Can't connect to the central sewer? You can solve the problem locally - install a septic tank. To make this task easier, we have prepared a review of 9 reliable septic tank manufacturers. There is a good chance that other companies you come across are either copying or counterfeiting these 9 products.

We warn you! Hereinafter, by septic tanks we mean any engineering structures, intended for the collection or processing of wastewater, unless otherwise indicated. These include VOCs and SBOs – local treatment facilities and biological treatment plants, respectively.

Instructions for selection and installation of VOCs

Purpose of the article: talk about the most reliable companies that have been producing septic tanks and biological treatment plants for household wastewater for more than 10 years. Simplify the selection of the appropriate equipment model based on the needs of the buyer, soil conditions on the site and the purchase budget.

Types of septic tanks

Before we talk about sewage treatment plants, let's do a little education. Conventionally, all treatment facilities can be divided into 3 groups:

- storage tanks. It doesn’t matter what they are made of, their function is the same - to accumulate waste until the sewer truck arrives. Relatively cheap, easy to install, and do not require maintenance as such. Use is limited by the useful volume of the container, hence the need to use water economically and rely on the services of vacuum cleaners. It's inconvenient and expensive. They are used only when soil and other conditions do not allow the installation of structures from the following two groups;

- settling tanks. Multi-section tanks that do not require an electrical connection for settling wastewater and its anaerobic treatment. Microbiological purification processes proceed slowly in an oxygen-depleted environment. The outlet water has a characteristic odor and is purified to a maximum of 60%, so it must be further purified. For this purpose, fields or filtration wells are used: wastewater seeps through the soil layer, after which it does not pose a threat to the environment. Sedimentation tanks are simply designed and affordable, but require maintenance. They need to be periodically cleaned of accumulated sediment, and the filtration field needs to be redone every 5 years. This solution is not suitable for high level groundwater (GWL) and soil with poor throughput, for example, clay;

- aeration stations. The most advanced systems for preparing household goods. drains. Through the process of settling, aeration and the use of microorganisms, the wastewater is purified by more than 90%, has no odor, and can be discharged into roadside ditches. However, such stations require connection to the power grid, and their efficiency suffers during power outages. Plus, they are expensive and require qualified maintenance.

We've sorted out the types of treatment facilities. It remains to take 5 steps to choose the one that suits your operating conditions.

| Step 1. Select your accommodation option | |

|---|---|

| seasonal (at the dacha) Terms of Use:

|

Ideal for:

|

| permanent (in a private house) Terms of Use:

|

Ideal for:

|

| Step 2. Select the type of soil on the site | |

| clay Initial conditions:

|

Ideal for:

|

| sand, sandy loam, loam Initial conditions:

|

Ideal for:

|

| peat Initial conditions:

|

Ideal for:

|

| Step 3: Select Groundwater Depth | |

| above 1.5 Initial conditions:

|

Ideal for:

|

| below 1.5 Initial conditions:

|

Ideal for:

|

| Step 4. Select a model based on battery life | |

non-volatile

|

Ideal for:

|

volatile

|

Ideal for:

|

| Step 5. Select the number of permanent residents | |

up to 5

|

Ideal for:

|

to 10

|

Ideal for:

|

up to 20

|

Ideal for:

|

We hope that this table helped you choose the appropriate septic tank option. All that remains is to decide on the manufacturer. The table below contains 9 companies and their a brief description of. All the manufacturers we reviewed offer solutions for both seasonal and permanent residence.

| Manufacturers of all types of septic tanks | ||

|---|---|---|

| , all types of septic tanks Bars |

Ideal for: residents of the above cities, because Bars is a practical and economical option waste disposal. You can choose the most suitable model for the specific operating conditions of the septic tank. |

Middle price segment:

|

| , models Topas, TopBio, TopAero |

Ideal for: permanently residing in a private house, provided there are no interruptions in power supply. |

Middle price segment:

|

| , models Kedr, Unilos Astra, etc. |

Ideal for: VOC devices in a house with permanent residence. |

Middle price segment:

|

| , models Microbe, Tank, Biotank |

Ideal for: budget purchase for the dacha, which is facilitated by frequent manufacturer discounts and the simplicity of the design of most models. |

Budget price segment:

|

| , Termite and Ergobox models |

Ideal for: residents of the cities indicated above due to free shipping. For those who are looking for an alternative to Tank structures. |

Budget price segment:

|

| , Eurolos models |

Ideal for: those who need simple models septic tanks for cottages at a low price. |

Budget price segment:

|

| Manufacturers of non-volatile septic tanks | ||

| , Rostock models |

Ideal for: devices for inexpensive autonomous sewerage in the country. |

Budget price segment:

|

| Manufacturers of local treatment facilities | ||

| , models Eurobion, Yubas |

Ideal for: permanent residence, when the maximum degree of wastewater treatment is required, even with significant volley discharges. |

Premium price segment:

|

| , models Tver |

Ideal for: large areas for permanent residence, because hatches provide free access to all parts of the installation and take up a lot of space. |

Middle price segment:

|

1. “Aqua Hold” – septic tanks Bars

at a price of 54,900 rub.

2. “Topol-ECO” – Topas treatment facilities

at a price of 89,900 rub.

Topol-ECO is engaged in the development and production of autonomous aeration-type treatment plants. The company was founded in 2002, the plant is located in the Moscow region, Lobnya.

The manufacturer's catalog includes both individual treatment facilities for private homes, as well as complex and specialized solutions for a group of houses, towns and enterprises. There are also other plastic products: cellars, decorative stones, contact tanks, galvanic baths, etc.

The company produces VOCs, which comprise 3 large groups:

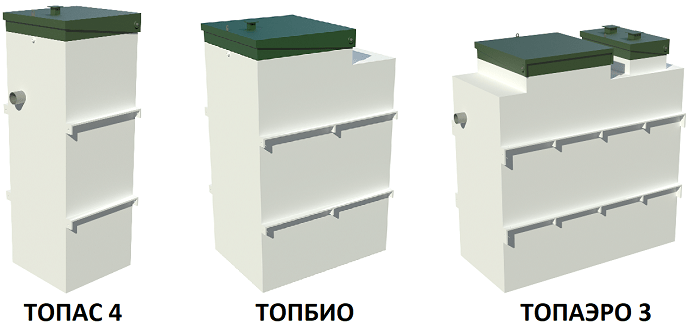

- For private houses. Topbio – non-volatile septic tanks for installation in sandy soils. Topas and Topas-S are stations with two or one compressor, respectively. Topaero - treatment facilities with protection against increased volley discharge of wastewater.

- For enterprises and towns. Topglobal is a complex of equipment with reinforced concrete tanks for cleaning household goods. and industrial wastes. Topaero-M is a set of VOCs with increased total productivity for the treatment of domestic wastewater. Topaero-M/E is an analogue of the previous version for any type of waste.

- Specialized stations. Toplos-FL – for cleaning wastewater from organic matter. Cyclone is a system for post-treatment of household wastewater. Toplos-KM – container-type VOC for household use. drains. Toppolium – fat separator from industrial wastewater Catering. Toprein is a stormwater treatment plant.

The equipment presented covers wide range in terms of performance. The youngest models are designed for 4 people, the oldest – up to 200. The use of active forced aeration guarantees the purification of household waste by 98%. Therefore, the company positions its sewage treatment facilities as treatment facilities that do not require calling a sewer truck.

In most cases, polypropylene sheets with a thickness of 8 to 20 mm are used as the main material. The rigidity of the structure is achieved by using internal partitions and lattice structures as stiffeners.

| Model* | Topas 4 | Topbio | Topaero 3 |

|---|---|---|---|

| terms of Use | For permanent use by a family of up to 4 people on a plot with any ground level and type of soil. | For permanent or seasonal use by a family of 3-6 people on a site with sandy soil and low groundwater level. | Permanent use for large families and guests – up to 15 people in total. Any ground conditions. |

| Short description | System with two compressors for wastewater aeration and deep biological treatment. Effluent can be disposed of in the ground or in a ditch. | A vertical 5-chamber non-volatile septic tank for which a filtration field is required. | Aeration system designed for volley discharge of wastewater up to 1 m3. Wastewater with up to 98% purification is odorless and can be disposed of in a ditch. |

| Material | Polypropylene 12.5 mm for external walls, internal partitions 8 mm thick. | ||

| Size, L×W×H, mm | 950×970×2500 | 1600×1200×3000 | 2400×1200×2500 |

| Electricity consumption, W/h | 42-63 | — | 208 |

| Weight, kg | 215 | 400 | 605 |

| price, rub. | 89900 | 115900 | 218700 |

* you can select a modification with a built-in pump for forced pumping of treated wastewater. Models with higher productivity come with an extended neck for in-depth installation of the station when it is located far from home, as well as reinforced versions for difficult soils.

Conclusion: The main part of the products from Topol-Eco, which can be used in a private home or on a summer cottage, are energy-dependent biological treatment stations. They are made using the most advanced technology to date, which is why they are more expensive than conventional septic tanks with a filtration field. But you also need to take into account that such equipment requires qualified maintenance, does not tolerate long-term power outages and is designed for constant use.

3. “SBM-Group” – Unilos treatment facilities

at a price of 59,000 rub.

The SBM-Group company produces Unilos stations, storm sewer, KNS, plastic containers, fat separators. The plant has been operating since 2006 in the Moscow region, there is production in St. Petersburg, Novosibirsk, and a plant was opened in Kazakhstan in 2015.

Production technologies and range

The main emphasis is on autonomous sewage systems made of polypropylene, fiberglass and concrete. The stations are designed for cleaning household goods. and storm water. The productivity of septic tanks, depending on the chosen model, can range from 0.6 to 10,000 cubic meters per day.

Septic tanks are represented by three product lines:

- Biological treatment stations Unilos. This includes models of the Astra series and a modification with a service platform - Scarab, high-performance systems for villages - Mega, container-type kits for rotational camps - Container.

- Low-capacity septic tanks for summer cottages. The line includes aeration stations of the Uni-Sep series of hybrid type, a four-chamber non-volatile wastewater purifier Kedr and a three-chamber Unilos-OS.

- Storage containers. Containers made of polypropylene and reinforced fiberglass with pumping of wastewater using a sewer machine.

| Model | Unilos Astra 5* | Uni-Sep-1 | Cedar |

|---|---|---|---|

| terms of Use | For a family of up to 5 people on a plot with any ground conditions. | For permanent or seasonal residence of 5 people in conditions of periodic power outages. For any soil. | |

| Short description | Vertical station for deep biological treatment of household goods. drains with gravity or forced drainage. Treated wastewater is discharged into a ditch or ground. | Horizontal VOC with 2 service hatches and 6 chambers for anaerobic and aerobic wastewater treatment. Discharge of purified water into a ditch or filter well. | Vertical non-volatile septic tank with 4 chambers for cleaning household wastewater. Mandatory installation of a filter field. |

| Material | Polypropylene. The side walls are 15 mm thick, the bottom is 20 mm thick. | Polypropylene 8 mm thick. | |

| Size, L×W×H or D×L, mm | 1030×1120×2000 | 1020×2000 | 1400×3000 |

| Electricity consumption, W/h | 60 | 71 | — |

| Weight, kg | 220 | 130 | 150 |

| price, rub. | 89500 | 72000 | 62400 |

*this is standard equipment. There are Midi modifications with a built-in pumping station, a post-treatment and/or disinfection unit, as well as Long - with the same options, only of greater height.

Unilos Astra 5 is the most popular model among those who live in a private home all year round. The video below talks about the design of such a station and describes in detail the principle of its operation.

Conclusions: From the SBM-Group company under the Unilos brand you can choose the Astra aeration system, which is very similar in design to Topas from Topol-Eco. The choice among non-volatile septic tanks is limited to one model, but you can choose a storage tank of the required volume. Those. The manufacturer is more focused on consumers who permanently live in their own home.

4. “Elite Stroy Invest” – Tank septic tanks

at a price of RUB 34,900.

The Elite Stroy Invest company (formerly Triton Plastic) specializes in the production of plastic septic tanks, water and fuel tanks, caissons, swimming pools and a variety of goods for the garden. The plant is located in the Moscow region, Mytishchi. Operating since 2007. Deliveries are possible throughout the country through the dealer network.

Production technologies and range

The catalog includes products for drainage devices of three types:

- storage containers. This includes containers made of Triton-N polyethylene with a volume of 1 to 3.5 m3;

- septic tanks And. This includes the Microbe model (3-12 people) - a 2-chamber model for a summer residence, as well as Triton-T (2-10 people), Tank and Tank Universal (1-25 people). These are 3-chamber tanks with the ability to increase the stages of wastewater treatment by adding additional blocks;

- bioremediation systems. Energy-dependent VOC Biotank (4-10 people) and Eurobion (4-150 people) made of HDPE and polypropylene, respectively.

The main material for the manufacture of containers is HDPE. The thickness of the material ranges from 10 to 15 mm depending on the model and location. For example, it is greater near stiffening ribs, and less on straight lines or areas of slight curvature.

The video below clearly demonstrates the production of HDPE Tank models. The plant is equipped with modern equipment; sheet plastic is supplied from Russian, Czech and German manufacturers.

| Model | Tank-2 | Microbe-450 | Biotank-3 itself* |

|---|---|---|---|

| terms of Use | For a family of 3-4 people with permanent or seasonal use. Works at low groundwater level, soil – sand, sandy loam, loam. | Model for seasonal use. Operation by 1-3 people in economy mode. For low groundwater level and filter soil. | Seasonal accommodation for up to 5 people. Low groundwater level, sandy or loamy soil. |

| Short description | Cast horizontal 3-chamber settling tank with developed stiffening ribs. Can be equipped with an infiltrator** (analogue of a filtration field). Soil post-treatment of wastewater is required. | Compact vertical septic tank with 2 chambers. Provides minimal purification from heavy and light fractions. It is necessary to arrange a filtration field. You can additionally purchase an infiltrator. | Vertical 4-chamber septic tank with aeration section. Installed 1 compressor and simple automation. The degree of wastewater treatment is 95-98%; after the station, it can be discharged into a roadside ditch. |

| Material | HDPE 10-15 mm thick | HDPE 10 mm thick | |

| Size, L×W×H or D×L, mm | 1800×1200×1700 | 810×1430 | 1020×2120 |

| Electricity consumption, W/h | — | — | 60 |

| Weight, kg | 130 | 35 | 100 |

| price, rub. | 50500 | 16500 | 42500 |

* This is a model with gravity drainage of treated wastewater. There is a modification with installed pump for forced withdrawal. There is also a model with a horizontal design.

** The infiltrator looks like it's upside down plastic bath, serves as the boundary of the filtration area of treated wastewater.

Conclusions: even though this manufacturer has models different types, it is known more for its settling tanks. The Tank series line is ideal for dacha conditions and, in certain cases, can be used for permanent residence. During production, HDPE with a thickness of 10-15 mm is used, which is not always enough to ensure structural rigidity when installed in difficult soils.

5. “Multplast” – Termite septic tanks

at a price of 25,000 rubles.

The Multplast company specializes in the production of products made of polyethylene and fiberglass: septic tanks, caissons, wells, etc. This manufacturer is known for its Termite and Ergobox product lines. The plant has been operating since 2004 and is located in Vologda region, Cherepovets. The company has its own warehouses in Moscow, St. Petersburg, and also in the Krasnodar region. They deliver throughout the Russian Federation thanks to a developed dealer network.

Production technologies and range

The equipment is represented by 2 main product lines:

- settling tanks. Produced under the Termite brand. Includes several modifications: Pro – 2- and 3-chamber septic tanks for dachas with low groundwater level; Transformer - the same as Pro, but with one neck (more rigid design); Transformer PR is a modification with a pump for forced pumping of treated wastewater at high groundwater levels. There are also storage models with a capacity of up to 5.5 cubic meters;

- biological treatment stations. Produced under the Ergobox brand. They are modifications of Transformer (PR) models in which a compressor and aerators are installed.

All these products are made using rotational molding from Korean-made HDPE. The result is a durable, seamless structure with developed stiffening ribs. The wall thickness is 20 mm.

| Model | Termite Pro 3.0 | Ergobox 6 S* |

|---|---|---|

| terms of Use | For a family of up to 6 people at low ground level, when the soil is sand, sandy loam, loam. | For a family of up to 6 people with a low groundwater level, because the gravity version. The type of soil does not matter. |

| Short description | 3-chamber horizontal settling tank for primary treatment under anaerobic conditions. It is necessary to install a filtration field for wastewater treatment. | 3-chamber VOC in horizontal design with a Japanese compressor and a German pump. Discharge of treated wastewater into a ditch, onto the terrain, into the ground. |

| Material | HDPE 20 mm thick | |

| Size, L×W×H or D×L, mm | 2300×1155×1905 | 2000×1000×2100 |

| Electricity consumption, W/h | — | 63 |

| Weight, kg | 165 | 137 |

| price, rub. | 52100 | 73700 |

* S – gravity flow. There is a PR modification with a pump for forced pumping out of treated wastewater. It costs 6 thousand rubles. more expensive than the gravity version.

Video demonstrating the installation process of a Termite septic tank. From a short video you will also learn about what diameter the supply pipe should be, whether it can have 90-degree turns, how and where to discharge the treated wastewater, etc.

Conclusions: It’s easy to notice the similarity of products from “Multplast” with products like Tank. All the same pronounced stiffening ribs and simple design. Of particular interest may be versions with a compressor - a simple modification gives the design special properties. However, it must be taken into account that a small number of chambers can lead to poor quality of wastewater treatment and, as a consequence, the need to construct a filtration field or well for additional treatment.

6. “Eurolos” – Eurolos cleaning systems

at a price of 26,000 rubles.

The Eurolos company is a relatively young company; the plant has been operating in the Moscow region since 2015. It gained considerable popularity due to the production of high-quality plastic products: wastewater treatment systems, caissons, grease traps. Deliveries from the manufacturer are carried out from a warehouse in Moscow, throughout the country - through a developed dealer network.

Production technologies and range

Cleaning equipment is represented by 2 lines:

- for individual use. This is Eurolos Udacha - a compact septic tank for seasonal use in the country; Eurolos Eco – 3-chamber settling tank; Eurolos Bio – VOC with pump and ejector; Eurolos Pro – aeration SBO. They are designed for a family from 3 to 20 people;

- for collective use. This is Eurolos Kontus - a modular system for wastewater treatment. Capacity from 20 to 4000 cubic meters per day.

All containers are made from polypropylene sheets 8-10 mm thick. In the Bio model, oxygen is supplied not by a compressor, but by a pump + ejector combination. How this works is clearly shown in the video below.

We also recommend looking at a full review of this treatment station, which explains the principle of operation of the system and the role of each of the components. We focus on the Bio model because it is the most popular among Eurolos buyers.

| Model | Luck | Eco 1 | Bio 5 |

|---|---|---|---|

| terms of Use | For a family of 2-3 people with seasonal living and economical use of water. The ground level is low, the soil is sandy loam or sand. | For a family of 5 people for permanent or seasonal use. The groundwater level is low, the soil has good filtering abilities. | For 5 people for permanent or seasonal stay. Any ground conditions. |

| Short description | Compact 2-chamber settling tank. Does not require digging a deep pit. A filter field must be installed. It is also recommended to use bacteria. | Horizontal 3-chamber settling tank with brush loading for breeding colonies of anaerobic bacteria. Additional soil treatment facilities are required. | Vertical VOC of 3 chambers and a biofilter with wastewater circulation throughout the entire circuit. Aeration due to ejector and gushing. Does not require soil purification - wastewater can be discharged onto the terrain or into a ditch. |

| Material | Sheet polypropylene 8-10 mm thick | ||

| Size, L×W×H or D×L, mm | 1500×1500×800 | 1000×2000 | 1400×2000 |

| Electricity consumption, W/h | — | — | 88 |

| Weight, kg | 69 | 84 | 165 |

| price, rub. | 26000 | 43000 | 71000 |

The kit does not include accompanying structures for arranging a treated wastewater discharge system. An infiltrator will cost an additional 5,600 rubles, a well - from 21,000 rubles, submersible drainage pumps - from 2,900 rubles.

Conclusions: In the range of the Eurolos company you will find solutions for the construction of a local treatment plant for seasonal and permanent residence of different capacities and the degree of preparation of wastewater for discharge into the external environment. It should be noted that the basic set of equipment is affordable, however, due to the small thickness of the tank walls, we do not recommend installing such systems in difficult soils where there is a possibility of the structure being compressed.

7. “Ekoprom” – septic tanks Rostock

at a price of RUB 26,800.

The Ecoprom company has been producing products from recycled polyethylene since 2008. The range includes containers for water, fuels and lubricants, septic tanks, grease traps, tanks for shower cabins, etc. Today there are 3 factories in the Moscow and Leningrad regions.

Production technologies and range

2 product lines are designed for local sewerage installations:

- drives. Rostok U sealed containers with a volume from 1250 to 3000 liters.

- settling tanks. These are 2-chamber septic tanks Rostock Mini, Dachny, Zagorodny, Cottage. Volume from 1000 to 3000 liters - this is enough for use by a family of 2-6 people.

All containers are made from recycled materials, which determines their competitive cost. The tanks are made from HDPE using rotational molding. In this case, the wall thickness is 10-12 mm.

Watch a 2-minute video that clearly shows the structure of the Rostock Dachny septic tank and describes the role of each element of the treatment system.

| Model | Rostock Dachny | Rostock Countryside | Rostock Cottage |

|---|---|---|---|

| terms of Use | For 2-3 people. | For 4-5 people. | For 5-6 people. |

| Seasonal residence, low ground level, soil - sand, sandy loam. | |||

| Short description | 2-chamber horizontal settling tank with developed stiffeners. A filter field must be installed. Salvo discharge and the use of aggressive chemical substances. | ||

| Material | HDPE 10-12 mm thick | ||

| Size, L×W×H or D×L, mm | 1680×1115×1840 | 2220×1305×2000 | 2360×1440×2085 |

| Electricity consumption, W/h | — | — | — |

| Weight, kg | 85 | 125 | 160 |

| price, rub. | 33800 | 49800 | 58800 |

The price does not include an infiltrator for constructing a filtration field. This is about another 7,000 rubles. a piece.

Conclusion: Are you looking for the simplest sedimentation tanks for your dacha and their main quality for you is strength, tightness and affordable cost? Then you should consider purchasing a septic tank from Ecoprom. Especially if we're talking about about the dacha, and the plot is located somewhere on the outskirts of the partnership. Because the quality of pre-cleaning, due to the presence of only two chambers, leaves much to be desired.

8. “NEP-center” – Eurobion cleaning systems

at a price of 84,000 rubles.

GC "NEP-Center" has been specializing in the production of local treatment facilities for low-rise buildings since 1998. The plant is located in the Moscow region, Kubinka. The company has a powerful scientific and technical base for developments in the field of wastewater and drinking water treatment. Delivery throughout the Russian Federation through the dealer network.

Production technologies and range

All systems are equipped with active wastewater aeration and are allocated general group- aeroseptics. Depending on the model, they can satisfy the needs of 4 to 100 people. According to the company’s engineer-inventor, Yu.O. Bobylev, NEP-Center products are the result of the evolution of the VOC Topas line.

| Model | Eurobion-5 ART | Yubas 5 |

|---|---|---|

| terms of Use | VOC for constant use by a family of 5 people. Any ground conditions. | |

| Short description | 4-section vertical installation with a large receiving chamber capable of withstanding a salvo discharge of up to 390 liters. It features economical energy consumption. Treated wastewater can be discharged onto the terrain. | Vertical station with deeper cleaning. Capable of receiving a salvo discharge of up to 700 liters. Consumes more electricity. It has complex system automation, which complicates repairs. The wastewater after the system is discharged onto the terrain. |

| Material | Sheet polypropylene 10 mm thick | |

| Size, L×W×H or D×L, mm | 1080×1080×2380 | |

| Electricity consumption, W/h | 39 | 60 |

| Weight, kg | 125 | 270 |

| price, rub. | 85000 | 138000 |

Station maintenance – important stage operation of the system. From the video below you will learn not only how to maintain VOC Eurobion 5, but also how the station is cleaned and what role is assigned to each of its components.

Conclusions: Treatment facilities from NEP-Center have a well-thought-out design in terms of the efficiency of wastewater treatment, but their maintenance requires highly qualified workers. Such systems are excellent for continuous use, but at the same time their cost is higher than their analogues.

9. Trade House "Engineering Equipment" - septic tanks Tver

at a price of 67,900 rub.

The company TD "Engineering Equipment" has been operating since 1992 and specializes in scientific research, production, construction and installation of equipment for wastewater treatment and pumping. The company's product range includes LOS Tver, storm water treatment facilities in Svir, grease traps, and wastewater treatment plants for car washes in the Northern regions. Production is carried out at 4 factories in the Russian Federation.

Production technologies and range

- for private houses. Biological treatment stations made of polypropylene of the Tver-P line are designed for 2-36 users, depending on the performance of the system;

- for residential complexes. Cleaning equipment in a metal or polymer housing with high capacity for 30-1500 people.

- for rotation camps. Container version Tver-S for 6-1000 people;

- in block-modular design. Modular designs Tver-BM with flexible adjustment of wastewater flow by varying the number of connected blocks;

- for solid waste landfills. Specialized Tver-MSW stations in container design for deep treatment of wastewater from solid waste landfills.

All models of Tver treatment systems are energy-dependent installations for seasonal or permanent residence. Polypropylene with a thickness of 5 mm is used as the material for the walls of the containers. The rigidity of the structure is ensured by stiffening ribs and internal partitions.

* There are 7 more modifications of this station, for example, the model with the PN index has a pump compartment with submersible pump For forced submission treated wastewater.

The video below shows detailed information about installing a septic tank Tver-0.75 PN. A company representative at a real site explains the structure of the system and the role of each of its elements. Station maintenance is described in detail. If you are thinking about buying this model, be sure to check it out!

Conclusions: TD " Engineering equipment» do not offer a large selection of systems for country houses. The guys simply developed a model that works well and scaled it up. The result is not the most compact water purification station at an average price. The main thing is that it works, right?

Editor's Choice

All the presented manufacturers are good, but we especially want to highlight the following:

- "Aqua Hold". For septic tanks Leopard: a large selection of models of different types, the durable body of which is made of HDPE with a thickness of 25 mm. You can choose a treatment facility for any conditions. There are solutions for summer cottages, for permanent residence, for low and high groundwater levels, and for various types of soil. Product prices are average for the market.

- "Elite Stroy Invest". For simple septic tanks Tank, which are ideal for a summer residence - durable, reliable, priced from 25,000 rubles.

- Trade house "Engineering equipment". For biological treatment stations Tver. Unlike most VOCs, it not only copes with the task of cleaning wastewater, but is also easy to maintain - no need to call a specialist. This is possible thanks to easy access to each station camera.

FAQ

Here we have collected answers to current issues about septic tanks.

What material is the best septic tank?

Factory products for individual use are made from polymer materials: polypropylene, polyethylene low pressure(HDPE), fiberglass. They are relatively light, do not corrode, are strong, sealed and durable - all these materials are good.

The only question is to what extent their capabilities are realized in a particular septic tank design. For example, there may be a polypropylene container in which the seams are welded poorly, so it will leak after some time.

The rigidity of the structure is influenced by the thickness of the material and the presence of structural elements: stiffeners and internal partitions. Therefore, if the design is unsuccessful or simply does not suit specific operating conditions, the septic tank can be flattened or torn apart by soil. But the point here is not in the quality of the material from which it is made, but in the design itself.

I can’t decide between a non-volatile septic tank and a biological treatment station with aerators. What's better?

If for a summer residence, choose a non-volatile sump tank, provided that the groundwater level is below 1.5 meters, and the soil itself has good filtering abilities. For example, it is sand or sandy loam. Once a season you have to do it dirty work and remove accumulated sludge from the bottom of the container, however, in general, this solution is the most economically feasible and convenient for seasonal living.

For private homes, it is better to buy a system that ensures maximum purity of wastewater leaving the treatment plant. You can’t do without a station with aerators. One of the advantages: the wastewater does not smell after it, it is cleaned so much that it can be poured into roadside ditches. However, this solution is more expensive, and automation and compressors require connection to the electrical network.

Summer cottage near the forest, seasonal accommodation, four people. Recommend a septic tank.

If you need something cheaper and simpler, then consider the Termite Pro 2.0 option. It is very similar to the well-known Tank, but costs only 39,000 rubles. The manufacturer also often has promotions - you can save several thousand.

The filtration field can be set up next to the forest. This is where you will dump wastewater for further treatment. This way you will cause minimal inconvenience to yourself and your neighbors.

At the dacha there is a well from which water is used for food purposes. Which septic tank to choose?

Obviously, a treatment station is required here, after which the wastewater can be discharged into a roadside ditch. If there is no ditch, it can be lowered into the ground, provided that the discharge point must be 50 m from the well.

If the soil does not accept water, then in some cases it makes sense to think about installing a storage tank and then calling the vacuum cleaners.

Will the drains freeze in winter? Is it necessary to insulate a septic tank?

If used constantly, they will definitely not freeze - a kind of bioreactor is constantly working inside, generating heat. In extreme cases, you can insulate it by pouring a layer of straw or leaves on top.

During seasonal use, it is recommended to fill the container 2/3 with drainage, additionally insulating it on top. This way the container will not float up and be crushed by frozen soil. We recommend that you additionally read the instructions for the specific model; the manufacturer may have a different opinion on this matter.

What happens to a volatile water treatment plant if the power goes out?

Typically, such systems are very sensitive to power outages. The compressor pumping air stops working, and after 6 hours the amount of oxygen in the wastewater is significantly reduced. The struggle begins between aerobes and anaerobes. Effluent can begin to ferment due to anaerobes, so after turning on the electricity, normal operation occurs within several days.

Is there a strong smell from the septic tank?

After a regular septic tank there is a strong, characteristic smell of sewage. It can be felt even close to the filtration field, so they are installed in the most remote place.

After systems with aeration, the water is cleaner and does not smell. Unless the station's operating mode is disrupted: exceeding the permissible peak discharge, power outage, use of aggressive detergents.

Installed a septic tank with a filtration field without connecting to the power supply. How to service it?

Once every six months it is necessary to open the container and check the amount of sediment. If it is more than 1/5 of the height of the container, it will have to be removed. Use a bucket or fecal pump for this purpose.

Light fractions will accumulate on the surface of the wastewater. If they form a thick, hard layer more than 5 cm thick, it is also better to remove it in a timely manner, because it can subsequently significantly complicate cleaning the tank.

It should be clear from the very beginning: making a septic tank for a dacha without pumping it yourself is a kind of convention. Even with the most careful approach to the design and implementation of the project, the resulting structure will require condition monitoring and correction of work, and pumping will still be required, although its frequency will be approximately 10-15 years. It is thanks to such a rare need to use the services of a sewage disposal machine that treatment plants of this type got their name.

There are many ways to make a septic tank without pumping with your own hands. They differ in the materials from which the containers are made, the need to use electrical equipment, performance and the number of chambers connected in series. At the same time in general outline the principle of operation is preserved in all these structures.

Particles of pollution settle to the bottom of the containers during the settling process, and aerobic or anaerobic (needing or not needing an influx of oxygen for their life) bacteria transform the complex sediment into neutral, non-toxic sludge. The water is purified in several stages. In each of the series-connected reservoirs, smaller particles are deposited than in the previous one. Clarified water flows into the next container. In the last reservoir, it drains into the ground or leaves it for filtration fields.

Note: Three-chamber septic tanks for dachas without pumping are considered the most effective, although two-chamber options are often used.

From the point of view of the principle of operation, two types of structures should be distinguished:

- Energy dependent Septic tanks are equipped with a compressor to supply the air needed by aerobic bacteria, and, in some cases, a fan for more effective removal gases formed as a result of the vital activity of microflora.

- Non-volatile Septic tanks without pumping operate without any additional equipment.

The advantage of a septic tank for a dacha without electricity is its ease of implementation and the absence of additional operating costs, however Volatile septic tanks operate more efficiently. They clean wastewater more efficiently (up to 98%), and you need to think about how to clean a septic tank without pumping such a structure much less often.

Materials for production

A septic tank without pumping and odor can be built with your own hands from available materials, but when choosing, you should take into account their characteristics, design and installation features. Let's list the most common options.

1. Stacked on top of each other provide the required durability and strength. The advantage of this option is the rigidity of the structure, which is not subject to compression by the soil when the soil freezes.

The disadvantages include the complexity of installation, the need to use special equipment (lifting devices for transporting and installing heavy elements), as well as the need for external and internal waterproofing not only of the joints, but also of the entire surface of the containers.

2. Installation of country septic tanks without pumping out old car tires is carried out in a similar way - the elements are installed on top of each other using a suitable fixing compound and mandatory sealing of the joints. The advantages of such septic tanks are ease of transportation and installation of elements with low mass, no need for waterproofing the walls of the chambers, and low cost.

However, for a large family you will need tires large diameter or a significant height of the container to ensure the required volume (triple daily water consumption). The plasticity of the walls can cause a leak in the septic tank after the soil freezes. The compressed tires will regain their shape, but the integrity of the joints may be compromised. The service life of such septic tanks is short and their use is justified only for small amounts of wastewater.

3. Eurocubes, which appeared on the domestic market, have become incredibly popular. Their low cost, durability, water resistance and large capacity with compact sizes allow the use of such products for a variety of purposes. It is quite possible to make non-volatile septic tanks for your dacha yourself without pumping out of Eurocubes.

The installation of a septic tank structure in this case has its own characteristics. The Eurocube has a very low dead weight, which makes it easy to transport the material and install containers in the pit, but it can create some problems during operation. For example, during a flood or when groundwater reaches the surface and when the tanks are not full, the septic tank may “float”.

This unpleasant situation can be avoided by fixing the Eurocube on a heavy base. As the latter, concrete or reinforced concrete slabs, and fastening is easiest to do with the help of some kind of clamps. This method will ensure a reliable connection without damaging the integrity of the Eurocube.

4. without electricity and pumping is not only one of the most economical and durable options. Unlike its ring counterpart, it does not require the use of special equipment. It is enough to deliver building materials to the site; the rest can be done manually or using household power tools. A feature of the construction of a monolithic septic tank without pumping is presence of one total capacity , which is divided into two or three parts to organize several stages of purification.

It will take more time to complete the work than for other structures, since pouring the bottom and formwork of the walls with concrete is carried out in stages, allowing time for the next poured block to harden. For a two-cube monolithic septic tank with one partition (two-stage cleaning) you will need approximately 400 kg of Portland cement. The container will have optimal technical characteristics if a plasticizer is added to it when mixing the solution (about 5 liters will be required for this amount of dry construction mixture).

5. Brick walls also require waterproofing. In addition, when building septic tanks from this material, it is better to build rectangular containers. This septic tank without pumping for a house or summer cottage is not very popular except in cases where leftover material is used after the construction of other structures.

General principles of construction and selection of septic tank options

There are general principles for the construction of septic tanks that are valid for structures made of any materials.

Septic tank maintenance and work monitoring

Treatment facilities of this type require certain control over their operation. To prevent septic tank overflow, level sensors are often installed. Similar equipment may be required when using bilge pumps to prevent air entrapment.

With periodic residence at the dacha and interruptions in operation, aerobic and anaerobic bacteria in the septic tank may die. You can restore the operation of such a structure by adding culture purchased from a specialized store through the sewer.

One of the reasons for the deterioration of the performance of an energy-dependent septic tank with aerobic bacteria may be an insufficiently intense air flow. It is best if the installed compressor has the ability to regulate performance to be able to select the optimal mode.

If you don’t want to build a septic tank without pumping yourself, you can purchase ready-made factory models. The principle of biological decomposition of organic matter is used in septic tanks for deep cleaning stations Tver, Topol and Topas.

You can also watch a video on the topic of our article, in which you will find a diagram and tips for organizing a septic tank yourself.

Prejudice towards local sewer systems is associated with experience in servicing simple drainage pits. Autonomous drainage is associated with regular drainage of the receiver with the entry of a heavy sewer truck into the site, and a constant persistent odor that cannot be gotten rid of even after disinfection. The situation is changing with the installation of modern autonomous sewerage stations - odorless and systematic pumping. There are several types of sewer systems that operate both connected to the electrical network and in completely autonomous mode. A variety of ready-made solutions allows you to choose the optimal design for a country house, summer cottage, mini-hotel or cafe.

In addition to the size of the budget planned for sewerage installations, several objective factors are taken into account when choosing a wastewater disposal method:

- Location and area of the site: simple designs can be installed in areas remote from the city limits, for arrangement in summer cottages with seasonal use. There must be enough space on the site to comply with the rules for placing waste tanks.

- Groundwater point: Most systems are installed so that the discharge is above the groundwater level.

- Availability of proper electrical wiring and uninterrupted power supply. Autonomous systems for private sewerage, operating without pumping, equipped with pumping groups and compressors.

Invisible sewerage: on the surface - only the inspection hatch cover

It should be remembered that any system will have to be serviced regularly, but the frequency of activities can be reduced to pumping every few years using regular drain pump.

Deep cleaning system: diagram

Odorless pit or septic tank: a simple solution

Most cheap way arrange an autonomous sewage system without an unpleasant odor - install a sealed drain tank. Instead of dumping waste into a hole dug in the ground, use impenetrable plastic containers. Tanks made of polyethylene or PVC are sealed and equipped with a hatch with a seal that does not allow air to pass through. A pipe from the home sewer is connected to the top of the receiver. A septic tank is dug in so that the hatch protrudes 20 cm above the ground surface.

The drainage pit will have to be pumped out frequently: access for a car is required

The advantages of a drain septic tank or pit are simplicity of design and low cost. But these are the only advantages, and they are also dubious. The liquid will have to be pumped out regularly - at least once a month. Savings on the design are offset by the cost of visiting a sewer truck and the large volume of excavation work during installation, because the container must accommodate the monthly volume of drainage with a margin of 20 - 30%.

A simple drain system is not suitable for servicing a private house if the number of family members is more than two, and the cottage is lived in all year round. Heavy use household appliances doubles water consumption. There is no point in saving on sewerage and paying weekly for pumping.

Non-volatile systems for operation without an electrical connection

Budget-friendly design with reduced pumping frequency and odorless – active septic tank. Autonomous sewerage of this type is energy-independent and can be installed in areas where there is no electricity - to serve seasonal cottages.

A septic tank consists of one sealed or two containers connected by an overflow. A single-chamber structure is installed when the groundwater level allows drainage from the tank directly into the ground.

Anaerobic septic tank: non-volatile sewerage

Cleaning takes place in the main receiver and takes 72 hours. Therefore, there is no need to install large tanks. The volume of the container must be sufficient to accommodate 3 maximum daily volumes of wastewater, with a margin of up to 40%. The liquid level inside the structure should not exceed 75% of the internal volume.

Waste treatment occurs under the influence of anaerobic microorganisms that process organic compounds. Sewage flows through the inlet from the sewer, and a dense, greasy crust gradually forms on the surface of the liquid - a habitat for bacteria.

Drain cleaning scheme in the housing

Solids that do not dissolve settle to the bottom. The purified liquid is discharged into the ground through a filter tunnel or well with gravel bed and sand, which further purifies the water before seeping into the ground.

An active septic tank must be equipped with ventilation. To prevent the autonomous sewer system from spreading an unpleasant odor, the outlet is raised to a height of up to 3 - 5 m. It will not be possible to do without pumping for a long time: part of the sludge is removed from the receiving tank several times a year.

Cleaning stations: flow-through designs with complete cleaning

The only solution that makes it possible to organize an autonomous sewage system without odor and without pumping special equipment– installation of a local treatment station (VS). The systems are designed using multi-stage processing technology. Effluents entering the VOC undergo mechanical, biological and chemical cleaning.

Autonomous treatment station: location on site

Deep processing of waste and final disinfection contribute to the complete purification of wastewater - the degree of purity is from 95%. Such water is allowed to be disposed of - discharged onto the terrain, into reservoirs and ditches. Also, clarified wastewater can be used as process water for construction and domestic needs: watering plants, filling landscape ponds and swimming pools.

Autonomous stations: deep processing without pumping and unpleasant odor

Deep cleaning stations use electrical equipment, and control is carried out by an electronic control unit located inside the housing. Therefore, it is possible to install autonomous sewage systems only in areas with a stable power supply. The stations cope with short-term power outages - they operate in autonomous mode for several hours.

Multi-chamber horizontal cleaning station for home sewerage

Structures: what does the sewerage system consist of?

Autonomous sewage systems without pumping and odor – complex designs with built-in equipment. The housing, depending on the capacity and estimated volume of processed waste, may consist of one or two separately located tanks.

Containers are made from several types of materials:

- Polyethylene. The advantage of tanks is the absence of seams. Since the body is constantly in the ground, it experiences a double load: aggressive liquid accumulates inside, and a mass of soil with stones presses on the walls outside. The absence of seams makes the structure almost eternal - the tanks do not crack, do not leak, the walls do not rot and are not subject to corrosion. Plastic tanks do not require insulation - the material is multi-layered and can withstand down to -30 o.

Vertical system in a polymer housing

- Polymer with added fiberglass. Fiberglass with the addition of fiberglass is more durable than PVC and polyethylene, but structures made from this material are much more expensive. Glass and plastic housings are used to manufacture systems that are intended for installation in commercial facilities or as a sewer system for several houses. The stations have enough capacity to dispose of waste from buildings inhabited by up to 200 people.

- Metal. Metal structures consist of 2 parts. A plastic tank is installed inside the welded metal body. Metal is less preferable as a sewer system body: the seams quickly lose their tightness, and damage to the protective anti-corrosion layer leads to rust.

Inside the housing there are several (up to 4) separate sections for step-by-step treatment of wastewater. The chambers are separated by blank walls with holes for pumping liquid into the next compartment, or walls with an overflow.

The main compartments are a mechanical and primary cleaning chamber (sump); aeration tank (deep biological treatment compartment) and finishing unit. The buildings of the treatment stations are equipped with preparation for connection to the home sewerage system - standard size pipes with seals.

Inspection hatches are equipped with sealed covers with locks so that no unpleasant odor appears in the area where the autonomous sewage system is installed. Depending on the type of biological treatment, structures may be equipped with a ventilation outlet, which is led into the home ventilation at the roof level. In stations without anaerobic treatment, ventilation is not installed.

Equipment and internal organization

- Mechanical filters with debris catchers.

- Drainage pumps with grinders - for crushing solid waste and reducing the amount of sediment in the receptacle.

- Compressor equipment with a control unit - to saturate the biofiltration chamber with oxygen.

- Module with chemical disinfectants or blocks with bulk absorbents in the final cleaning chamber.

Cleaning mechanism: waste processing stages

How does an autonomous sewage system work that does not require pumping and processes odorless waste? The wastewater undergoes complex step-by-step processing. In the first stage, the liquid is pumped through the home sewer outlet into a sump. The chamber is equipped with mechanical filters, grease and debris traps. High-power stations are equipped with electric waste shredders to prevent sediment from accumulating at the bottom. In the receiving compartment, a natural process of liquid stratification also occurs - water rises up, and insoluble masses settle at the bottom.

Diagram: sequence of passage of drain inside the housing

Through the overflow hole, or with the help of an electric pump, the waste flows into the compartment where deep cleaning occurs - into the aeration tank. Over the course of 3 days, the wastewater is biologically processed to obtain water that is 70% purified at the outlet. After the process is completed, the liquid is supplied to the finishing chamber. In the last compartment, filtration and disinfection take place - the purity at the outlet is up to 99%. Chlorine is used as a disinfecting component in a safe form - slowly dissolving tablets. For mechanical purification, blocks with carbon and mineral bulk filters are used.

After processing, the wastewater is removed from the sewer by a pump. Draining is organized in several ways:

Methods for removing treated waste

- A filtration well or tunnel is installed through which purified water enters the ground.

- They make a forced diversion into a natural body of water, a ditch, or a ditch.

- The water is discharged to a receiving tank on site for further use.

How does deep biofiltration work?

In the deep cleaning chamber, the aeration tank, the main process of processing sewage waste occurs. In this case, the main work is performed by living organisms - aerobic bacteria. Microorganisms live in a mass of activated sludge consisting of brown flakes.

Compressor equipment in the aeration tank

Under the influence of oxygen pumped by the compressor, the processing process is activated due to the accelerated proliferation of bacteria. Microorganisms absorb and break down organic compounds. The liquid, freed from organic contaminants, rises, and activated sludge, consisting of bacteria and dense masses, remains at the bottom.

The more oxygen is supplied to the chamber, the faster the number of microorganisms increases, and accordingly, the cleaning process accelerates. The technology is universal: there is no need to add biological products; self-regulation of the number of living organisms allows you to control the speed and intensity of the processing process.

Biofiltration using an aerobic system

The stations have no restrictions on the composition of the processed waste, unlike active septic tanks (anaerobic), sensitive to household chemicals and drug residues. The systems cope with standard amounts of detergents and other chemicals that end up in the sewer.

Installation rules and restrictions on installing local sewerage

Autonomous sewerage, which operates odorless and does not require pumping, is the only type cleaning systems, which is permitted for installation in areas with a limited area within the city. Installation restrictions and requirements:

- The distance from the foundation is 5 m, but if there is not enough space, it is allowed to reduce the distance to 3 m.

- There should be at least 2 - 4 m to the fence or border of the neighboring plot.

- Installation in the city is allowed, as well as for servicing several residential buildings.

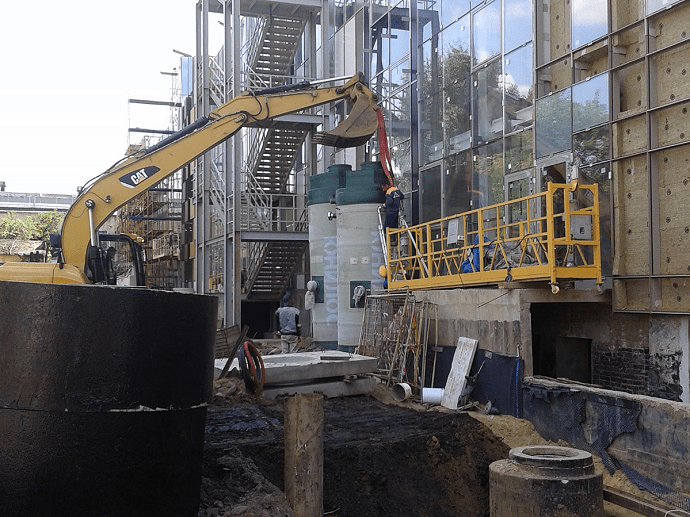

Organizations accredited by the station manufacturer have the right to carry out installation: a representative of the manufacturer supervises the installation process. The second option is to order stations with installation directly from the manufacturer, and carry out the preparatory excavation work yourself.

The installation pit is dug with a reserve depth to form a solid foundation. The bottom is filled with mortar, slabs are installed or backfilled with sand on a crushed stone bed. The base must be strictly horizontal and level.

The location for the pit is chosen so that the sewer pipe from the house is laid with a minimum number of turns and height changes, preferably in a straight line. In this case, the pipe is installed at an angle so that the liquid flows freely into the receiving chamber. Pipe diameter – from 100 to 120 mm. Manufacturers recommend using plastic parts for the pipeline - PVC or polypropylene.

Cleaning station maintenance: regular activities

Manufacturers of cleaning stations indicate in the instructions the list and frequency of preventive maintenance. General rules:

- The drain is inspected weekly and two parameters are checked: transparency and odor. The liquid exiting the autonomous sewer system must be absolutely colorless, without impurities or unpleasant odor.

- If the receiving compartment is equipped with debris catchers, then remove the baskets for cleaning once every few months. Access is through the hatch.

The basket is removed through the hatch cover

- When using chlorine for disinfection, you need to systematically install a new tablet into the module - approximately once every 14 days.

- The amount of waste that will have to be removed from the station is negligible. The total volume varies from 60 to 90 liters per year. Biological treatment chambers are cleaned once after several years of operation. You can drain the compartments yourself using a home drainage pump.

- Replacement of consumable parts and maintenance of electrical equipment is carried out exclusively by representatives of the manufacturer - usually 10 years after the launch of the station.

Video: how to select and install an autonomous sewer system

When choosing a system, you should not focus only on cost. Contact a company that deals with sales and installation - they will help you choose an autonomous sewerage station with the optimal combination of price, power and quality. Also, experts will take into account everything individual characteristics: they will predict the volume, analyze the relief and technical characteristics of the site.

Cesspool - the simplest, but not too good option autonomous sewerage system in a private house. Modern technologies offer more convenient solutions, such as local treatment stations industrial production.

A skilled builder is quite capable of making a septic tank with his own hands without pumping. What options for odorless septic tanks are popular among owners of private houses and what is required for their construction - we will consider all this in our article.

We will also give an example of assembling a septic tank from concrete rings and compare ready-made solutions, offered by the market, with homemade products.

Septic tanks are sewer facilities that almost completely recycle wastewater, decomposing it into safe components.

All work on the transformation of human waste is assigned to microorganisms. Aerobic and anaerobic bacteria gradually convert unappetizing sewage masses into water and activated sludge.

Image gallery

If the device is insulated and properly preserved, it is not afraid of any winter frosts, nor spring floods. It will not float or crack, even if some of its contents freeze.

It is important, of course, to install the device correctly. During wastewater treatment, bacteria effectively eliminate the characteristic sewage odor.

The resulting water, of course, is not suitable for drinking, cooking, washing or other household needs. With a high degree of purification, it can be used to water plants on the site.

Often water is removed through a filtration well or filtration field. Water gradually enters the soil, passing through a purification system, a layer of sand and crushed stone.

Silt that settles to the bottom sealed container, of course, is not going anywhere. It accumulates, as a result of which the total volume of the septic tank decreases slightly. When the amount of deposits becomes critical, the device should be cleaned using a special pump.

Cleaning a septic tank is performed much less frequently than pumping it out. cesspool, and this process is usually not accompanied by a stench, since the sludge has a completely neutral odor.

Image gallery

Image gallery

The outside of the septic tank is covered with a layer of waterproofing. Some craftsmen recommend lubricating not only the joints, but the entire container of the device

The trench for the sewer pipe leading from the house to the septic tank without pumping and odor is laid with a slight slope. At the junction of the septic tank and the pipe, a hole of suitable dimensions is made in the thickness of the concrete.

In the same way, overflow pipes are installed that connect the individual parts of the septic tank. All connections between the septic tank and pipes must be sealed and covered with a layer of waterproofing.

At the bottom of the last section of the septic tank instead cement mortar lay a gravel-sand filter. First, sand is poured and leveled, and then a layer of gravel is added.

It is also possible to use crushed stone of a suitable fraction for these purposes. The thickness of the filtration layer should be approximately 30-40 cm.

As the top cover of a septic tank made of concrete rings, a special round slab of suitable size with a sealed lid is used

After all the compartments of the septic tank are ready, you need to cover them with round concrete slabs, which can be purchased from reinforced concrete manufacturers complete with concrete rings.

These lids have holes with sealed concrete lids. All that remains is to backfill the pits, and the septic tank can be considered ready for use.

Other options for homemade septic tanks

In addition to concrete rings, other materials can be used to create a septic tank. Let's consider the most popular materials and options for manufacturing septic tanks.

Option #1 – septic tank from a Eurocube

We have already mentioned the Eurocube - a sealed plastic container.

Installing such a septic tank is relatively easy, but the low physical weight of the plastic should be taken into account. During a spring flood, groundwater can simply push a light container to the surface.

To make such a septic tank heavier, a concrete slab with metal hinges should be laid at the bottom of the pit. The container is fixed to these loops using metal cable. Sometimes such a septic tank is made heavier with the help of some heavy object, which is fixed at the top of the device.

Option #2 – monolithic concrete structure

A concrete septic tank can be made using pouring. In this case, it is not necessary to make several pits; you can get by with one large structure and a rectangular configuration.

First, the bottom is concreted, then the formwork is installed and the walls of the septic tank are poured. To divide a large container into several sections, concrete walls are made inside.

To fill a concrete septic tank using a solution, you will need to build wooden formwork, in which holes are immediately made for overflow pipes

You can make a septic tank with your own hands from concrete blocks or bricks, but the masonry must be as airtight as possible.

Another option is to make. However, such material cannot provide sufficient tightness to protect the soil from untreated wastewater.

Using tires, you can only make a permeable cesspool. The service life of such a device is significantly limited, in contrast to a capital septic tank, which, with proper maintenance, can last for decades.

Conclusions and useful video on the topic

This video presents in detail the option of creating a two-chamber septic tank:

Of course, a homemade septic tank does not always provide the same high degree of purification as modern VOCs. But still, these structures function very successfully at relatively low costs for their installation and maintenance.

When constructing a septic tank, it is important to adhere to technical standards to prevent groundwater contamination.

Do you use a homemade septic tank without pumping? Tell us what type of structure you preferred and does your family have enough volume? How often do you clean and what steps do you take to prepare your septic tank for winter?

Leave your comments under our article - your experience of construction and operation homemade septic tank will be useful to many owners of private houses and summer cottages.

When installing a private sewer system on a site, owners of country houses or summer cottages previously used the method of constructing a standard sewage pit, which required periodic cleaning and at the same time gave an unpleasant odor to the entire area. However, today progress has gone far ahead and makes it possible not only to create high-quality wastewater reservoirs, but also to take care of the environment. At the same time, significant savings in the family budget in this case are not in last place. Such a perfect mechanism for wastewater treatment domestic water is a septic tank without pumping.

We will discuss below what this “beast” is, how septic tanks work without pumping, and what the principles of their construction are.

A septic tank is a special treatment facility consisting of two or three chambers connected to each other by overflow hoses. Such a system serves to collect domestic wastewater, settle it, further purify it and then transport it to the ground.

According to SNiP, household wastewater from a dacha, bathhouse, country house, etc., which has been treated through a settling tank, is considered suitable for discharge into nearby reservoirs, into the soil or roadside ditches. Since such liquid is purified in a septic tank by 90%.

The operating principle of such a system is as follows:

- Domestic wastewater flows through the sewer pipe into the first chamber of the tank - a sealed storage tank. This is where the settling happens. dirty water and its division into large heavy particles, which, under the influence of gravity, settle to the bottom, and more clarified water.

- After this, the light water is poured by gravity or using pumps into the second chamber of the treatment system, where it is further purified. Here again, larger particles of impurities settle to the bottom, and light water flows into a third, sealed drainage chamber. Here the chamber no longer has a bottom, but is equipped with a special filter made of crushed stone. Through it, purified water is simply sent to the ground.

Important: the main disadvantage of such a wastewater treatment system is its energy dependence and the need for regular cleaning (once a year) of sludge from the first and second settling tanks, which can give an unpleasant odor. But there is a solution here too - a septic tank without pumping and electricity.

How does the system work without pumping?

Septic tanks without pumping and electricity are analogues of the septic tanks described above, only main job They contain beneficial bacteria. They ensure high-quality processing of residual sludge, which allows you to avoid an unpleasant odor in the country and avoid the constant need to pump out residual sludge from the chambers of the septic tank. But about everything in detail.

A septic tank that handles wastewater without outside intervention is called a biological septic tank. Here, not only mechanical clarification of water occurs, but also its biological purification. As a result of this treatment, the wastewater is considered 98% purified.

Important: as a result of the work of bacteria, organic sludge also collects in the well. But its removal is carried out once every 5-7 years, which differs significantly from cleaning a standard mechanical septic tank. In addition, organic sludge from a biological septic tank does not pose any threat to the environment, does not have a pungent odor and can be used as fertilizer in the country.

A biological septic tank without pumping has a standard structure of two or three chambers. Just like in a standard treatment tank, wastewater first accumulates in the first chamber. Only here do oxygen and aerobic bacteria come into play, which, interacting with each other, contribute to more thorough water purification. That is, in addition to the fact that organic matter settles to the bottom, it also decomposes into its simplest components under the influence of aerobic bacteria.

Important: for high-quality work of bacteria in a septic tank for a summer residence without pumping, it is necessary to ensure a constant flow of oxygen into the first and second chambers. In addition, reliable ventilation will eliminate the possibility of spreading unpleasant odors in the country.

Advantages and disadvantages of a treatment plant without pumping

A biological septic tank without pumping has a number of advantages, the main of which are:

- High quality treatment of domestic wastewater in a country house or country house;

- No pungent odor of hydrogen sulfide in the area;

- The ability to hide the wastewater tank in the ground and not spoil the landscape design of the site;

- Saving the family budget;

- The ability of a septic tank to process wastewater containing household chemicals (except chlorine);

- Full compliance with all sanitary standards.

Important: the only disadvantage of such a structure is its cost. But it fully pays for itself during the operation of the structure.

What material is best to make biological septic tanks from?

To install a septic tank without pumping for a dacha, you can use either ready-made plastic tanks with thick walls and stiffeners, or prefabricated structures made of various materials. The most popular are:

- Concrete rings. Such elements for treatment wells are heavy, which completely eliminates washout due to rain or spring melting of snow. But concrete is a porous material, which does not exclude damage to the structure of the septic tank over time under the influence of aggressive environment. In addition, the tightness of a well assembled from concrete rings may be compromised over time, even if a special mastic-sealant is used. In addition, installing a concrete septic tank will require the use of special equipment, and this is not always convenient on site. Especially if the septic tank is located at the rear of the site and vehicle access there will be difficult.

- Brick . Simple brickwork also makes it possible to make chambers for a wastewater treatment plant. Brick septic tanks without pumping are quite durable and easy to install. But the hygroscopicity of brick can, over time, cause untreated waste to leak into the ground. Therefore, you either need to ensure that all masonry joints are thoroughly sealed, or use a more airtight material.

- Plastic containers or PVC rings. Ready-made structures made of durable plastic are widely used in the construction of septic tanks without pumping. Such reservoirs are analogues of the Topol biological station, which also operates without pumping. Plastic cubes or barrels can easily withstand squeezing or heaving of the soil, provided they are securely anchored to a concrete slab. Plastic tanks, like the Topol septic tank, last more than 100 years, are not subject to the aggressive effects of wastewater and have increased strength.

- You can also build a septic tank without pumping without electricity from old car tires subject to their integrity. Here the tires are mounted on top of each other like a well until the desired tank volume is reached.

Important: a septic tank made from tires is subject to deformation, which, in turn, can lead to its depressurization. Therefore, such a structure is suitable for installation in areas where the groundwater level is quite low. Otherwise, during the seasonal melting of snow or rain, the well will be washed out or compressed.

Important principles for installing a biological septic tank

In order for a septic tank without pumping without electricity to work effectively, several important principles must be adhered to at the stages of its design and installation. Otherwise, all efforts may soon simply come to naught, and then everything will have to be redone again.

- So, first of all, when building a septic tank, you need to correctly calculate its volume. To do this, the average figure is taken to be 200 liters per person per day according to SNiP rules. We multiply this number by three (the number of days during which there is an influx of wastewater into the septic tank chamber). We multiply the resulting result (600 l) by the number of people living in the house. For example, 3 people live in a house. This means 600x3=1800 l or 1.8 m3. Here you should round the volume up to the nearest whole number. Thus, for three people, a biological septic tank should have a volume of 2 m3. In this case, the result obtained must be divided by the number of chambers of the septic tank. So, if a two-chamber treatment system is assumed, then the first storage tank should be 3/4 of the total volume. If it is planned to build a three-chamber septic tank for a summer residence, then the volume of the first storage chamber can be 2/3 of the total volume.

- The first two chambers of the septic tank must be sealed. The third (or last chamber, depending on the design of the septic tank) is made with a drainage bottom. A layer of crushed stone acts as drainage.

Important: To increase the drainage area, you can remove perforated pipes from the third chamber of the treatment plant, through which clarified water will be sent into the ground.

- The septic tank must be located away from all residential and utility rooms, and also away from neighbor's fence and a water-bearing source. The rules are prescribed in SNiP. So, the septic tank should be located at least 8-10 meters from the house. From a well or well - 30-50 meters. From a natural reservoir - 30 meters. From the neighbor's fence - at least 3 meters. Also, when constructing a treatment plant, it is imperative to take into account the direction of movement of groundwater.

Security reliable operation biological septic tank

In order for the septic tank to work without failures, it is necessary to ensure it correct installation. In addition, preventive maintenance will be required. Some confident summer residents resort to tricks that allow them to control the operation of the sump.

- To eliminate the risk of drain overflow, water level monitoring sensors are installed.

- If a biological septic tank is not used regularly, then there is a risk of bacteria dying out. In order to awaken them or resume the operation of the septic tank, you will have to purchase bacteria from a specialized store and run them through sewer pipe along with sufficient water and air.

- Sometimes bacteria can stop their action due to insufficient air. Here it will be necessary to improve the oxygen flow system, otherwise the efficiency of the septic tank will be minimal.

Important: if you do not want to bother with setting up a biological treatment system without the need for pumping and without consuming electricity, then you can simply purchase a biological station that operates without any human intervention. The Topol stations have proven themselves to be excellent in this case.

About Topol stations

Biological septic tank stations "Topol" - advanced equipment for the treatment of household wastewater. The Topol equipment has the form of a monolithic plastic tank, internally divided into four chambers. The station is equipped with special bacteriological filters, overflow hoses, a compressor and a ventilation system. Thus, the Topol septic tank independently copes with household wastewater, subsequently draining it into the ground.

Depending on the amount of wastewater processed, all Topol stations are divided into the following models:

- "Topol" 5 - a septic tank for 5 or less people living in the house. The station processes 1 m3 of water per day and can receive up to 250 liters of water at a time.

- "Topol"-8. Treatment facility for 8 or less people living in the house. The station processes 2 m3 of water.

- Station "Topol"-10. It is used in conditions of increased complexity and is designed to treat more than 3 m3 of wastewater per day.

In any case, Topol stations consume 1.2 kW/hour, which makes them quite economical.

Important: salespeople at specialized sales points will always help you choose a high-quality treatment station for household waste.