples to those already installed in the wall wooden plugs, or anchor bolts.

- Mark the position of the prone position. Its axis should recede from the mauerlat bars at equal distances on each side. If the run will rest only on posts without supports, we carry out the marking procedure only for these posts.

- We install the bed on a two-layer waterproofing. We fasten it to the base with anchor bolts, with internal wall We connect with wire twists or staples.

- We mark the installation points of the rafter legs.

- We cut out the racks to uniform sizes, because... Our bed is exposed to the horizon. The height of the racks should take into account the cross-sectional dimensions of the purlin and beam.

- We install racks. If provided by the design, we secure them with spacers.

- We lay the purlin on the racks. We check the geometry again, then install brackets, metal plates, and wooden mounting plates.

- We install a test rafter board and mark the cutting areas on it. If the Mauerlat is set strictly to the horizon, there is no need to adjust the rafters on the roof after the fact. The first board can be used as a template for making the rest.

- We mark the installation points of the rafters. Folk craftsmen for marking, a pair of slats are usually prepared, the length of which is equal to the clearance between the rafters.

- According to the markings, we install the rafter legs and fasten them first at the bottom to the mauerlat, then at the top to the purlin to each other. Every second rafter is screwed to the Mauerlat with a wire bundle. In wooden houses, the rafters are screwed to the second crown from the top row.

If the rafter system is made flawlessly, the layer boards are installed in any order.

If there is no confidence in the ideal structure, then the outer pairs of rafters are installed first. A control string or fishing line is stretched between them, according to which the position of the newly installed rafters is adjusted.

The installation of the rafter structure is completed by installing fillets, if the length of the rafter legs does not allow forming an overhang of the required length. By the way, for wooden buildings the overhang should extend beyond the contour of the building by 50 cm. If you plan to organize a canopy, separate mini-rafters are installed under it.

Another useful video about building a gable rafter base with your own hands:

Hanging rafter systems

The hanging variety of rafter systems is a triangle. The two upper sides of the triangle are folded by a pair of rafters, and the base is the tie connecting the lower heels.

The use of tightening allows you to neutralize the effect of the thrust, therefore, only the weight of the sheathing, roof, plus, depending on the season, the weight of precipitation, acts on walls with hanging rafter structures.

Specifics of hanging rafter systems

Characteristic features of hanging type rafter structures:

- The obligatory presence of a tie, most often made of wood, less often of metal.

- Possibility to refuse to use the Mauerlat. A timber frame can be successfully replaced by a board laid on double-layer waterproofing.

- Installation of ready-made closed triangles – trusses – on the walls.

The advantages of the hanging scheme include the space under the roof free from racks, which allows you to organize an attic without pillars and partitions. There are disadvantages.

The first of them is restrictions on the steepness of the slopes: their slope angle can be at least 1/6 of the span of a triangular truss; steeper roofs are strongly recommended. The second disadvantage is the need for detailed calculations for the proper installation of cornice units.

Among other things, the angle roof truss You will have to install it with pinpoint precision, because... the axes of the connected components of the hanging rafter system must intersect at a point, the projection of which must fall on the central axis of the Mauerlat or the backing board replacing it.

Subtleties of long-span hanging systems

The tie is the longest element of a hanging rafter structure. Over time, as is typical for all lumber, it becomes deformed and sags under the influence of its own weight.

Owners of houses with spans of 3-5 meters are not too concerned about this circumstance, but owners of buildings with spans of 6 meters or more should think about installing additional parts that exclude geometric changes in tightening.

To prevent sagging, there is a very significant component in the installation diagram of the rafter system for a long-span gable roof. This is a pendant called a grandmother.

Most often it is a block attached with wooden pegs to the top of the truss. The headstock should not be confused with the racks, because its lower part should not come into contact with the puff at all. And the installation of racks as supports in hanging systems is not used.

The bottom line is that the headstock hangs, as it were, on the ridge assembly, and a tightening is attached to it using bolts or nailed wooden plates. To correct sagging tightening, threaded or collet-type clamps are used.

The tightening position can be adjusted in the area of the ridge assembly, and the headstock can be rigidly connected to it by a notch. Instead of a bar in non-residential attics, reinforcement can be used to make the described tension element. It is also recommended to install a headstock or hanger where the tie is assembled from two beams to support the connection area.

In an improved hanging system of this type, the headstock is complemented by strut beams. The stress forces in the resulting rhombus are extinguished spontaneously due to the proper placement of vector loads acting on the system.

As a result, the rafter system is stable with minor and not too expensive modernization.

Hanging type for attics

In order to increase the usable space, the tightening of the rafter triangles for the attic is moved closer to the ridge. A completely reasonable move has additional advantages: it allows you to use the puffs as a basis for lining the ceiling.

It is connected to the rafters by cutting with a half-pan and duplicating with a bolt. It is protected from sagging by installing a short headstock.

A noticeable disadvantage of the hanging attic structure is the need for accurate calculations. It is too difficult to calculate it yourself; it is better to use a ready-made project.

Which design is more cost effective?

Cost is an important argument for an independent builder. Naturally, the price of construction for both types of rafter systems cannot be the same, because:

- In the construction of a layered structure, a board or beam of small cross-section is used to make rafter legs. Because layered rafters have two reliable supports underneath them; the requirements for their power are lower than in the hanging version.

- In the construction of a hanging structure, the rafters are made of thick timber. To make a tightening, a material with a similar cross-section is required. Even taking into account the abandonment of the Mauerlat, the consumption will be significantly higher.

It will not be possible to save on the grade of material. For load-bearing elements Both systems: rafters, purlins, planks, mauerlat, headstocks, racks require 2nd grade lumber.

For crossbars and tensile ties, grade 1 will be required. In the manufacture of less critical wooden overlays, grade 3 can be used. Without counting, we can say that in the construction of hanging systems, expensive material is used in greater quantities.

Hanging trusses are assembled in an open area next to the facility, then transported, assembled, upstairs. To lift weighty triangular arches from timber, you will need equipment, the rental of which will have to be paid. And the project for complex nodes of the hanging version is also worth something.

Video instruction on the construction of a hanging category truss structure:

There are actually many more methods for constructing rafter systems for roofs with two slopes.

We have described only the basic varieties that are actually applicable for small country houses and buildings without architectural tricks. However, the information presented is enough to cope with the construction of a simple truss structure.