Helpful information

When the installation of a plastic window is carried out by specialists, it seems that there are no difficulties, everything happens quickly and accurately. The assemblers work like a perfectly tuned watch mechanism, where every part fits exactly into the right place. However, not everything is so simple and you need to know exactly what and how to fix it so that the window does not cause problems. It is important to select fasteners for correct installation, as well as direct installation of a specific structure.

Basic mounting elements

The variety of fastener elements can become a stumbling point for an ignorant person, but installers know exactly what parts may be needed during installation. The TBM-Market store offers a wide selection of fasteners for windows, because installation fasteners, if installed correctly, will significantly increase the service life of the structure.

Types of fastening elements:

- dowels or screws for concrete;

- frame anchors different types(anchor bolts);

- dowels and anchor plates;

- self-tapping screws different diameters, including nipples for them;

- various screws and so on.

The installers install the window and select the necessary fastening that suits the type of walls in your apartment. A good quality fastener, not intended for a specific structural material, will give a poor result, and the period of reliable operation will be shorter.

- Through installation of plastic windows:

- Mounts for concrete walls(pins)

- Frame anchors

Most installers prefer to use concrete dowels or screws (turbo screws), since the dowel is installed quickly, holds the weight of the glass unit reliably, and is firmly fixed in the material. When working, a hole is pre-drilled into which a screw with a threaded notch is screwed in without a dowel, which ensures the strength of the fastener.

The dowels have standard sizes for window openings– 7.5 by 152 (132), if it is necessary to replace the glass with light-protective, fire-resistant, etc., the structure is easy to dismantle.

Disadvantage of fastening: dowels cannot be used when installing plastic windows in non-uniform walls that have a layer of insulation.

The standard anchor has three components: a screw, a bushing and a conical nut; it requires drilling a hole for installation in the profile and in the wall. The bushing is at the same time a helping element for screwing in the screw, an additional locking link that ensures fixation of the screw in the hole. The countersunk head of the anchor (dowel) can be recessed into the hole or covered with a special cover.

Standard anchors for concrete (solid brick) have a length of at least 60 mm, for porous blocks or slotted bricks - at least 80 mm.

Dismantle plastic window on anchors it is more problematic than on screws, so you need to be especially careful during installation. The disadvantage of anchor dowels is that they cannot be used for multi-layer walls, especially when there is an insulating layer.

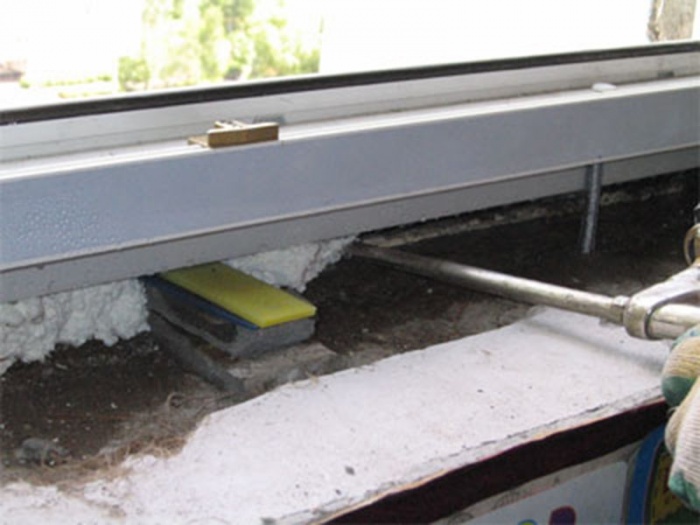

This type of fastening assumes that the integrity of the frame structure will not be compromised (holes are not drilled). For panel-type houses with walls of a multilayer structure, anchor plates are used for glazing loggias, attached to window opening, and polyurethane foam. The plate is attached at the end to the frame using self-tapping screws, and it is secured to the wall with dowels (length no more than 40mm).

If you or someone you know has previously used the services of companies installing double-glazed windows, then you know that installation can be normal and in accordance with GOST. The second option is more expensive, but if all the requirements are met, the quality will be much higher than in the first (you can read more about the standards in GOST 30971-02).

Consists of several stages.

Note! Manufacturers do not provide a guarantee if the measurements were not carried out by their employees. If installed incorrectly, the windows will soon begin to freeze, and if even the slightest mistake was made in the calculations, the structure simply will not fit into the opening.

However, if you study all the intricacies of the process, then no difficulties will arise during installation. Moreover, this way you can save a decent amount of money.

Video - Installation of PVC windows according to GOST

Stage 1. Measurements

In most apartments there are openings without a quarter.

Note! A quarter is an internal frame 6 cm wide (or ¼ brick, hence the name) that prevents the window from falling out and strengthens the structure as a whole.

If there is no quarter, then the frame will be installed on anchors, and the foam will be covered with special covers. Determining the presence of a quarter is quite simple: if the internal and external widths of the frame are different, then there is still a quarter.

- First, the width of the opening is determined (the distance between the slopes). It is recommended to remove the plaster for a more accurate result.

- Next, the height is measured (the distance between the slope above and the window sill).

Note! The measurements must be repeated several times and the lowest result taken.

To determine the width of the window, two installation gaps are subtracted from the width of the opening. To determine the height, the same two gaps plus the height of the profile for the stand are subtracted from the height of the opening.

The symmetry and straightness of the opening are checked, for which they are used mounting level and plumb line. All defects and irregularities must be indicated in the drawing.

To determine the width of the drainage, add 5 cm to the existing drainage for bending. Also, the width of the insulation and cladding is taken into account (subject to subsequent finishing of the facade).

The dimensions of the window sill are determined as follows: the width of the opening is added to the size of the overhang, and the width of the frame is subtracted from the resulting figure. Regarding the offset, it should cover the heating radiator by a third.

Note! measured after installation is complete.

Stage 2. Order

After measurements, the finished drawing should be taken to the window manufacturer, where all the details will be selected. necessary fittings. It is worth remembering that installation can be performed in one of two existing ways:

In the first option, you will have to pull the package out of the frame, insert it into the opening and install the glass back. In the second case, the entire structure is attached as a whole. Each option has disadvantages - if you pull out the package, it can; and vice versa, if the window is installed assembled, it can be damaged due to its heavy weight.

Prices for a popular line of windows

Stage 3. Preparation

This stage of installation begins only after delivery of the ordered windows. Released first workplace, all furniture is covered plastic film(there will be a lot of dust).

Step 1. If required, the glass unit is removed from the window. To do this, the glazing bead is slightly pryed with a staple and pulled out. First of all, the vertical beads are removed, then the horizontal ones. They must be numbered, otherwise gaps will form after installation.

Step 3. The bolts are unscrewed after the plugs are removed from the canopies. The handle is turned to the “ventilation mode” (in the center), the window is opened slightly and removed. All that remains is the frame with imposts.

Note! Imposts are special jumpers designed to separate the sashes.

Then you need to make a marking for the anchors and make holes along it - two on the bottom/top and three on each side. To do this, you will need ø1 cm anchors and a drill of the required diameter.

If the material from which the walls are made is not dense (for example, cellular concrete), then fastening is carried out using anchor suspensions. The latter should be fixed to the wall and frame with hardened self-tapping screws (eight pieces for each).

Note! To avoid the formation of a thermal bridge in the window sill profile, it should be filled the day before installation. This way the element will not freeze.

Stage 4. Dismantling work

This procedure is recommended to be carried out immediately before installing a new window. In most cases, the old ones are thrown away, so the structure can be torn out along with the fastening, and if necessary, the frame can be sawed.

Step 1. First, the seal and thermal insulation are removed.

Step 3. The window sill is removed and the cement layer underneath is cleaned off.

Step 4. Adjacent surfaces are treated with a primer material (by the way, many installers forget about this). In the case of a wooden opening, a layer of waterproofing material is laid around the perimeter.

Note! Installation can be carried out at a temperature not lower than -15ᵒC. Polyurethane foam must be frost-resistant.

Stage 5. Installation of a plastic window

Step 1. First, wooden wedges are placed around the entire perimeter, a window is installed on them (this will make it easier to level the structure), only after this is it fastened to the wall. You can leave the backings - they will serve as additional fasteners.

Step 2. The absence of a support profile can be considered a gross violation of GOST standards, since it is not only needed for stability, but also makes it possible to install a low sill with a window sill. In the absence of a profile, they are attached directly to the frame, which violates its tightness.

The correct location of the stand profile is shown in the diagram.

Step 3. Next, the evenness of the window is checked in three planes, for which a mounting level and plumb line are used. It is characteristic that traditional bubble levels are not suitable for this due to insufficient measurement accuracy, so it is better to use.

Step 4. If the window is level, then it is secured with anchors. To do this, a wall is drilled using a hammer drill through pre-prepared holes in the structure (approximately 6-10 cm). The lower anchors are fixed (not completely), the evenness of the package is checked again, after which the remaining points are attached.

Note! The final screed is made only after the final inspection. Do not tighten too much, otherwise the structure will “skew”.

Prices for mounting foams and cleaning gun cleaners

Polyurethane foams and cleaners for construction guns

Stage 6. Drainage

From the outside, the ebb is attached to the stand profile with self-tapping screws. The joints are carefully sealed with sealant to prevent moisture from penetrating into the structure.

The edges of the ebb are recessed several centimeters into the walls, having previously made indentations using a hammer drill.

Note! Before installation, the bottom gap is also sealed.

Stage 7. Window assembly

After attaching the anchors, the glass unit is inserted back.

Step 1. The glass is inserted and fixed with glazing beads (the latter should snap into place, for which you can lightly tap them with a rubber hammer).

Step 2. The doors are opened and their tightness is checked. IN open position arbitrary opening/closing of the sash cannot happen if the window is installed level.

Step 3. The assembly seam is sealed on the sides. Polyurethane foam will provide high-quality waterproofing and prevent glass fogging. Before and after sealing, the seams are sprayed with water to improve polymerization.

Note! The seams are filled to no more than 90%, otherwise the structure will “lead.” If everything is done correctly, after drying the foam will protrude out a few centimeters.

Step 4. The perimeter of the window is glued with a special vapor barrier tape, and a material with a foil surface is used below.

Stage 8. Installation of the window sill

Step 1. The window sill is cut so that it fits into the opening and at the same time rests against the lining profile. There remains a small gap (about 1 cm) for thermal expansion. Subsequently, the gap is hidden by plastic

Step 2. Wooden wedges are placed under the window sill. It needs to be laid with a slight slope towards the room, and then applied with something heavy until the foam dries. Additionally, the window sill can be fixed with anchor plates.

Video - Instructions for installing plastic windows

conclusions

Now you know how plastic windows are installed, so you can safely get to work. The final check of all elements can be carried out only 24 hours after completion of installation (then the foam will have already “set”).

The described technology is also quite applicable to, although it also has its own nuances - such as, for example, installing a parapet to create a partition.

Find out how to do it correctly from our new article.

Technology for installing plastic windows in brick house differs from the rules for installing PVC profile products in concrete or panel walls. It is important to understand these differences and avoid mistakes before starting installation work.

Installation of plastic windows requires a set of tools and consumables.

Plastic windows in a brick house can be installed on anchor plates or bolts. Their size depends on the depth of the quarters into which the product will be attached, as well as the quality of the brick from which the walls are laid. It can be gas silicate, foam concrete, etc.

//www.youtube.com/watch?v=PkRy0THGINA

If the installation is carried out in a secondary housing stock, before installing the window, you must first remove the old frame from the opening. To do this you will need:

- removing the sashes from their hinges;

- deleting the old one;

- dismantling the window sill and ebb;

- removal of roofing felt and tow, once used to insulate the opening;

- chipping old plaster if it is necessary to align the geometry of the opening.

To dismantle you will need a small crowbar. If the frames are quite massive, then to facilitate the breaking process you can use hand saw woodworking or jigsaw.

To drill holes for fasteners, you will need a hammer drill, and to attach the frame to anchors, you will need a screwdriver. You will also need a construction knife with replaceable blades, a level, good quality construction guns for foam and sealant.

What materials are needed to install a plastic window?

Installing plastic windows is a multi-stage process. At each stage it is necessary to use various consumables:

- mounting wedges;

- professional foam;

- PSUL or acrylic sealant;

- water vapor barrier tapes;

- anchor plates or bolts.

- cyacrine;

- sealant.

Mounting wedges are needed to level the level; if necessary, they are placed under the stand profile.

Polyurethane foam- insulating material for filling the installation seam, i.e.

space between the wall and window frame. Professional pistol foam must meet temperature conditions season in which it is planned to install a plastic window.

PSUL (pre-compressed self-expanding sealing tape) is glued along the perimeter of the window frame and expands from the street side of the seam - from the quarter edge of the frame. In appearance it resembles gray foam rubber. If there are no quarters, you will need a special acrylic sealant.

A waterproofing tape made of membrane material is placed under the flashing to provide ventilation and protect the bottom seam from moisture.

Sealant is necessary to fill the seams where the window sill joins the slopes and the window frame.

How to attach a window to an opening?

The rules for installing plastic windows are explained in detail by GOST R 52749-2007 “Window installation seams with vapor-permeable self-expanding tapes. Specifications" This state standard prescribes that before you begin installing a window in an opening, stick PSUL around its perimeter.

This self-expanding material is self-installation This is a layer that cannot be covered with plaster, putty or painted over. Otherwise, the insulating material will not perform its functions.

When inserting a frame into a window opening, you should adhere to the tolerances. The deviation of the window frame in the horizontal and vertical plane should be no more than 1.5 mm per 1 m of length, but no more than 3 mm over the entire height of the window.

//www.youtube.com/watch?v=J4zdj8hP5As

The frame is attached to brick wall By following rules:

- from internal corner the vertical distance between the frame and the first fastening element should not exceed 150-180 mm;

- from the impost to the horizontal fasteners, this distance is recommended to be 120-180 mm;

- vertical placement of anchors - with a gap of 700 mm for windows made of white plastic and 600 mm for laminated profiles.

The inserted block must be checked for deviation from the level and foamed around the perimeter.

Assembly seam construction

PSUL around the perimeter and foam insulation are only 2 parts of the three-layer filling of the installation seam described by GOST.

After foaming the frame, it is necessary to remove the installation mounting wedges from under the stand profile and fill the resulting voids with foam. For better adhesion, the inner surface of the window opening can be moistened with a spray before foaming.

Before installing the drip sill, a waterproofing, vapor-permeable tape should be applied to the outside. The ebb is screwed to the stand profile with self-tapping screws. The edges of the ebb should be folded onto the outer slopes to avoid moisture getting under it.

WITH inside A vapor barrier is glued around the perimeter of the window (except for the lower horizontal part of the frame), which provides an additional sealing layer to the installation seam and insulates it from moisture. This tape is available in various widths and can be applied both under wet finishing of slopes (plaster) and dry finishing (slopes made of polystyrene foam or plastic). Released and universal tapes downhill.

A vapor barrier is also installed under the window sill board: full-butyl tape with a foil layer.

Assembling the installed window

The frame installed in the opening and foamed around the perimeter must be assembled.

The frame installed in the opening and foamed around the perimeter must be assembled.

Double-glazed windows are inserted into blind, non-opening parts. To glaze (fasten) installed double glazed window, you will need a medium sized Plexiglas hammer. The beads are cut at an angle of 45° and inserted into the frame around the perimeter of the glass unit with some force. In order for the glazing bead to finally snap into place, it must be lightly knocked down with a hammer.

If installed window unit has opening doors, you need to hang them on hinges. This task is not difficult to cope with, since modern window fittings are very easy to use.

But putting the sash in place is not enough. You should check its functionality and, if necessary, adjust it in the hinge part using a special adjusting key.

To check how accurately a plastic window is level, you need to open the sash. If it does not slam shut or open wider by inertia, it means the block is installed correctly.

Installing the window sill and slopes

The installation of wooden windows, like plastic ones, cannot be considered complete if the window sill is not installed. The window sill board snaps into place and is attached to the stand profile.

If, during dismantling, voids are identified under the window, you can fill them with insulation, for example, rolled or tiled, and then install a window sill.

For final finishing opening, you need to understand how to properly install the slopes. They can be plastered or assembled from sandwich panels made of expanded polystyrene foam.

With the latter option, the panels are cut to size locally, taking into account the geometry of each slope. A U-shaped plastic profile, otherwise called a starting profile, is screwed to the frame close to the slopes. A panel is inserted into it. The voids foam.

Foam is a polyurethane foam sealant that, due to its properties, requires a certain amount of time to fully expand and harden. Typically from 1 to 24 hours.

Sandwich panels are closed where they meet the wall decorative profile, most often F-shaped.

The junctions of the slopes and the frame to the window sill are sealed with sealant.

Who should you trust to install the window?

Installing a PVC profile window and installing a wooden window are not the same thing. Installing windows in a brick house involves certain nuances. You need to have all the necessary tools on hand, including adjusting wrenches for window fittings, as well as a supply of fasteners and special mounting tapes.

It is equally important to choose the right mounting foam and sealant. As an alternative to the latter, you can use the so-called liquid plastic. This is a special adhesive-sealant that hardens very quickly, but also creates a particularly strong sealed seam.

If you are not sure that you can handle the installation yourself, it is better to seek the help of specialists.

//www.youtube.com/watch?v=qMBqdgWXysU

Plastic windows are increasingly being installed by owners country houses, since they have many advantages compared to wooden products. They are also reasonably priced. But before installation, you need to carefully prepare for such work. To do everything yourself, you need to know the specifics of performing all operations.

All plastic products are equipped with parts for installation, so with proper preparation, you can install the window without outside help. It is necessary to perform all actions very carefully so as not to damage the structure. In order to secure the windows in the opening more carefully, it is worth working with an assistant. In some cases, before carrying out work, it is necessary to strengthen the opening.

Materials required for work

Before you begin installation, you need to prepare the following materials:

- wedges inserted for correct location windows;

- polyurethane foam;

- sealant;

- water vapor barrier material necessary to protect joints from moisture;

- anchor bolts.

Wedges are used during the installation process for more precise installation plastic profile. Without these materials, it is much more difficult to monitor. Polyurethane foam is an insulating material that fills the space between the wall and the frame. When choosing foam, it must be taken into account that it must correspond to the temperature at which the work will be carried out. If you purchase material intended for use in summer time, its use in winter can lead to the creation of a poor-quality insulating layer.

You will also need self-expanding sealing tape during work. This material is glued around the perimeter of the window from the outside, after which it expands. Sealant is used to fill the space between the slopes and the window sill.

How to determine the correct position of a plastic window

Before carrying out installation work, it is important to correctly determine the position of the frame relative to the thickness of the wall. The plastic window should extend about a third inside from the street side. This rule is not mandatory, but when moving the window in any direction relative to the specified distance, it is worth considering that the length of the sills and window sills must correspond to the project.

It is important to consider the size of the radiator and its position. The window sill should not overlap it by more than ½ of the width. If you completely turn off the radiator, this can negatively affect the temperature in the room in winter, as well as the condition of the window. If installed incorrectly, plastic windows usually begin to fog up.

The length of the window sill should be approximately 15 cm longer than the window opening. Thanks to this, you can process the edges of the window sill while finishing the slopes. The window sill comes with side plugs, which should also be secured after installing the window.

Methods for fixing plastic windows

The choice of a specific fastening method depends on parameters such as the size of the window opening and the wall material. This should also be taken into account when choosing fasteners for plastic construction.

Plastic windows can be fixed in several ways:

- Using dowels or anchor bolts. They are fixed in pre-created holes in the wall.

- Plates with teeth that are located on the outside of the window profile. They are installed on a spacer and secured with self-tapping screws.

The first method described is considered more reliable. That is why large plastic structures are secured with dowels. The fastening that passes through the window block is more reliable and can withstand impacts.

If you decide to install a small plastic window, they can be secured using anchor plates. These fasteners can be hidden by slopes and finishing materials. But before carrying out work, small recesses should be prepared for them. This will avoid problems with plane alignment.

It is worth noting that when installing plastic windows, professionals combine the above methods. In this case, anchor bolts are used to secure the base of the profile and its vertical parts. The upper part is secured with plates.

Basic rules for installing plastic windows

To install windows correctly, you should follow several basic rules:

- Installation of plastic double-glazed windows should be done using polyurethane foam. This material allows you to give the structure additional rigidity. It also acts as a retainer and heat insulator.

- To protect the space between the window and the wall, it is necessary to secure a waterproofing material on the outside and a vapor barrier on the inside.

- Windows can be installed at any time of the year. Many professionals recommend carrying out work in winter, as this will allow you to immediately see whether mistakes have been made.

- Before purchasing foam, you must carefully study the features of the composition. Such materials differ in several respects. One of them is the solidification temperature. The instructions on the cylinder indicate the most favorable conditions for using foam. If they are ignored, the material may begin to deteriorate during the operation of the structure.

- When foaming the gaps between plastic windows and walls, it is necessary to fill in small portions. This allows you to use less foam.

- If the opening crumbles, it is necessary to clean the surface of old materials and strengthen it.

Following the described rules, you can install windows with my own hands without making mistakes that people who have no experience in such work make. The technology for installing plastic windows in a brick house is quite simple, but it is important to carefully perform each step so as not to make a mistake.

How the opening is prepared

Before performing window installation work, it is necessary to thoroughly clean the opening from dirt and dust. It is important to remove all remaining paint and building materials. Before installation, it is also important to compare the dimensions of the opening and plastic frame. If the gap is more than 4 cm, it is necessary to use not only foam. This is due to the fact that when using it, it will not be possible to create an even and high-quality seam. In addition, quite a lot of foam will be lost.

Before installation, you must remove the sashes from the frame. To do this, simply pull the pin out of the hinges. If it is necessary to remove a glass unit from the frame, remove the glazing beads holding the glass. These steps must be performed very carefully so as not to scratch the glass.

After removal, the sashes and double-glazed windows should be placed on a soft mat and leaned against the wall so that they are in a stable position. Double-glazed windows should not be laid flat, as this may lead to scratches on the surface of the glass.

After this the deletion occurs protective film and marking the places where the fastenings will be located. The distance between them should be about 40 cm. It is important to take into account that the distances from the corners should be more than 15 cm.

Installation process

After carrying out the described steps, spacers should be inserted into the window opening in the brick wall to create the necessary gap. The frame must be leveled using building level. It is also important to control side clearances.

In the openings of brick houses, it is necessary to mark the installation locations of anchors. After this, holes are created in the walls. If fastening is done using anchor plates, it is necessary to bend them so that they fit well on the wall.

On next stage The frame is being installed. It is important to check the horizontal and vertical structure of the structure before. How will it be finally fixed? After this, the bolts are finally tightened until the head protrudes above the surface by no more than 1 mm.

After all the described work, the sashes and double-glazed windows are installed, as well as the functionality of the entire structure is checked. If you installed the products with your own hands for the first time, you should carefully inspect the opening and make sure that no mistakes were made during the work.

Installation of slopes

Before installing external slopes, it is necessary to measure the width and length of the opening. Cutting plastic slopes is done using a circular saw.

Important! Slopes should only be secured to clean and level surfaces.

At the first stage, the upper horizontal part is secured. It needs to be recessed as deep as possible and the space needs to be filled polyurethane foam. Worth remembering. That it should not be released too much, since when hardening the material can change the shape of plastic products.

After this, the installation of vertical slopes occurs. During this work, it is important to check the verticality of the elements. The installation of the lower slope occurs in the same way. It is important to ensure that all elements are correctly joined and there are no gaps between them. Corners between plastic slopes are closed with a special part.

Installation internal slopes should be done only after careful preparation surfaces. If the opening crumbles, it is better to clean it up to the main wall and only then carry out further work. After this, the opening is leveled and filled with insulation. If necessary, the window opening is strengthened.

Today, owners of houses and apartments are massively replacing old wooden windows with practical and durable PVC structures. And this choice is quite justified for a number of reasons:

- Due to increased thermal insulation, material costs for heating are significantly reduced.

- High functionality and modern materials allow you to refuse additional work window maintenance: tinting the frames to give them an aesthetic appearance; caulking cracks to insulate windows for the winter; removing the insulation from the window in the spring; pulling gauze over the sashes to protect against mosquitoes and other midges and other work that is implied in the operation of wooden window structures.

- A sealed double-glazed window well insulates the room from noise, allowing you to preserve home comfort and protecting the peace of the owners.

- The structures have a long service life while maintaining impeccable functionality and aesthetic appearance.

- The cost of a plastic window is lower than a similar wooden product. For example, the price of unpainted double wooden frame without glass measuring 120x90 cm - 3600 rubles, and a plastic window - 5500 rubles. However, a wooden window will still need to be glassed and painted, and this additional expenses time and materials. Whereas the plastic window is already ready for installation.

Those who are going to take on the task of installing plastic windows with their own hands often lack basic knowledge of how to do it correctly. That’s why we present this article here in the form of instructions to help owners who want to carry out the installation themselves.

Installing plastic windows has a number of nuances. For example, PVC windows are not such universal designs. And their use has a number of limitations. Thus, it is not recommended to use plastic windows in cold rooms without heating (verandas, canopies, attics, garages, bathhouses, etc.). By the way, window production and installation companies prefer not to talk about this. In addition, there may be problems during installation window profiles PVC in multi-storey buildings above the 4th floor.

When choosing a contractor to replace windows in your house, you may encounter the fact that the craftsmen simply will not delve into the intricacies of this issue. There are only a few people who have control over the situation and can comprehensively cover it.

First, let's try to figure out the question: does it even make sense to install PVC windows with your own hands? Contrary to popular belief, installing windows is not that difficult. To perform it, you do not need to stock up on professional equipment or gain special experience over a long period of time. The installation procedure itself consists of two stages:

- dismantling the old structure;

- installation of a new plastic window.

Usually dismantling takes from 0.5 to 1.5 hours. The actual installation of the window (we take an average window measuring 2x2 m) will take another couple of hours. It turns out that it will take a maximum of three and a half hours to replace one window. Therefore, during Saturday-Sunday you can freely change at least 2 windows without resorting to the help of specialists. Considering that installers charge $40-60 for installing each window, we get quite a good saving. Some companies set installation costs as a percentage of the cost of the windows. This amount varies among different specialists and is about 10-40% of the price that is proposed to be paid for the windows. Also, when ordering windows from specialized companies, they can deliver the new structure to your home and dismantle it free of charge.

When entrusting the installation of windows to specialists, you can demand the following guarantees:

- When purchasing windows from a third-party company, installers provide a guarantee only for assembly seams and their filling, correct geometry of individual elements and functionality window design within 1 year after the work has been completed. Since self-installation practically deprives you of the warranty on window structures, you need to be more careful in choosing products. It is better to prefer windows manufactured at the factory, in compliance with all technical requirements and conditions. Handicraft products are a “pig in a poke”, the quality and functionality of which can present an unpleasant surprise. In this regard, to purchase window structures, it is advisable to contact directly manufacturing company, operating on the market for a long time and having good feedback from numerous clients. By the way, if you order windows in winter or spring period(i.e. out of season), you can get a significant discount;

- purchasing windows from a company that sells installation work, the customer receives a warranty on the fittings - from one to 5 years (the more expensive the windows, the longer the warranty period, as a rule);

- If the windows are installed with your own hands, then a warranty on the fittings must be requested at the place where the structures were purchased. You will have to take full responsibility for the quality of the seams.

Installation PVC windows You should do it yourself if you have:

- a couple of free days (weekends as an option);

- hard work and desire to learn something new;

- desire to save money.

If all of the above is present, then the recommendations outlined in this article will allow you to successfully replace the windows in your house, doing it no worse than a professional installation team. Actually, a whole team is not required to install the window; two people will be enough, one of whom will carry out the installation, and the other will hold the structure and serve necessary tools. Despite the apparent complexity, self-installation of PVC windows is a fairly simple process, representing a combination of several simple operations performed in a given sequence. Before you begin installation, you need to order a window, and this requires correct preliminary measurements. So…

Window measurements: everything you need to know

First, we determine the type of window opening.

It can be of two types: either with a quarter or without a quarter.

Taking measurements of a window without a quarter

A clean window opening is the easiest to measure. Such an opening is found only in a new house. We measure the opening itself in the vertical plane and subtract 5 centimeters from the resulting figure. We have height. Of these 5 centimeters, 1.5 centimeters will be filled with mounting foam at the top of the window, and 3.5 centimeters will be laid for installing the window sill. Similarly, we measure the opening in horizontal plane, subtract 3 centimeters for the gaps (1.5 cm on the right and left) and get the width of the window.

Next, measure the length and width of the ebb and window sill. To the resulting dimensions you need to add from 5 to 20 centimeters in order to “embed” the window sill a little into the wall on both sides. If you are getting down to business for the first time, then set the size of the window sill larger - during installation, all excess will be cut off. As a rule, window sills and ebbs have a standardized width (10-60 cm) and length (up to six meters). Having minimum dimensions, installers will be able to select and deliver the most suitable parts.

We take measurements of the window and a quarter

Width: measure the opening in the horizontal plane between the quarters and add three centimeters to the resulting figure (one and a half centimeters on each side). Height: measure the distance from the bottom edge of the opening to the edge of the top quarter. There is no need to add or subtract anything from the resulting figure.

The window sill and ebb are measured, as in the first option.

As a result, after all the measurements made, we should have written down:

- window height and width;

- length and width of the ebb;

- length and width of the window sill.

When replacing old windows, the previous structure is located in the opening, which means that the opening itself cannot be measured. Therefore, it is necessary to take measurements from the window frame, which will subsequently be dismantled.

When ordering a window, try to find out what comes with the windows. Typically the following elements are included:

- windowsill;

- end caps. To choose the right plugs, you need to indicate the width of the window sill (the protruding part from the wall);

- installation profile;

- anchor plates – structural fastening elements.

If these parts are not included in the kit, you will have to purchase them additionally.

In addition to dimensions, other data may be required:

- profile type (number of cameras);

- double-glazed window option (number of glasses and air chambers);

- type of opening window sashes. The most common: swing, tilt and turn with ventilation, combined. In addition, in some cases, blind windows are installed that cannot be opened. The type of opening is determined by the fittings installed in the structure. The ease of use, functionality and durability of the window depend on the type and quality of the fittings. There are several types of window openings. For convenient ventilation, the window should be equipped with tilt-and-turn fittings. Blind versions of the sashes are unsuitable for ventilation; conventional hinged sashes without turning are inconvenient.

Thermal conductivity and sound insulation of the window: so that noise and cold do not sneak into the house

Thermal conductivity of plastic windows

In addition to the manufacturer, when choosing a window, it is also necessary to take into account such quality as the thermal conductivity of the structure. According to SNiPs and territorial building regulations The window's heat transfer resistance coefficient varies depending on the climatic conditions of the region of residence. Structures that are installed in residential premises should not have a heat transfer resistance lower than that specified for the specific region of residence.

Thermal conductivity directly depends on the design and type of glass used in the double-glazed window. If you order windows with energy-saving glass, the thermal insulation of structures increases by 10-15%. The cost of energy-saving glass is about 250 rubles. for 1 sq. m.

The thermal conductivity of a window may decrease due to poor-quality installation, or less often due to manufacturing defects. Very often, in the process of improper installation, a chip or crack appears on a double-glazed window, and the structure loses one of its main qualities - tightness. Visually this manifests itself as fogging inner surface glass As a result, in winter the room will become colder, and the house will have to be heated more.

To improve the thermal conductivity parameters of the window, you can prepare a support profile. From the point of view of thermal conductivity, the stand profile is the weakest point in the window structure. To attach the drain, you will have to drill it, which will further worsen the thermal conductivity parameters. To normalize the thermal insulation properties of the window, the internal volume of the stand profile can be filled with polyurethane foam. This should be done the day before installing the window so that the foam completely hardens. Foaming of the stand profile is not provided for by GOST; window companies also do not practice this operation.

Soundproofing properties of plastic windows

This parameter is essential if there is a busy highway near the house or Railway. However, it is always more pleasant if external noise from the street does not penetrate inside the house. And this cannot be achieved without high-quality sound insulation window.

Methods for installing PVC windows: to unpack or not to unpack – that is the question!

When installing windows, you need to choose the type of installation - with unpacking (unpacking) or without unpacking. Want to understand how these two methods differ from each other? Take a look at the diagram of a plastic window.

- Frame– one of the main elements of the window. The frame is formed from a reinforced PVC profile and several sealed chambers. The number of cameras can vary from two or more.

- Double-glazed window- the largest element of the window, occupies about 80% of its area. It is a sealed structure consisting of glass. Depending on the number of glasses and air gaps between them can be single-chamber, double-chamber, etc. The double-glazed window fits tightly to the frame due to the seal.

- Glazing beads– parts that allow you to mechanically secure the glass unit to the frame.

- Impost– a divider, thanks to which the window is divided into several sashes. There are single-leaf, double-leaf, three-leaf, etc. designs.

- Blind sash– a sash without an opening mechanism.

- Transom- opening door.

- Window sill(other names – bottom, mounting, stand) profile – load-bearing element window design. It is necessary for correct installation and indoor fastenings plastic window sill and external drain.

- Accessories– all moving parts of the structure intended for opening, closing, fixing the transom when ventilating the room.

Window installation method with unpacking

(in some regions the term “unpacking” is used, the essence is the same). This method is based on preliminary disassembly of the structure: glazing beads and double-glazed windows. After fixing the frame to the wall throughly, all removed elements are installed again.

To quickly and correctly unpack the structure, you need a strong knife or chisel. We insert a knife blade or chisel between the glazing bead and the frame, and with gentle blows on the handle, knock the glazing bead out of the groove until a gap appears. Then we bend the knife (chisel) and push the elements apart with the wide side. We consistently do this with all the glazing beads that hold the glass unit in the sash. It is not recommended to do this procedure with the sharp end of a knife, since it increases the risk of damaging the window or glazing bead. To remove the glass unit, be sure to wear gloves, otherwise you will injure your hands on the sharp corners of the structure. If the window is not solid and there are sashes, remove them. If there is a transom in one of the sashes, it is easier to remove the entire assembly without removing the glass unit. That's it, the structure is ready for installation.

Disadvantages of the method: more labor-intensive, takes longer than installation without unpacking (on average, 30-60 minutes are added for each window). Often, fogging of the glass unit occurs in a window installed using this method. In addition, the appearance of the glazing beads may be damaged (scratches, chips) if they are removed/installed carelessly. It is important to perform all actions clearly and carefully. After removing the packages, you need to put them in a safe place where there is no chance of accidentally touching them and breaking them.

Advantages and scope of application of the method: installation of windows with unpacking is more reliable and provides a strong fixation of the frame to the wall. This method should be chosen in the following cases:

— it is planned to fasten windows in multi-story buildings (from the 15th floor). When installing windows on the lower floors, where there is no wind and gusts of wind, they do not need to be unpacked;

— installation of structures of considerable size is to be done. However, in this case, combined installation is allowed ( balcony block attaches without unpacking).

Window installation method without unpacking

This method does not require disassembling the structure. That is, there is no need to remove double-glazed windows and glazing beads. The frame is secured to the wall not with dowels, but with fasteners pre-installed on the outside of the wall.

Advantages and scope of application of the method: Installing windows without unpacking saves time, shortening the process as much as possible. This method is recommended for use where there is no need for increased fastening strength: when replacing standard windows in private houses, and also, as mentioned earlier, in multi-storey buildings below the 15th floor.

Installation of windows with and without unpacking: sequence, features, advice from professionals

The installation of plastic windows is specific, so this work requires a special set of tools and materials, without which it is almost impossible to install windows correctly and accurately. If you can’t buy the things you need in a specialized store, you can contact a window company - the professionals will definitely find what you’re missing.

- plumb and level

- screwdriver and hammer drill

- drill with a set of drills

- gun and mounting foam;

- hacksaw or jigsaw

- small crowbar or pry bar

- silicone gun

- chisel or knife with a wide blade

- mounting wedges

- tape measure and pencil

- roll moisture-proofing material

- sheets of iron (galvanized) and metal scissors (required for self-made drains)

The main stages of installing PVC windows:

- dismantling the previous structure and window sill;

- preparing a new window for installation;

- marking the frame for subsequent fastening;

- fixing fasteners to the frame;

- making holes for fasteners;

- leveling the plastic structure;

- securing the structure in the opening;

- installation of low tide (can be done at the end of the process);

- intermediate adjustment of fittings;

- foaming the cavities between the window opening and the frame;

- window sill installation;

- final adjustment of fittings.

Each stage of installing a plastic window should be considered separately.

Dismantling old window structures

Preliminary stage: preparing the window for installation

Windows with movable sashes are mounted in closed. When installing a window in open form there is a risk of deformation of the structure (the foam that will fill the gap between the opening and the frame can bend the frame). After foaming, the window is left for 12 hours, during which it cannot be opened. And to avoid accidental opening of the sash, you can postpone the installation of the handle until the installation of the window is completed.

It is not recommended to remove the tape that covers the surface of the window to protect it from damage until the installation of the structure and finishing of the slopes are completed.

PVC window installation sequence

Marking on the frame for fastening points

We retreat 5-15 centimeters from the corner of the frame and mark a place for the outermost fixing element. The frame needs to be fastened on 4 sides, the fasteners are located every 70-100 cm. If a stand profile is used, the frame is not fastened from below.

Fixing the fastener to the frame

Fastening elements include self-tapping screws, anchor plates, and U-shaped hangers for drywall.

Anchor plates and hangers have the same price - $0.05 (wholesale), $0.15 (retail). However, anchor plates are thicker than hangers. When purchasing, give preference to products made from thicker metal.

The fastener must fit tightly into metal frame frames In order for the element to secure well, the screws must be used for metal. Such products have a drill at the end and a diameter of 4 mm. You can also use simple self-tapping screws, only in this case you need to first mark the holes in the frame with a drill.

Applying recesses for fasteners

We place the frame with the fasteners attached to it in the window opening, then knock out recesses in the opening in the appropriate places (depth 2 - 4 cm, width similar to the size of the fasteners). The fasteners will later sink into these recesses. By completing this procedure, we will make it easier for ourselves to finish the slopes.

Advice: when installing a window without a mounting strip, you should place blocks of wood or other material underneath it. dense material so that it rises to the height of the window sill. Then it will be possible to attach the window sill not to window frame, and under it. If there is a mounting plate, the frame will automatically sit on the desired height. Typically, the mounting strip is already fixed to the frame and does not require additional fixation.

Leveling the window structure

This stage is the longest in the entire window installation procedure. However, by aligning the window in the vertical and horizontal planes, we automatically give it the correct rectangular shape. To level the structure, you need wooden wedges or bars that are placed under the frame. The first pair of lower wedges is set, then you can immediately fix the window from above with an anchor plate. Next we place two wedges at the top, then on the left and right at the bottom and top of the window. If there is an impost, you also need to put a wedge under it. During these steps, it is important to ensure that vertical racks did not deviate to another plane. It is convenient to level the window with two people, when one supports the structure, the second inserts wedges.

Attaching the window to the opening

Having achieved a perfectly level position of the window, i.e. Having set it correctly in level, we can proceed to fastening the structure. To do this, use dowels (diameter 6-8 mm, length 75-80 mm) or anchors (diameter 6-8 mm). The latter have a higher cost, but provide more reliable fixation. They are recommended to be used if the wall consists of shell rock, brick or foam concrete. Fastening on anchor plates is used if the block structure contains a thermal insert and the frame in the mounting plane cannot be mechanically secured. A dowel driven into concrete can withstand a load of up to 60 kg, which is quite enough to fix a window. For wooden walls, you can use screws with a diameter of eight millimeters.

Advice: do not immediately tighten the screws on the sides of the frame completely, leave 1 cm until they stop. There is no need to screw in the construction screws in the upper part of the structure yet. The frame will not go anywhere, and you will have the opportunity to check the uniformity of the gaps on the sides and, if necessary, move the frame in one direction or another. After the final fastening, this will be more difficult. If the uniformity of the gaps is satisfactory, the horizontal/vertical structure is maintained, you can completely fix the frame by screwing in the screws on top and tightening the remaining screws on the sides. After this, it is worth checking the horizontal and vertical structure again.

Fastening the ebb of a plastic window

Installation of ebb tides can be done at the very end. You can buy the ebb ready-made or make it yourself. It is best to secure this element under the window - this will prevent the penetration of water where it connects to the frame. Upon completion of the installation of the drain, the space between it and the profile is filled with foam. If it is not possible to attach the ebb under the frame, it is fixed directly to it, for which 9 mm metal screws are used.

Intermediate adjustment of fittings

It is necessary to tighten or loosen the window hinges so that the sash moves silently and freely when opening and closing. An open sash should not slam shut on its own. Correctly adjusted hinges will allow it to remain in the desired position.

When moving, does the sash “strike” where the locking hardware is installed? Move this element a little lower or higher.

Foaming the gaps between the opening and the frame

It is important to fill the gaps so that there are no voids left. Large gaps(more than two centimeters) are foamed in several stages, with a break between them of two hours. With this approach, there is no danger that the foam will deform the window as it expands. In addition, the consumption of polyurethane foam is saved, there is no excess that has to be cut off, and the quality of the assembly seam improves.

Since the foam hardens under the influence of atmospheric moisture, a lack of humidity in the room can lead to poor-quality polymerization. To avoid this, you need to lightly spray the area between the window opening and the frame with water before foaming, and after filling the cavity, spray the surface of the foam itself with water. If the air temperature during installation does not exceed five degrees, then winter or all-season foam is used. In warmer weather, you can use summer foam.

After polymerization of the foam, it is necessary to protect it from exposure to ultraviolet radiation. This stage can be combined with finishing the slope. But if you don’t want to make slopes yet, or plan to do it later, then the foam needs to be covered immediately, since it quickly collapses due to exposure to direct sunlight. In this case, we prepare cement-sand mortar at the rate of 1 part cement and 2 parts sand, or dilute tile adhesive and cover the foam with any of these materials. In addition, you can purchase at hardware store PSUL tape (vapor-permeable self-expanding sealing tape) and cover the mounting foam with it. However, the cost of the tape is quite high (from $3 per linear meter), so the first options are used more often.

Window sill installation

1. Trimming. The window sills have a standard length and width and have a good margin, both in length and width. Before installation, the window sill is cut using a jigsaw, grinder or saw with small teeth.

2. Leveling. We move the window sill to the stand profile and level it using wooden blocks or other available materials.

We cover the side sections of the window sill with end caps. It is better to glue the plugs to the ends with super glue.

By lightly pressing the window sill with your hand, we make sure that it does not sag. In some cases, the window sill is not installed level, but under small angle(no more than 3 degrees) “from the window”. Thanks to this slope, possible condensation does not flow under the window.

We foam the cavity under the window sill.

After foaming, place something heavy on the surface of the window sill (you can use plastic bottles with water, books) and leave in this form for 0.5 days.

If you do not press down the window sill with a load, it will bend upward under the influence of foam.

3. One day is enough for the foam to completely harden. After which its remains, sticking out unsightly from the crack under the window sill, need to be cut off using a utility knife.

4. If the window sill initially had unevenness, then during installation there may be a gap between it top part and frame. It is carefully filled with silicone. It is worth considering that this material has low biostability and can turn black from fungus. A gap will not appear if galvanized iron plates in the shape of the letter “Z” are fastened to the window sill profile in advance (before installation). In addition to the fact that these plates will allow you to grind the window sill tightly, they will simplify the task of leveling it.

Final window adjustment

At this stage, you can remove the protective tape from the window structure and finally screw on the handle. If finishing the slopes is postponed, do not remove the tape until all finishing work is completed.

Possible errors when installing windows

Here we list the mistakes that are often made when installing windows and can negatively affect the ease of use and service life of the structure:

- Installation is carried out with glazing beads facing outwards. This reduces the window's burglary resistance, since in this case the beads can be easily removed from the outside and the glass unit can be pulled out.

- The window is poorly aligned, making it difficult to open and close.

- The polyurethane foam is not protected from the sun's rays, as a result of which it is destroyed.

- Due to incorrect measurements or too low fastening of the window structure, the window sill cannot be placed under the frame and must be attached directly to it.

- The window structure is not fixed by any fasteners and is held in place only by polyurethane foam. Then cracks may appear on the slopes, since foaming is not a full-fledged fastening. Over time, it loses strength and the window becomes so mobile that it can fall out.

We hope that after reading the article you will be able to successfully cope with the installation of PVC windows. And even if you decide to contact installation organization, you will be able to understand and control this process at all stages.